Preparation method of heavy metal solid waste curing agent

A technology for solid waste and solid waste, which is applied in the field of preparation of a solidifying agent for heavy metal solid waste, can solve the problems of poor solidification effect of heavy metals, inability of solid waste to be recycled, and harmless reduction in quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of heavy metal solid waste solidifying agent comprises the steps:

[0029] 1) Test block production, curing agent composition and weight percentage

[0030] Dead-burned magnesium oxide powder accounts for 30%; potassium dihydrogen phosphate accounts for 25%; borax accounts for 3%; fly ash accounts for 8%; heavy metal solid waste accounts for 19%, of which heavy metal accounts for 0.5% of the total curing agent After mixing with water, make a test block of 707mm×707mm×707mm;

[0031] The test block is used for testing after curing for 7 days at a temperature of 20°C and a relative humidity above 90%;

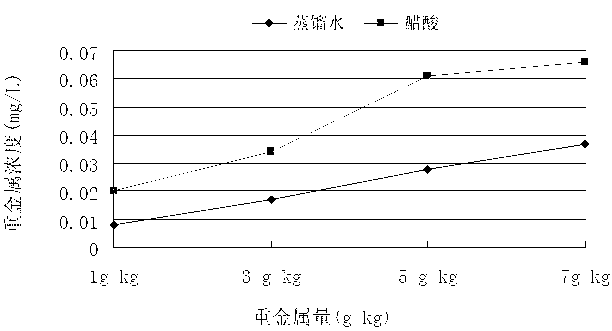

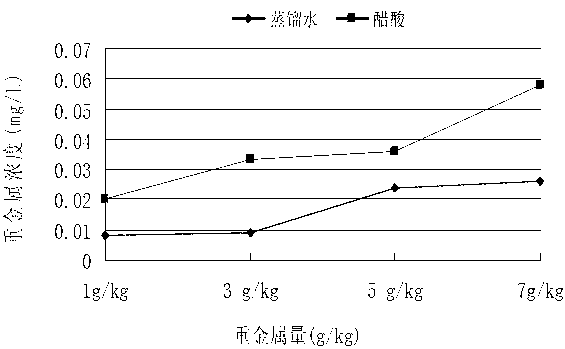

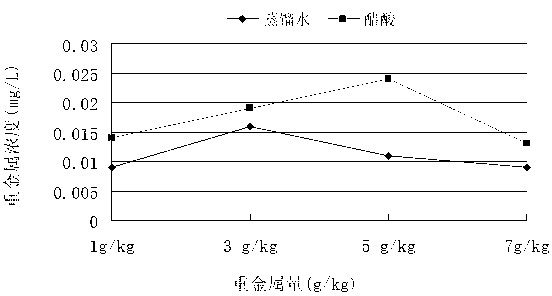

[0032] 2) Take the cured and crushed test piece and grind it finely, pass it through a 0.6 mm sieve for later use, mix 50 g of the finely ground powder with 1 000 mL of extraction solution, and stir for 18 hours with a dissolution tester; during the leaching process , take 2 different leaching conditions for horizontal comparison; these 2 leaching ...

Embodiment 2

[0044] Embodiment 2, the method comprises the steps:

[0045] 1) Test block production, curing agent composition and weight percentage

[0046]Dead-burned magnesium oxide powder accounted for 45%; potassium dihydrogen phosphate accounted for 30%; borax accounted for 5%; fly ash accounted for 10%; After mixing with water, make a test block of 707mm×707mm×707mm;

[0047] The test block is used for testing after curing for 8 days at a temperature of 20°C ± 3°C, a relative humidity of more than 90%;

[0048] 2) Take the cured and crushed test piece and grind it finely, pass it through a 0.6 mm sieve for later use, mix 50 g of the finely ground powder with 1 000 mL of extraction solution, and stir for 18 hours with a dissolution tester; during the leaching process , take 2 different leaching conditions for horizontal comparison; these 2 leaching conditions are: Condition 1, according to TCLP standard preparation of extraction agent: 5.7 mL of glacial acetic acid in 500 mL of dist...

Embodiment 3

[0060] Embodiment 3, the method comprises the steps:

[0061] 1) Test block production, curing agent composition and weight percentage

[0062] Dead-burned magnesia powder accounted for 35%; potassium dihydrogen phosphate accounted for 28%; borax accounted for 4%; fly ash accounted for 9%; After mixing with water, make a test block of 707mm×707mm×707mm;

[0063] The test block is used for testing after being cured for 28 days at a temperature of 17°C and a relative humidity above 90%;

[0064] 2) Take the cured and crushed test piece and grind it finely, pass it through a 0.6 mm sieve for later use, mix 50 g of the finely ground powder with 1 000 mL of extraction solution, and stir for 18 hours with a dissolution tester; during the leaching process , take 2 different leaching conditions for horizontal comparison; these 2 leaching conditions are: Condition 1, according to TCLP standard preparation of extraction agent: 5.7 mL of glacial acetic acid in 500 mL of distilled water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com