An oxygen supply heat insulation device and a combustible gas combustion chamber with the device

A technology of heat insulation device and combustion chamber, applied in the direction of combustion method, combustion equipment, combustion air/fuel supply, etc., can solve the problems of insufficient combustible gas combustion, heat loss, environmental pollution, etc., to avoid heat loss, Improved life and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

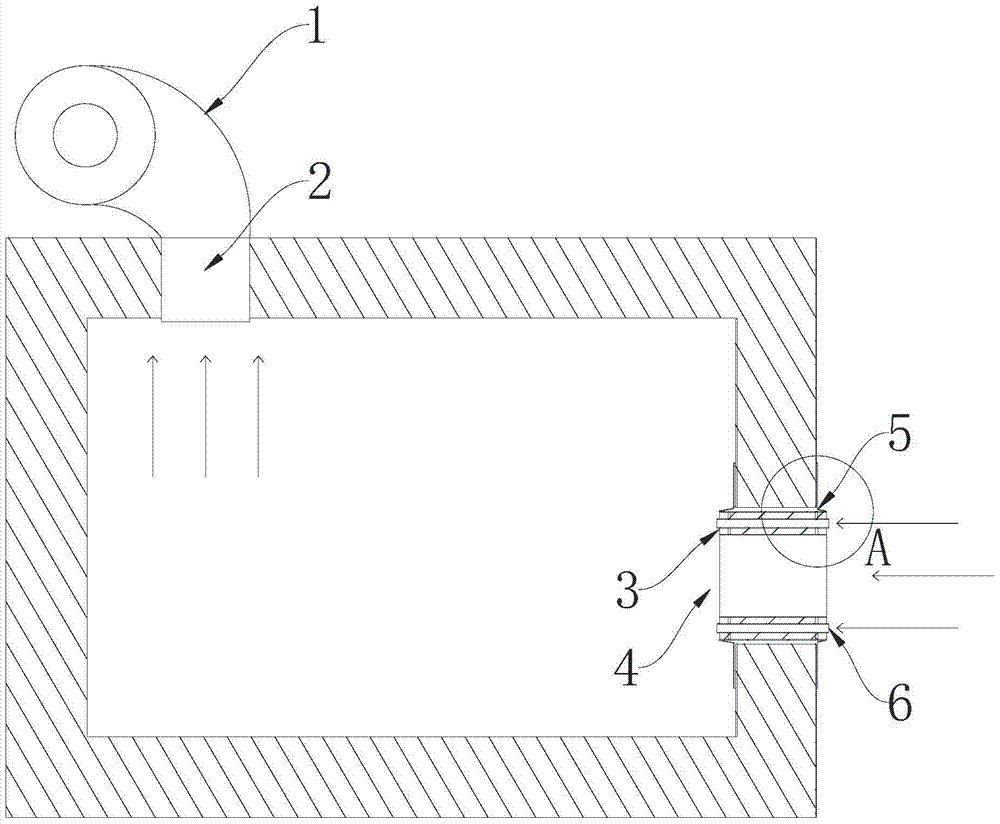

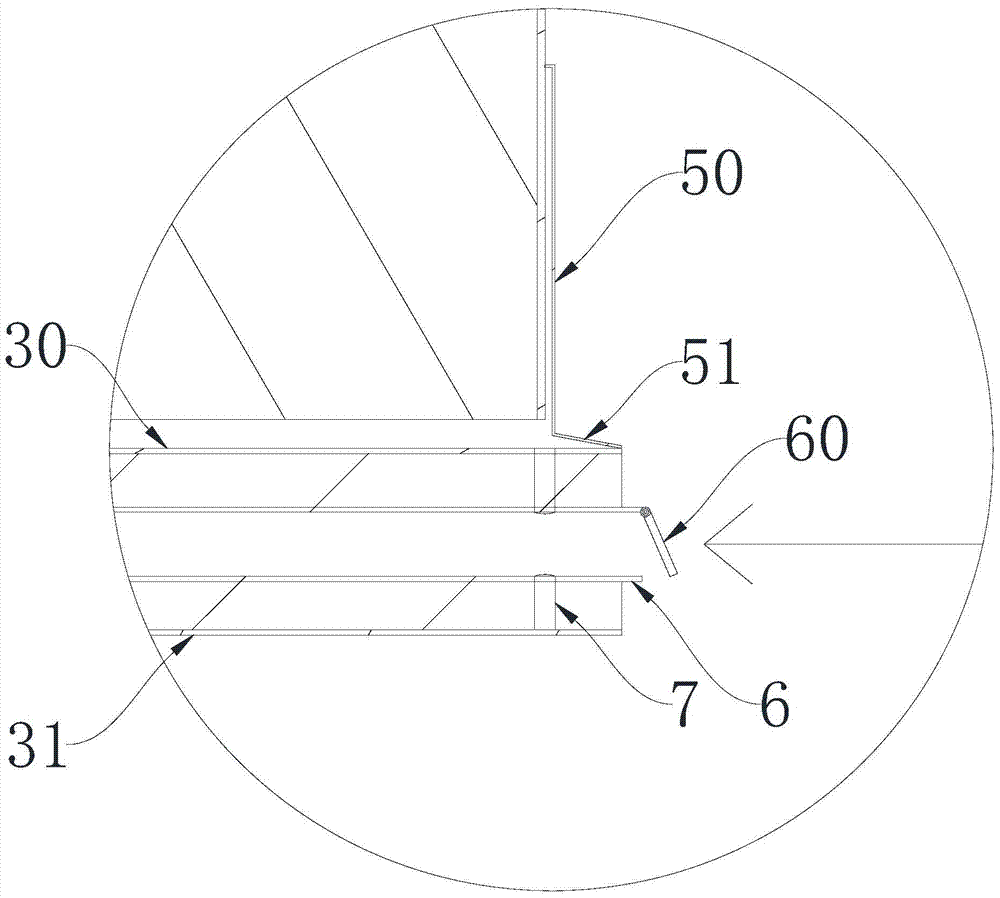

[0037] Such as figure 1 , 2, 3, the present invention discloses a heat insulation device for oxygen supply. When the device is in use, it is embedded in the combustion chamber inlet 4, and includes an air intake cylinder 3 whose two ends are respectively connected to the combustion chamber cavity and the flame injection port of the combustion device. 3 includes an inner cylinder 31 and an outer cylinder 30 nested with each other, the diameter of the outer cylinder 30 is larger than that of the inner cylinder 31, a support ring 7 is provided between the inner cylinder 31 and the outer cylinder 30, and the space between the inner cylinder 31 and the outer cylinder 30 is filled with The temperature-resistant castable is inserted with a plurality of oxygen supply pipes 6, the inner cylinder 31, the outer cylinder 30 and the oxygen supply pipes 6 are fixed to each other through the support ring 7, and the air intake end of the oxygen supply pipe 6 is installed to monitor the amount...

Embodiment 2

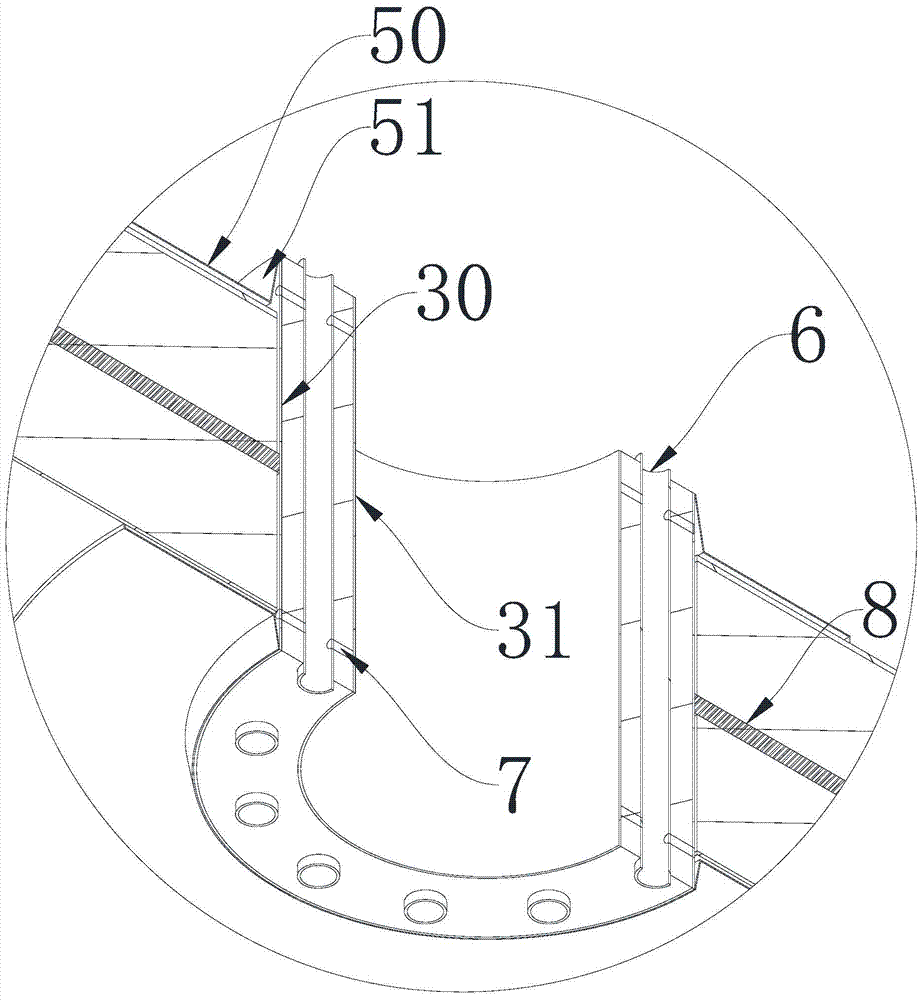

[0046] Such as Figure 4 , 5 , 6, this embodiment provides an oxygen supply heat insulation device with the same concept as Embodiment 1 and a combustible gas combustion chamber with the device. The oxygen supply heat insulation device can be embedded in the combustion chamber inlet 4, including two ends respectively The air intake cylinder 3 that communicates with the combustion chamber and the combustible gas pipe.

[0047] The difference between this embodiment and Embodiment 1 is that the air intake cylinder 3 is an air intake cylinder 3 formed by pouring a heat-resistant castable, and a plurality of supporting rings 7 connected with the combustion chamber inlet 4 are embedded inside the pipe wall of the air intake cylinder 3, and along the air intake cylinder 3 In the axial direction, a plurality of oxygen supply pipes 6 are inserted in the pipe wall of the air inlet cylinder 3, and the oxygen supply pipes 6 penetrate the heat-resistant castable and the support ring 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com