Valve state on-line monitoring system and working method thereof

A monitoring system and valve technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to establish parameter relationships, deviations, inability to identify and judge faulty valves, and achieve the effects of high reliability, compact structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

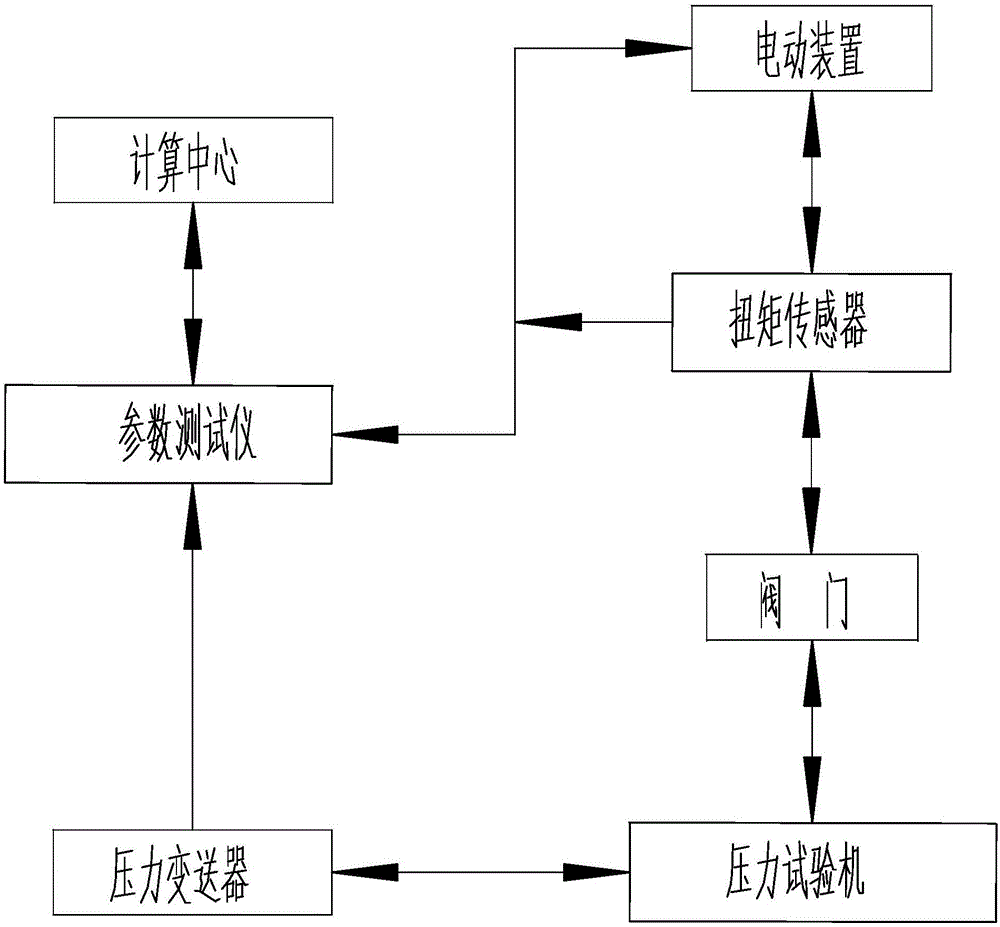

[0038] The present invention as Figure 1-3 As shown, including computing center, parameter tester, pressure transmitter, pressure testing machine, electric device and torque sensor;

[0039] The electric device is connected to the valve and used to drive the valve to open or close;

[0040] The torque sensor is connected between the electric device and the valve, and is used to collect the current torque of the valve;

[0041] The pressure testing machine is connected to the valve and used to apply external pressure to the valve;

[0042] The pressure transmitter is connected with the pressure testing machine, and is used to measure the current working pressure on the valve and convert it into a current signal;

[0043] The pressure transmitter, torque sensor, and electric device are all connected to the computing center through a parameter tester, and the parameter tester is used for mutual conversion of current signals and voltage signals.

[0044] The calculation center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com