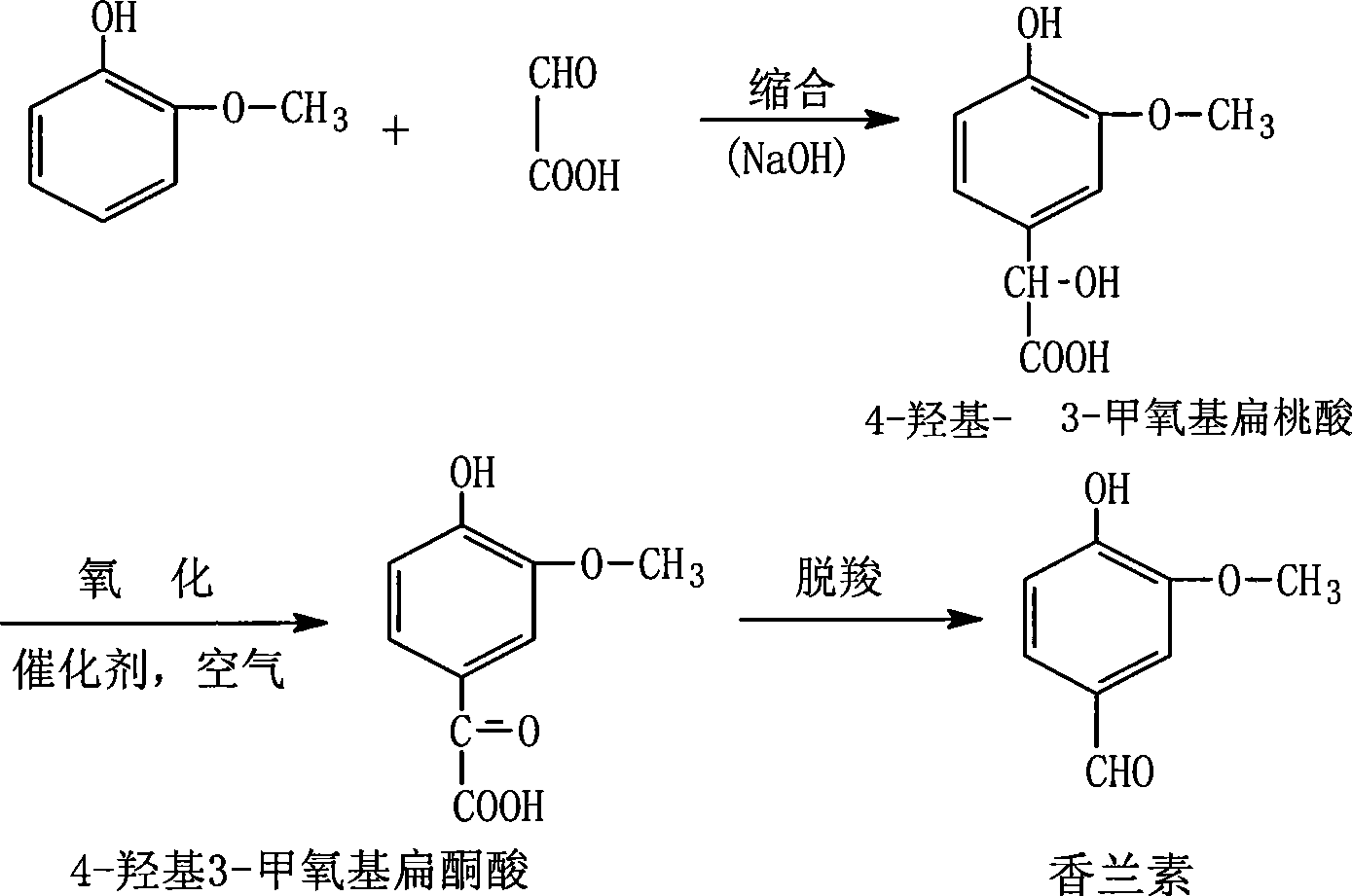

Carbon dioxide supercritical continuous extraction of vanillic aldehyde and derivates thereof from acidic water solution

An acidic aqueous solution, carbon dioxide technology, applied in the separation/purification of carbonyl compounds, bulk chemical production, organic chemistry, etc. The effect of continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The carbon dioxide gas with a purity of 99.5% is pressed in from the bottom of the extraction column through a high-pressure plunger pump at a flow rate of 15kg / h, and the extraction pressure is controlled to 24MPa and the extraction temperature is 55°C. Then start the liquid high-pressure plunger pump, and press the 3.3% vanillin acid aqueous solution from the storage tank into the top of the extraction column. The liquid flow rate is 4.0Kg / h, so that the two fluids are in countercurrent continuous contact in the extraction column. The carbon dioxide fluid with vanillin passes through the top of the extraction column to the separation tank 1 for decompression. The separation tank 1 has a control pressure of 6.0MPa and a temperature of 55°C. After decompression, the vanillin remains at the bottom of the separation tank and the carbon dioxide gas Enter the separation tank 2 for decompression, control the pressure at 5.3MPa, and control the temperature at 32°C. The separated ...

Embodiment 2

[0026] Proceed as in Example 1. The carbon dioxide gas with a purity of 99.5% is pressed in from the bottom of the extraction column through a high-pressure plunger pump at a flow rate of 20kg / h, and the extraction pressure is controlled to 22MPa and the extraction temperature is 60°C. Then the liquid high-pressure plunger pump is started, and a 3.3% acidic aqueous solution of vanillin dissolved in the storage tank is pressed into the top of the extraction column, and the liquid flow rate is 3.8Kg / h. The carbon dioxide fluid with vanillin passes through the top of the extraction column to the separation tank 1 for decompression. The separation tank 1 has a control pressure of 5.7MPa and a temperature of 55°C. After decompression, the vanillin remains at the bottom of the separation tank and the carbon dioxide gas Enter the separation tank 2 for decompression, control the pressure at 5.0 MPa, control the temperature at 30°C, and run for 18 hours dynamically, stop the extraction, an...

Embodiment 3

[0028] Proceed as in Example 1. The carbon dioxide gas with a purity of 99.5% is forced in from the bottom of the extraction column through a high-pressure plunger pump at a flow rate of 20kg / h, the extraction pressure is controlled to 30MPa, the extraction temperature is 45°C, and the liquid flow rate is 3.0Kg / h. Control the pressure of separation tank 1 to 6.0MPa and control the temperature to 45℃. After decompression, the vanillin stays at the bottom of the separation tank, and the carbon dioxide gas enters the separation tank 2 for decompression. The control pressure is 5.0MPa, the control temperature is 30℃, and the dynamic operation is 18 hour. The vanillin content in the separation tank 1 was analyzed by high performance liquid chromatography to be 92.87%, the vanillin content in the water phase was 0.063%, and the extraction efficiency was 94.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com