Tightly-arranged engine tail gas treatment system

An exhaust gas treatment and engine technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of low treatment efficiency, difficult to install after-treatment systems, poor stability, etc., so as to improve catalytic efficiency, facilitate full utilization, Guaranteed effect at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

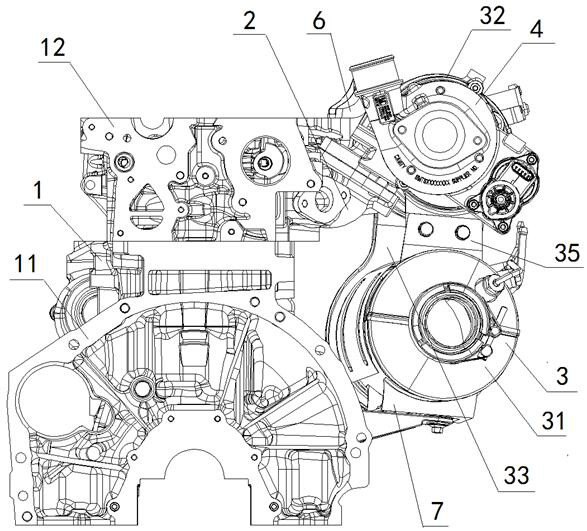

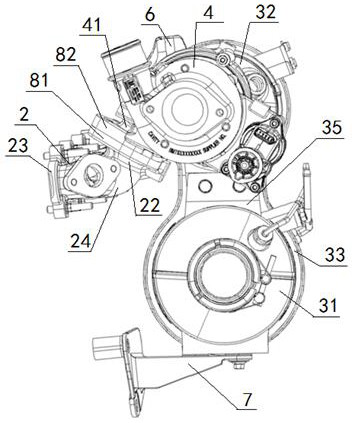

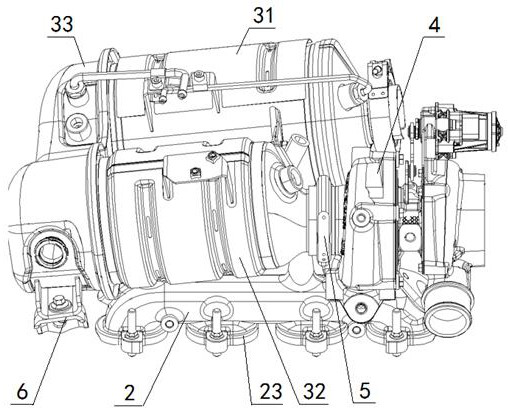

[0068] The exhaust manifold 2, the aftertreatment assembly 3 and the supercharger 4 are all fixedly arranged on one side of the engine 1; the aftertreatment assembly 3 includes a selective catalytic reduction particulate matter trap 31, an oxidation catalyst 32 And the mixer assembly 33, the selective catalytic reduction particulate matter trap 31 is located below the oxidation catalyst 32, the rear end of the selective catalytic reduction particulate matter trap 31 passes through the mixer assembly 33 and the oxidation catalytic converter The rear end of 32 is connected, and the selective catalytic reduction particulate matter trap 31, oxidation catalyst 32 and mixer assembly 33 are arranged in a U shape; the exhaust manifold 2 is arranged between the engine 1 and the oxidation catalyst 32 , the front of the exhaust manifold 2 communicates with the front end of the oxidation catalyst 32 through the supercharger 4, and the exhaust manifold 2 and the particulate matter trap 31 f...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0071]The engine 1 includes a cylinder block 11 and a cylinder head 12 fixedly arranged on the top of the cylinder block 11, the top of the mixer assembly 33 is connected with the cylinder head 12 through the upper fixing bracket 6, and the bottom of the oxidation catalyst 32 is The side of the cylinder block 11 is connected through the lower fixing bracket 7; one side of the exhaust manifold 2 has a plurality of manifold inlets 21 corresponding to the engine exhaust ports, and the manifold inlets 21 is sealed with the engine exhaust port on the side of the cylinder head 12, the manifold inlet 21 is provided with a manifold mounting flange 23, and the exhaust manifold 2 is fixed on the cylinder head 12 through the manifold mounting flange 23; The front end of the oxidation catalyst 32 is fixedly provided with an after-treatment assembly inlet flange 34; the turbine outlet end of the supercharge...

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0074] The outer walls of the supercharger 4 and the exhaust manifold 2 are covered with a heat insulating layer;

[0075] The bottom of the front end of the oxidation catalyst 32 is connected as a whole with the top of the front end of the selective catalytic reduction particulate matter trap 31 through an auxiliary bracket 35 , and a hot air stagnation area 36 is formed between the auxiliary bracket 35 and the mixer assembly 33 The rear end of the selective catalytic reduction particulate matter trap 31 communicates with the rear end of the oxidation catalyst 32 through the mixer assembly 33, and the front end of the selective catalytic reduction particulate matter trap 31 is sealed with the vehicle exhaust tailpipe Connect; the supercharger 4 includes a compressor part and a turbine part, the front end of the turbine part is fixedly connected with the rear end of the compressor part, the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com