High-permeability anion modified emulsified asphalt and preparation method thereof

An anionic modification and anionic emulsifier technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of difficult to guarantee the bonding strength and difficult to determine the impact of the base layer, so as to improve capillary penetration and service life , the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

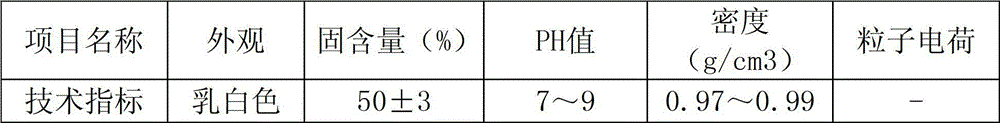

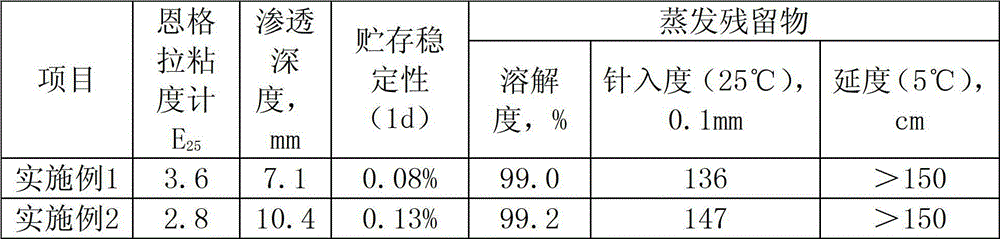

[0041] First weigh 450g of Esso No. 110 road petroleum asphalt, and add 30g of diluent in the asphalt hot-melt state (120-140°C) (the diluent is mixed with self-refined processed light oil and white oil in a mass ratio of 1:1) , mechanically stir (about 10 minutes) and mix well, then add soap solution at 50-70°C, and then emulsify in asphalt emulsification equipment (colloid mill) to obtain the finished high-permeability anion-modified emulsified asphalt. The soap liquid consists of 450g water, 15g emulsifier (the emulsifier is mixed with sodium lauryl sulfate and AES at a mass ratio of 4:1), 1.5g sodium hydroxide, 33.5g anionic SBR latex 6516 and 20g fatty alcohol polyoxyethylene ether (Penetrant JFC-E from Jiangsu Haian Petrochemical Plant), and the obtained product meets the technical specifications of anionic emulsified asphalt required by JTG F40-2004. The main specifications are shown in Table 2.

Embodiment 2

[0043]Weigh 400g of petroleum asphalt from West Petrochemical No. 70 Road, and add 35g of diluent in the asphalt hot-melt state (120-140°C) (the diluent is made of self-refined white oil, crude residue, and processed light oil at a ratio of 1:1: 1 mass ratio mixing), mechanical stirring (about 10 minutes) after mixing evenly, add soap liquid at 50-70°C, and then emulsify in asphalt emulsification equipment (colloid mill) to obtain the finished high-permeability anion-modified emulsified asphalt. The soap liquid is composed of 500g water, 10g emulsifier (the emulsifier is mixed with sodium cetyl sulfonate and sodium α-olefin sulfonate in a mass ratio of 3:2), 2g stabilizer (the stabilizer is composed of sodium hydroxide and zinc oxide Mixed according to the mass ratio of 1:1) and 38g of anionic SBR latex 6516 and 15g of alkylphenol polyoxyethylene ether (penetrant JFC-M of Jiangsu Haian Petrochemical Plant), and the obtained product meets the requirements of JTG F40-2004 specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com