Calcium carbide liquid jet granulation and waste heat utilization system and method

A calcium carbide and granulation technology, applied in the chemical industry, can solve the problems of a large amount of calcium carbide dust, slow cooling speed of calcium carbide ingots, economic losses, etc., and achieve the effects of complete recovery and comprehensive utilization, saving crushing steps, and avoiding dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

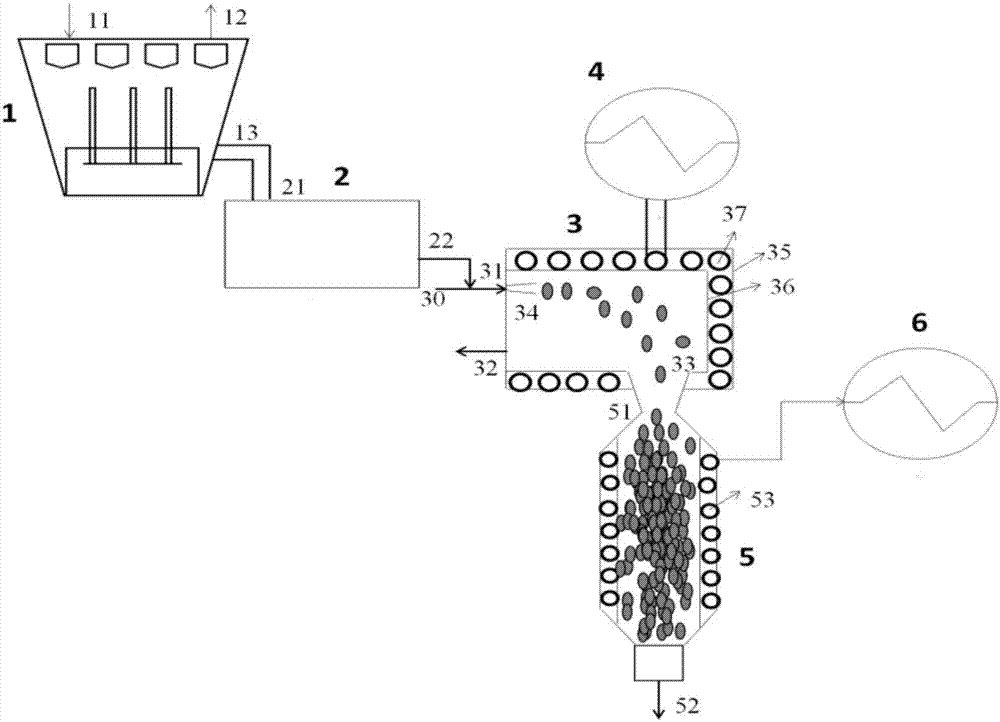

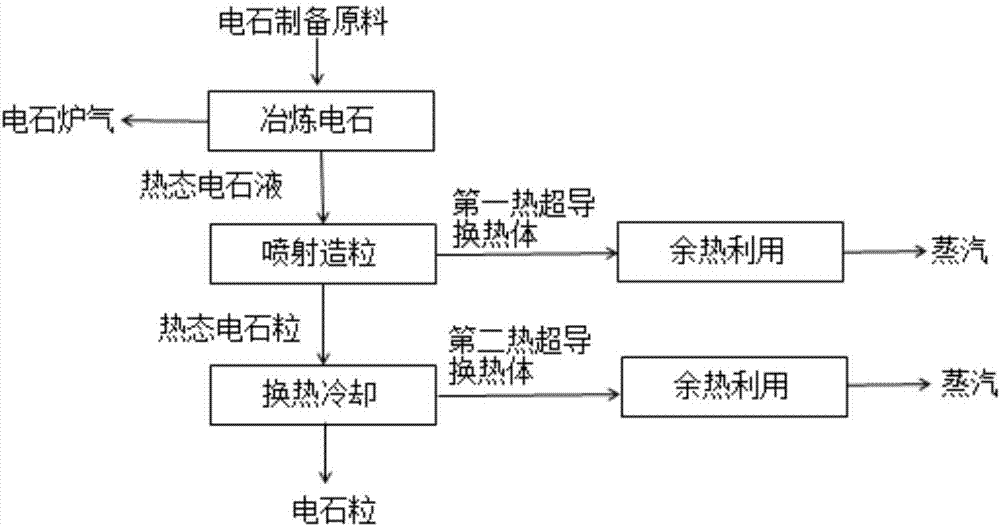

[0049] The calcium carbide furnace smelts calcium carbide to obtain hot calcium carbide liquid at a temperature of 2000-2200 °C. The hot calcium carbide liquid flows directly from the nozzle of the calcium carbide furnace to the calcium carbide liquid insulation storage tank, and then enters the high-pressure air pipeline and enters under the pressure of high-pressure air. Injector, and spray into the jet granulation device through the nozzle of the injector. The side wall of the spray granulation device is provided with a first thermal superconducting heat exchanger, and the hot calcium carbide liquid exchanges heat with the first thermal superconducting heat exchanger, and the hot calcium carbide liquid is rapidly cooled and granulated to obtain hot calcium carbide granules. A thermal superconducting heat exchange body absorbs the heat of the hot calcium carbide liquid and heats up to heat the first steam boiler to obtain steam. Then, the hot calcium carbide grains are direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com