Bent casing pipe non-uniform collapse strength simulation test method and device

A test method, non-uniform technology, applied in the direction of applying stable tension/compression to test material strength, etc., can solve problems such as lack of accuracy and reliability, failure to consider the impact of casing collapse strength, test data verification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

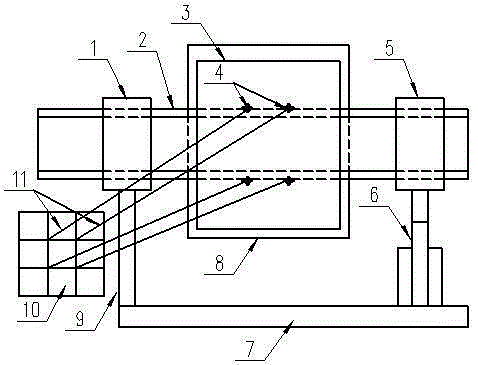

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The present invention utilizes the thrust bearing and the right fixture (the right fixture can reciprocate up and down under the action of the thrust bearing.) to apply an additional bending moment to the casing fixed by the left fixture and the bracket, so that the casing bends and produces a certain dogleg degree , using the front moving indenter and the rear moving indenter of the pressure testing machine to apply non-uniform loads to the curved casing, and at the same time record the casing strain under different external loads through the strain gauges and strain gauges on the outer wall of the casing, and draw based on the test data The relationship curve between non-uniform load and casing strain can be calculated to obtain the non-uniform collapse strength of the casing under the dogleg degree, and the non-uniform collapse strength of the casing under d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com