Preparation method of high-strength nylon

A high-strength, nylon technology, applied in the field of high-strength nylon preparation, can solve the problems of internal stress deformation, insufficient nylon strength, etc., to achieve the effect of increasing strength, increasing temperature, and slowing down injection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

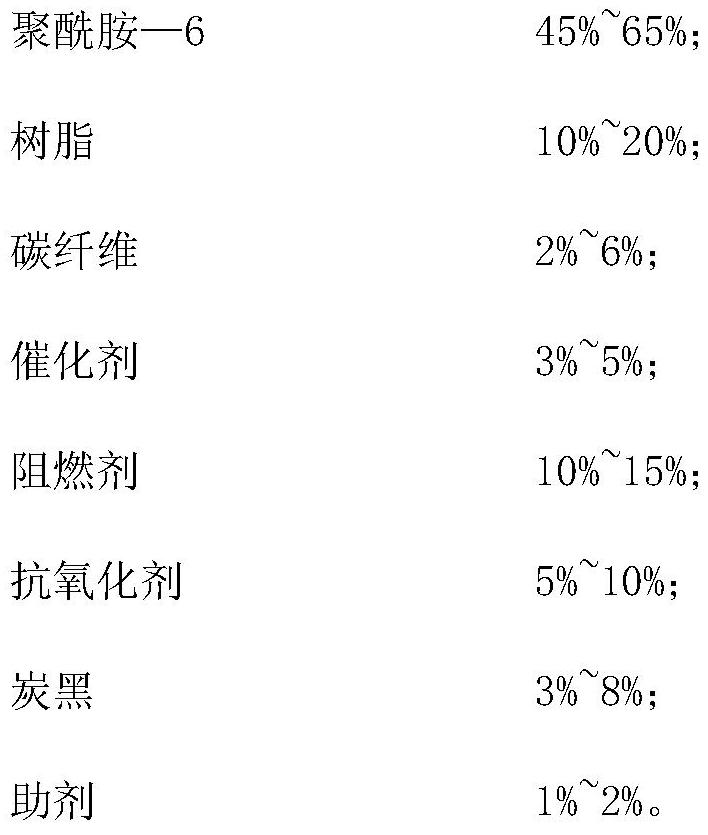

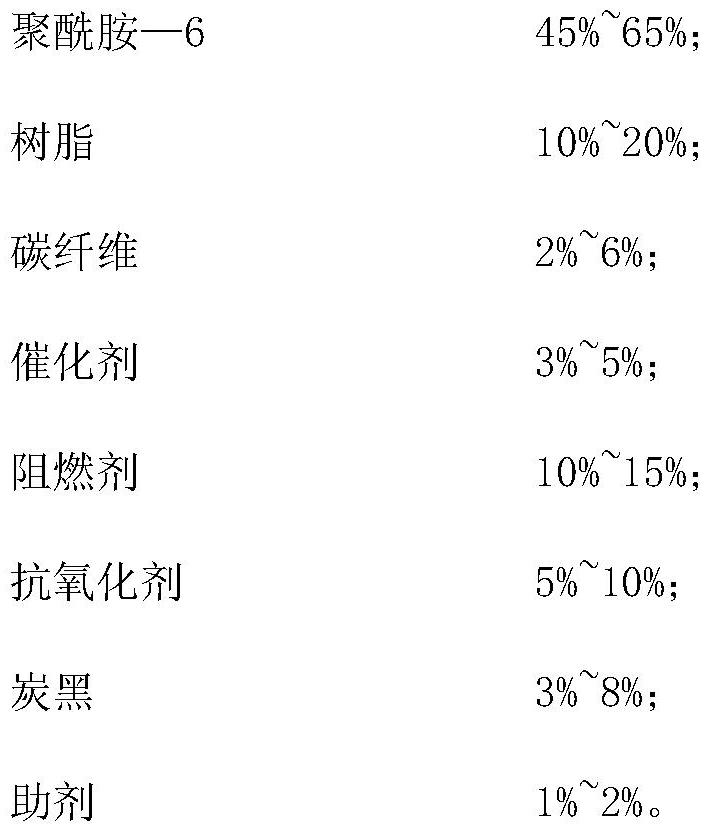

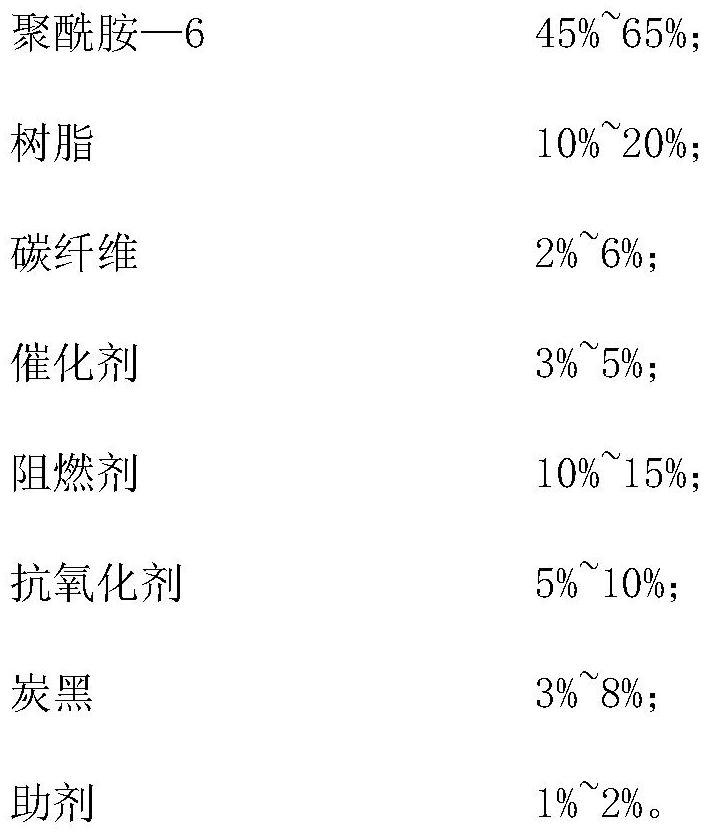

[0030] The invention discloses a preparation method of high-strength nylon, comprising the following steps:

[0031] Step 1: Pack the polyamide-6 in a vacuum bag. When in use, put the polyamide-6 into the dryer and dry it at a high temperature of 200-300°C. After drying, filter the impurities in the polyamide-6 with a nylon filter. ;

[0032] Step 2: Heat the resin at 200°C, mix it with polyamide-6 after heating, let it stand for 20 minutes, add carbon fiber and stir for 30-40 minutes;

[0033] Step 3: Add antioxidants to the above mixture, stir and let stand, add flame retardant, stir for 20-30 minutes, let stand for 30 minutes, add additives and stir;

[0034] Step 4: Ensure that the processing temperature is maintained at 300-320°C, add carbon black, stir for 25-30 minutes and then let stand;

[0035] Step 5: During injection molding, prolong the injection molding time, the injection speed is 50-60 cubic centimeters per second, add a catalyst during injection molding, and...

Embodiment 1

[0049]A preparation method of high-strength nylon, comprising the following steps:

[0050] Step 1: Pack 45% polyamide-6 in a vacuum bag. When in use, add polyamide-6 to a dryer and dry at a high temperature of 200°C. After drying, filter the impurities in polyamide-6 with a nylon filter ;

[0051] Step 2: Heat 10% polyethylene or polyoxymethylene at 200°C, mix with polyamide-6 after heating, add 2% carbon fiber and stir for 30 minutes after standing for 20 minutes;

[0052] Step 3: Add 5% anti-oxidant pentaerythritol dioctadecyl diphosphite or distearyl pentaerythritol diphosphite to the above mixture, add 10% phosphorus flame retardant after stirring and let it stand for 20 minutes For 30 minutes, according to the ratio of 1:1:1:1, add toughening agent, release agent, ultraviolet absorber and heat stabilizer in turn and stir. The toughening agent is polypropylene, and the ultraviolet absorber is phenyl o-hydroxybenzoate. , the mold release agent adopts zinc stearate, and t...

Embodiment 2

[0056] A preparation method of high-strength nylon, comprising the following steps:

[0057] Step 1: Pack 55% polyamide-6 in a vacuum bag. When in use, add polyamide-6 to a dryer and dry at a high temperature of 250°C. After drying, filter the impurities in polyamide-6 with a nylon filter ;

[0058] Step 2: Heat 15% polyethylene or polyoxymethylene at 200°C, mix with polyamide-6 after heating, add 2% to 6% carbon fiber after standing for 20 minutes and stir for 35 minutes;

[0059] Step 3: Add 6% antioxidant pentaerythritol dioctadecyl diphosphite or distearyl pentaerythritol diphosphite to the above mixture, add 12.5% phosphorus flame retardant after stirring for 25 minutes and let stand For 30 minutes, according to the ratio of 1:1:1:1, add toughening agent, release agent, ultraviolet absorber and heat stabilizer in turn and stir. The toughening agent is polypropylene, and the ultraviolet absorber is phenyl o-hydroxybenzoate. , the mold release agent adopts zinc stearate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com