Lithium ion battery

A lithium-ion battery and carbon number technology, applied in the field of lithium-ion batteries, can solve problems such as poor performance of lithium-ion batteries, improve capacity retention rate and cycle stability, excellent safety performance, and ensure high temperature and normal temperature cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-7

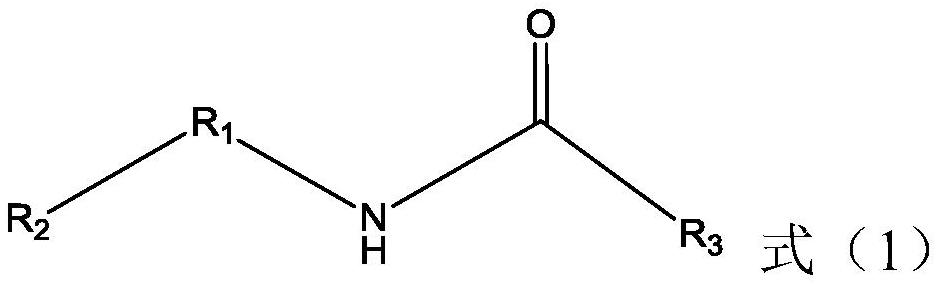

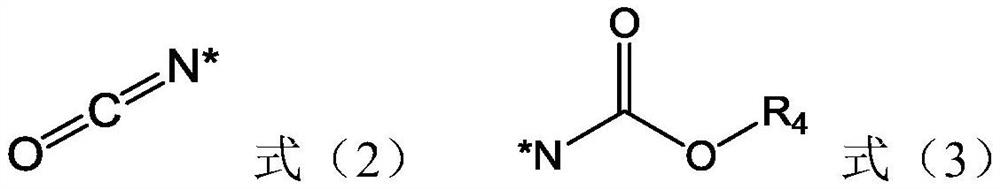

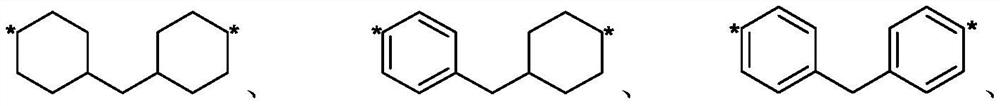

[0129] Preparation Examples 1-7: Preparation of Compounds

[0130] Under 25 DEG C, the raw material compound A in Table 1 and the raw material compound B were carried out amidation reaction with the molar ratio of 1:1 respectively for 10 hours, and triethylamine was used as the acid-binding agent (the ratio of triethylamine and raw material compound A) in the reaction The molar ratio is 1.5:1), and compound 1, compound 2, compound 3, compound 4, compound 6, compound 7 and compound 12 were prepared by column chromatography purification after the reaction.

[0131] Table 1

[0132]

[0133]

[0134]

[0135]

preparation example 8

[0136] Preparation Example 8: Preparation of PVDF Coated Separator

[0137] PVDF is added in acetone with respect to the amount of 5% by weight of acetone, and is dissolved at 50 ℃ for 12 hours, prepares PVDF slurry; PVDF slurry is coated on the one side of Celgard2400 separator (thickness is 20 μ m), after Dry in an oven at 60° C. for 12 hours, and the thickness of the dried coating is 2 μm.

preparation example 9

[0138] Preparation Example 9: Al 2 o 3 Preparation of coated separators

[0139] PVDF was added in acetone in an amount of 5% by weight relative to acetone, and dissolved at 50° C. for 12 hours to prepare a PVDF mixed solution; the Al 2 o 3 Particles (with a particle size of 0.2 μm) were added to the PVDF mixture, in which Al 2 o 3 The weight ratio of particles to PVDF is 9:1, and Al 2 o 3 slurry; Al 2 o 3 The slurry was coated on one side of a Celgard 2400 separator (20 μm in thickness), and then dried in an oven at 60° C. for 12 h, and the thickness of the dried coating was 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com