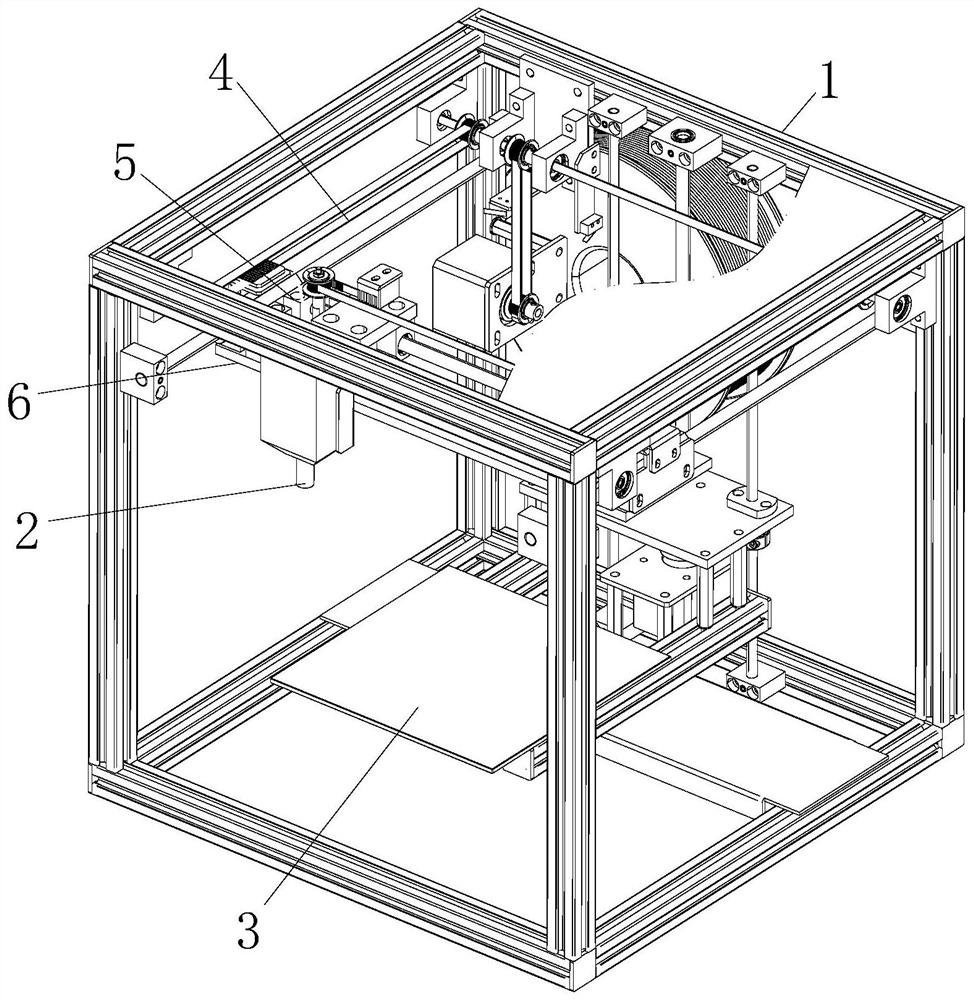

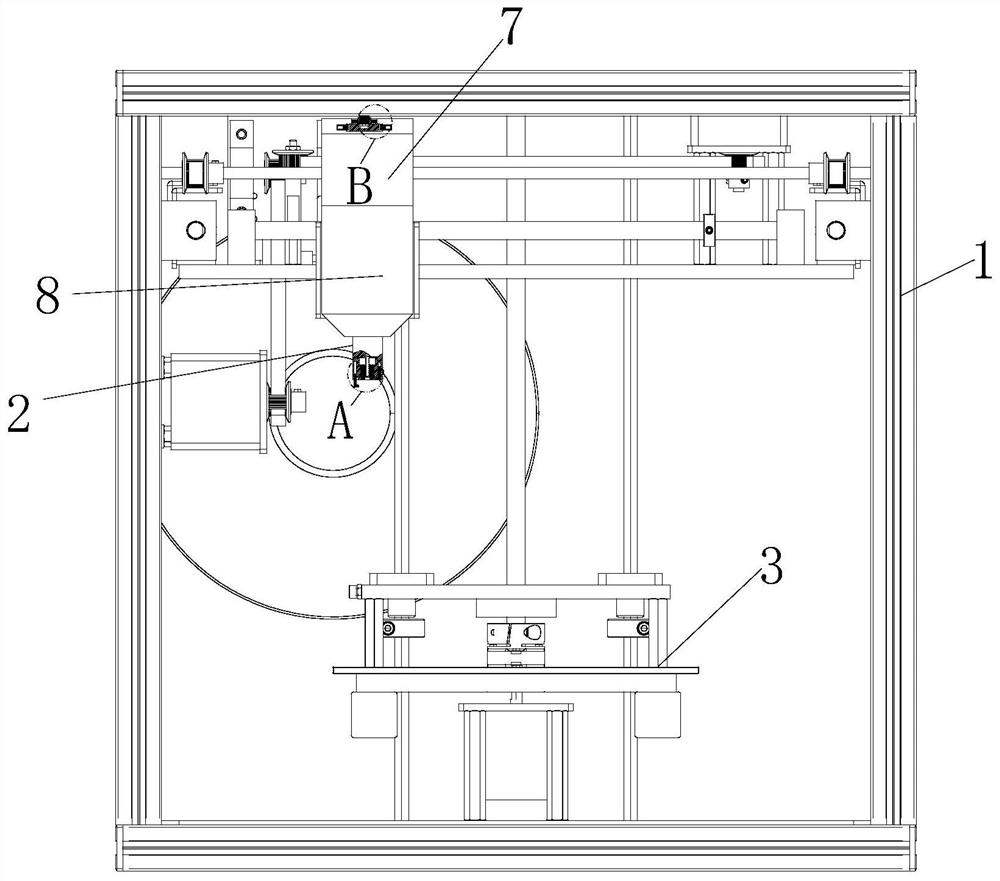

Multi-material 3D printer

A 3D printer, multi-material technology, applied in 3D object support structure, additive processing, additive manufacturing, etc., can solve the problems of easy dripping of materials, high wire drawing cost, and formation of wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

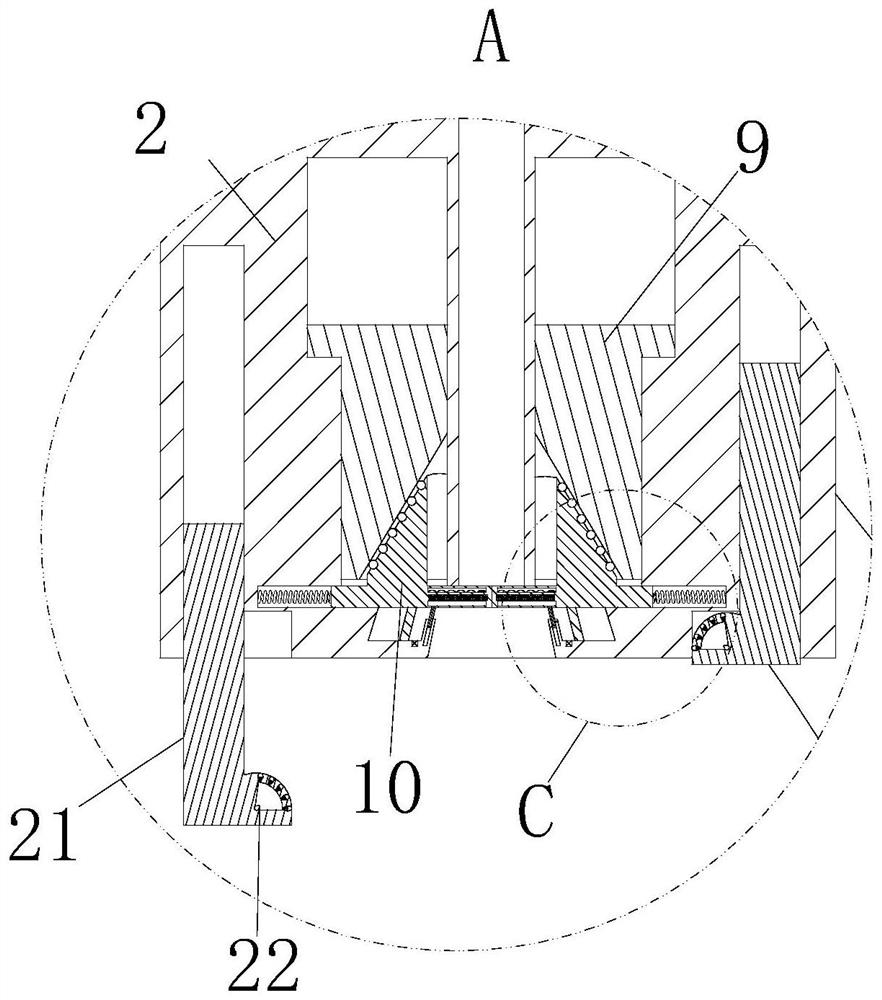

[0034] As an embodiment of the present invention, the bottom surface of the guide groove is provided with a storage slot near the nozzle hole; the bottom surface of the mouth of the storage slot is provided with a chute; the inside of the chute slides A scraper 18 is connected; when working, by setting the scraper 18, when the nozzle 2 switches positions, the air source is introduced into the guide groove at the same time, and when the guide blocks 10 retract and slide, the guide block 10 will contact the scraper. 18 to move relative to each other, thereby realizing the automatic cleaning of the solidified molten material on the bottom surface of the guide block 10. At the same time, when the guide block 10 is separated, the scraper 18 will be put into the corresponding guide groove. At this time, the solidified molten material can be automatically introduced into the storage tank. internal.

[0035] As an embodiment of the present invention, the bottom surface of the guide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com