Set-off shell material for fireworks and crackers and preparation method thereof

A shell material, fireworks and firecrackers technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of easy deformation of the shell of fireworks, affecting the effect of fireworks, etc., to achieve enhanced anti-aging ability, enhanced mechanical strength, and extrusion strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

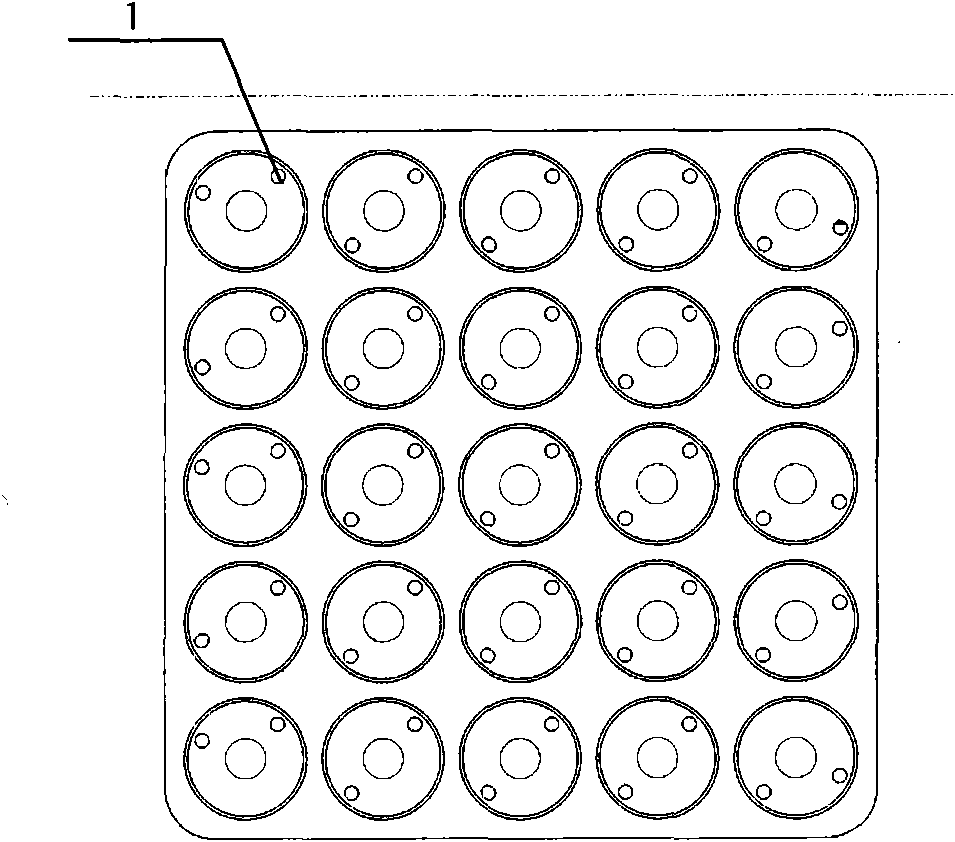

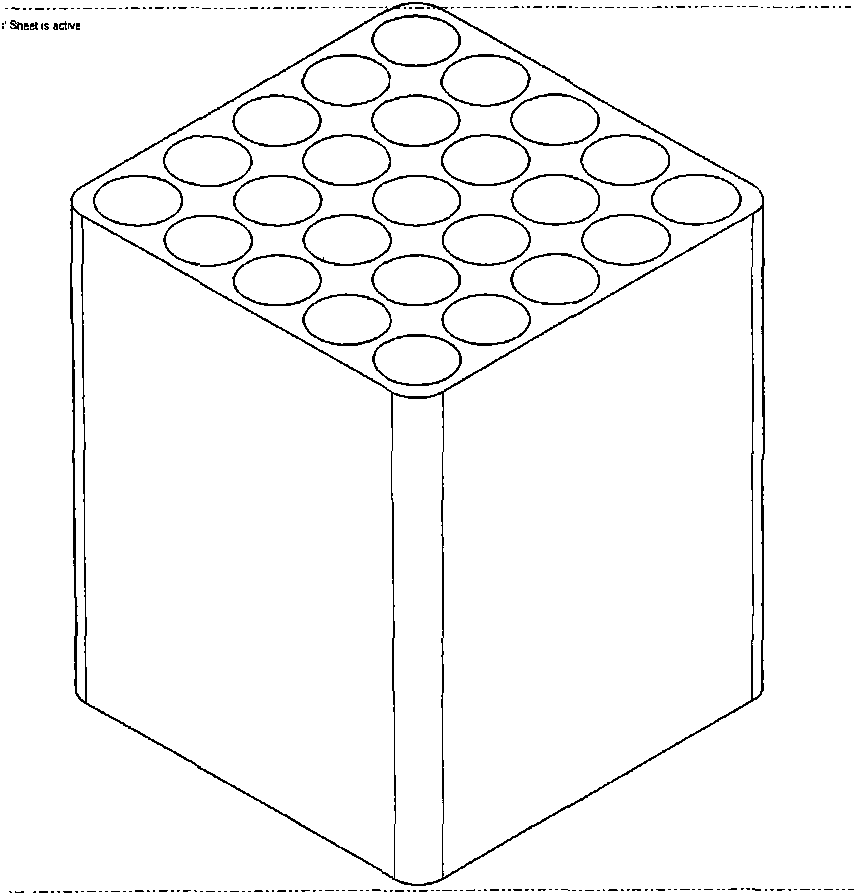

Image

Examples

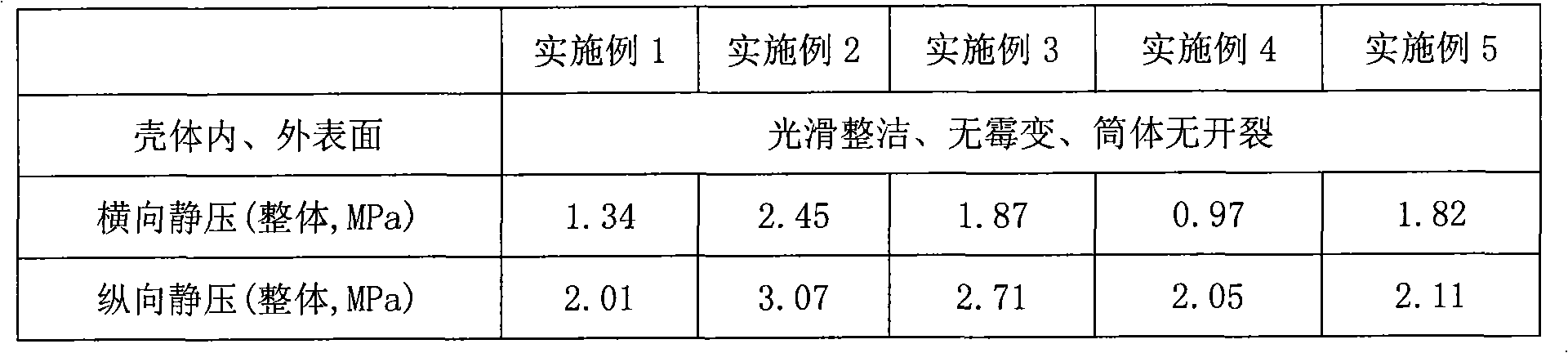

Embodiment 1

[0053] 1) Prepare materials according to the following proportions by weight (unit: kg)

[0054] Cornstarch 1.75

[0055] Vegetable fiber 1.75

[0056] Clay 5.25

[0057] Active agent 0.3

[0058] Stabilizer 0.2

[0059] Among them, the plant fiber is directly crushed waste paper to make waste paper fiber scraps, the width of waste paper fiber scraps is 0.02-0.15mm, and the length is ≤15mm; clay chooses talcum powder, and its particle size is 300-1500 mesh; active agent selection Aqueous silicone resin solution, its mass percentage concentration is 20%; Stabilizer selects cationic starch SH-P03 (cationic tapioca modified starch) for papermaking;

[0060] 2) Add water to the first mixing tank, heat and keep it at 100°C, add cornstarch and stabilizer quaternary ammonium cationic cornstarch under stirring state to carry out starch gelatinization, wherein the weight part of water and cornstarch The ratio is 2.5:1, the stirring rate is 65 rpm, stirring until the starch gelatin...

Embodiment 2

[0068] 1) Prepare materials according to the following proportions by weight (unit: kg)

[0069] Potato starch 1.5

[0070] plant fiber 2

[0071] clay 6

[0072] Active agent 0.2

[0073] Stabilizer 0.4

[0074] Among them, the plant fiber is made by crushing wheat straw stalks, the length and width of wheat straw shavings are 0.05-0.15mm, and the length is ≤15mm; the clay chooses double fly powder, and its particle size is 300-1500 mesh; the active agent chooses paraffin microemulsion, The solid content is 30%, and the pH value is 7-9; the stabilizer is quaternary ammonium cationic potato starch (cationic potato modified starch);

[0075] 2) Add water into the first and material tank, heat and keep it at 90°C, add potato starch and stabilizer quaternary ammonium cationic potato starch under stirring to carry out starch gelatinization, wherein, the weight part of water and potato starch The ratio is 3:1 and the stirring rate is 60 rpm, stirring until the starch gelatiniz...

Embodiment 3

[0083] 1) Prepare materials according to the following proportions by weight (unit: kg)

[0084] Tapioca starch 1.6

[0085] Vegetable fiber 1.85

[0086] Clay 5.5

[0087] Active agent 0.24

[0088] Stabilizer 0.25

[0089] Among them, the plant fiber is made by crushing soybean straw, the width of the soybean straw fiber is 0.05-0.15mm, and the length is ≤15mm; the clay is kaolin powder, and the particle size is 300-1500 mesh; the active agent is cationic fluororesin solution, The solid content is 25±1%, the specific gravity is 1.0-1.1, and the pH value is 3.5-5; the stabilizer is cationic tapioca modified starch;

[0090]2) Add water to the first mixing tank, heat and keep it at 100°C, add tapioca starch and stabilizer quaternary ammonium cationic tapioca starch under stirring state to carry out starch gelatinization, wherein, the weight part of water and tapioca starch The ratio is 2:1, the stirring rate is 65 rpm, stirring until the starch gelatinizes into a frozen s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com