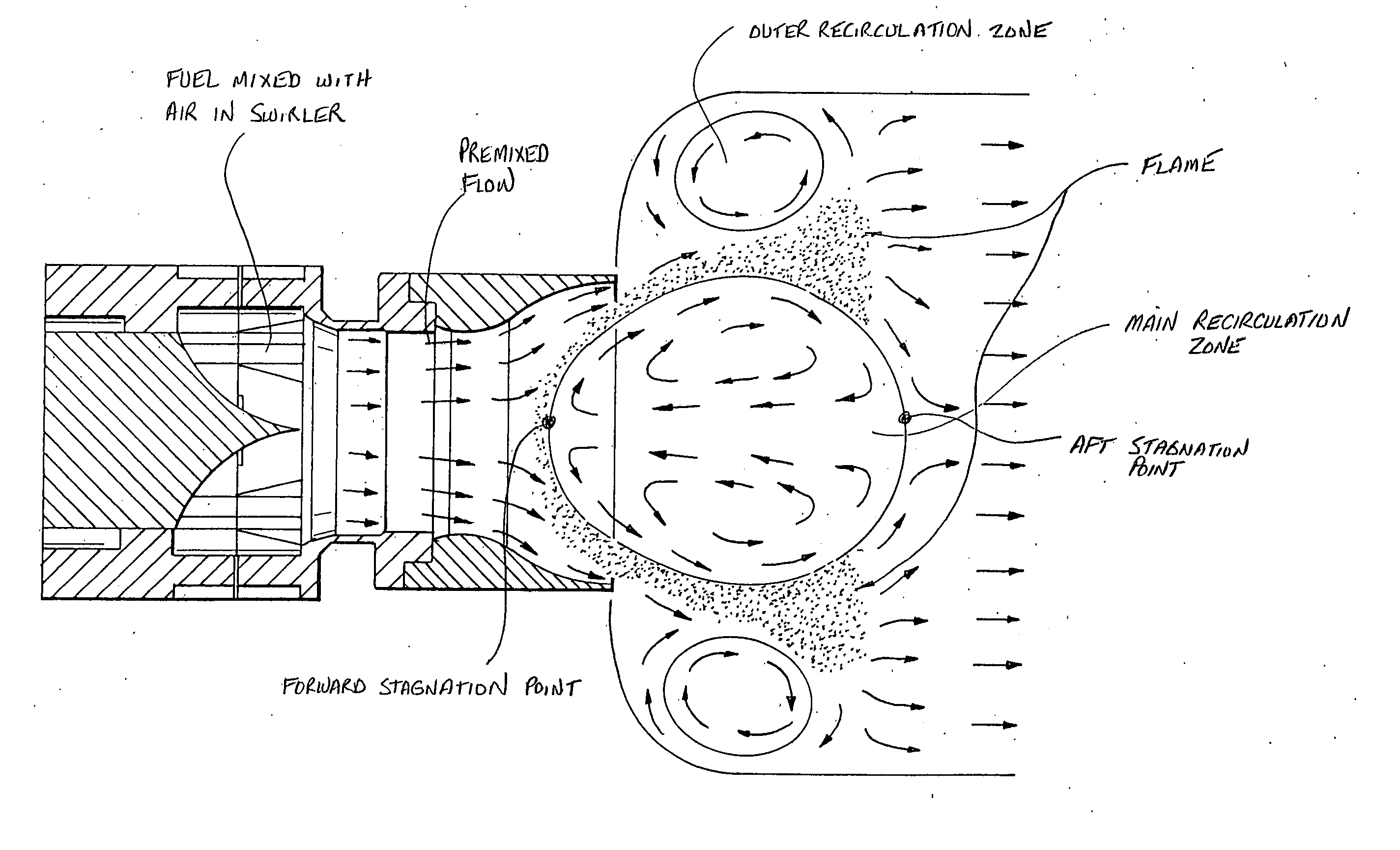

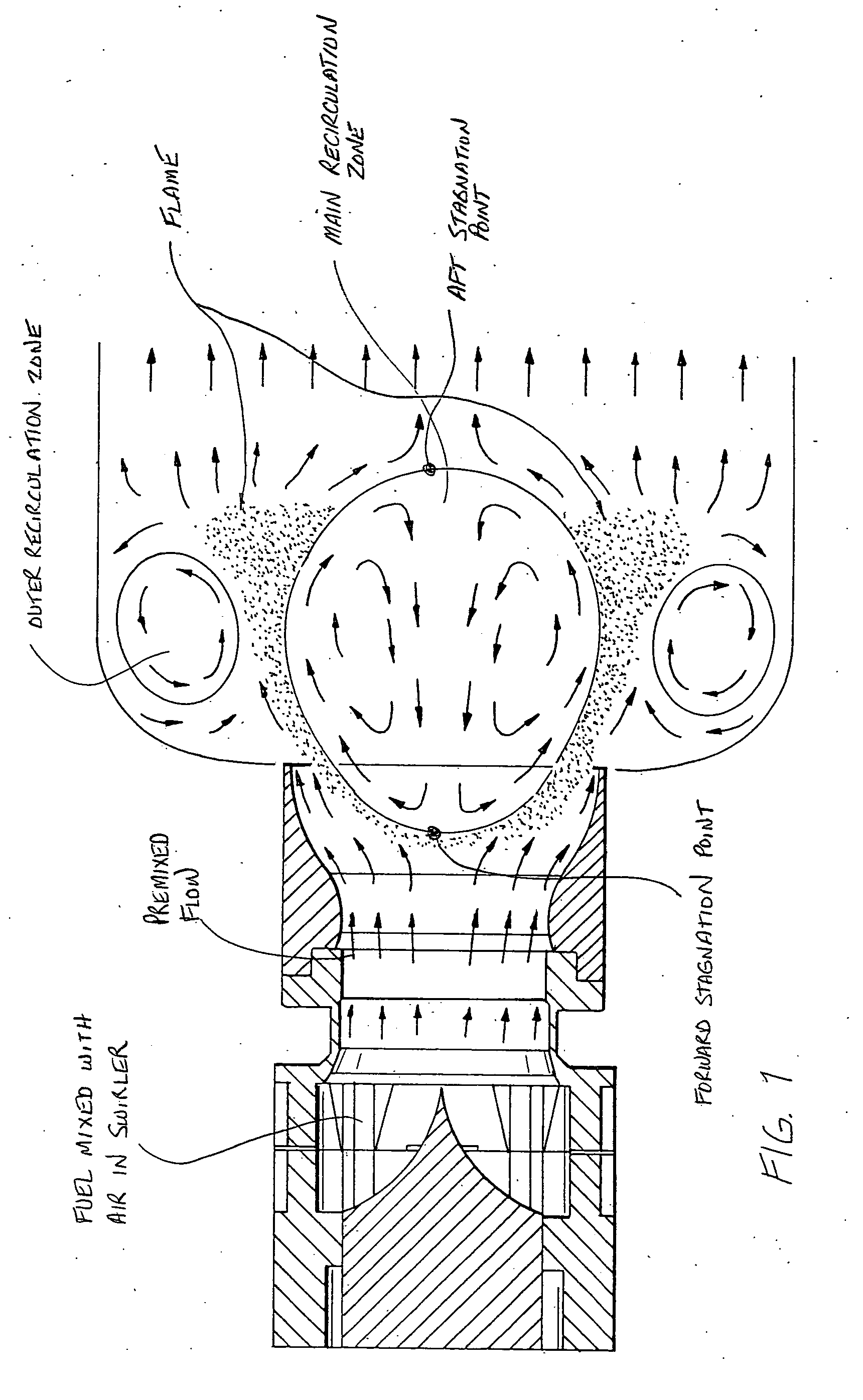

Device for stabilizing combustion in gas turbine engines

a gas turbine and combustion engine technology, applied in the direction of burner details, combustion types, lighting and heating apparatuses, etc., can solve the problems of low flux of hot and chemically reactive combustion products that are transported upstream, polluted emissions, nitrogen oxides,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

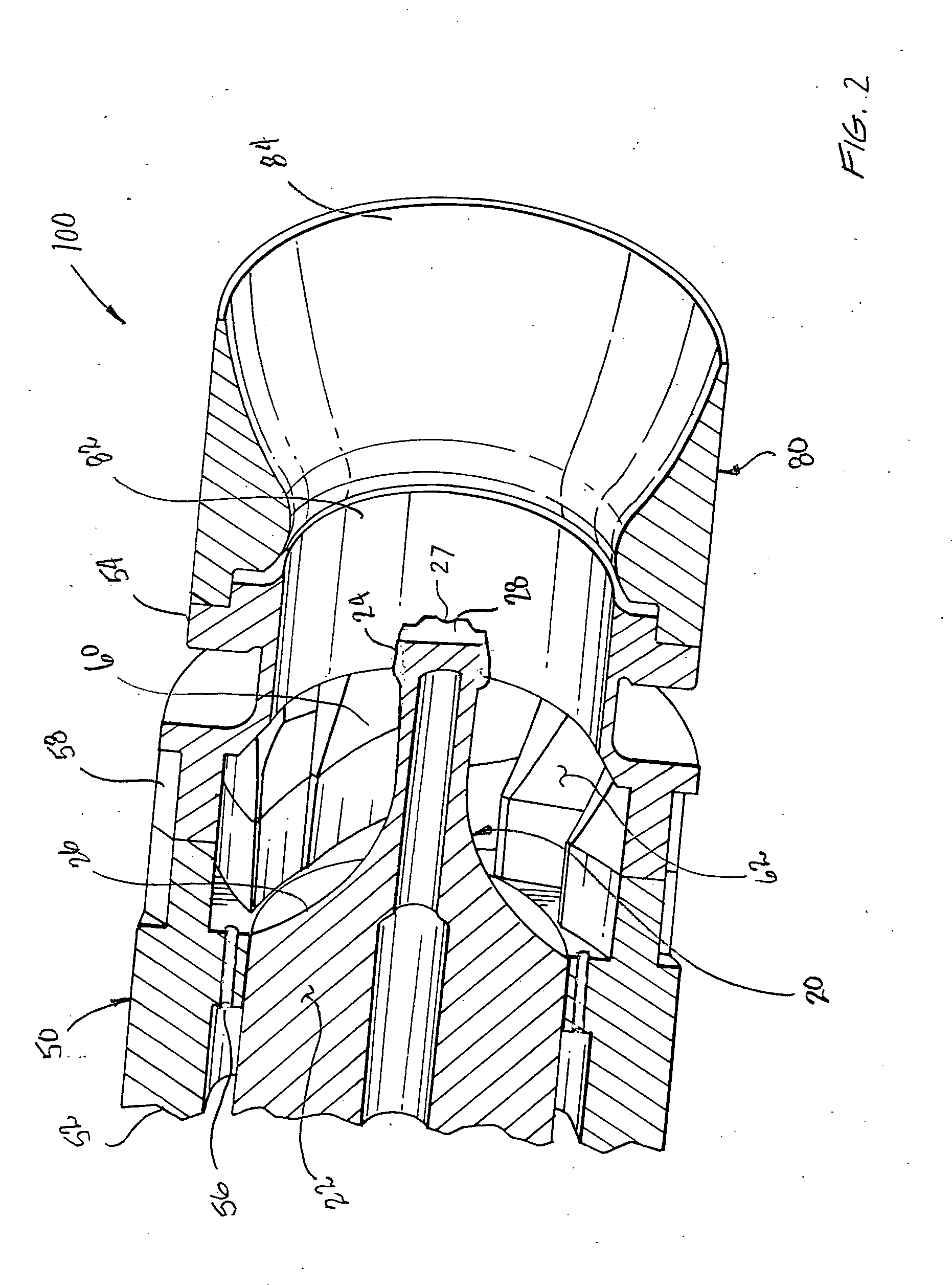

[0035] Referring now to the drawings wherein like reference numerals identify similar structural aspects of the subject invention, there is illustrated in FIG. 2 a burner for a gas turbine combustor designated generally as reference numeral 100. Burner 100 uses a central bluff body flame holder 20 and a quarl device 80 to stabilize the combustion process. The burner 100 includes, among other elements, a cylindrical main body 50, a flame holder 20 and a quarl device 80. The main body 50 and the flame holder 20 may be attached to one another in a conventional manner, or held together by an interference fit, or mechanically interlocked.

[0036] The burner main body 50 includes axially opposed upstream and downstream end portions, 52 and 54, respectively. A plurality of axially-oriented fuel inlet passages 56 and a plurality of radially-oriented air inlet passages 58 are formed in main body 50. Those skilled in the art would readily appreciate that the location, quantity and orientation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com