Experimental device for comprehensive testing of marine pipeline mechanical properties

A comprehensive test and experimental device technology, applied in the direction of measuring devices, scientific instruments, strength characteristics, etc., can solve the problems of inability to carry out various experimental combinations, difficult to meet the sealing requirements, and unmatched experimental devices, so as to achieve diversification of experimental forms, Good sealing performance and diverse experimental objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

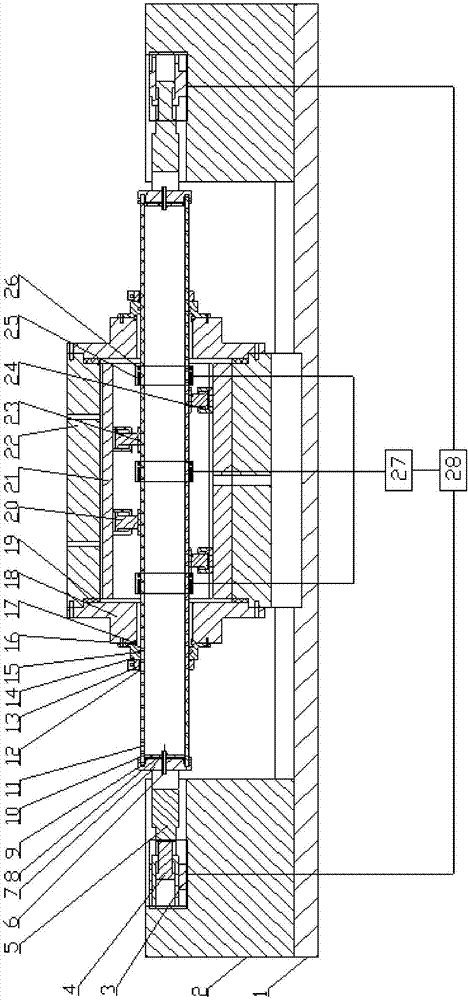

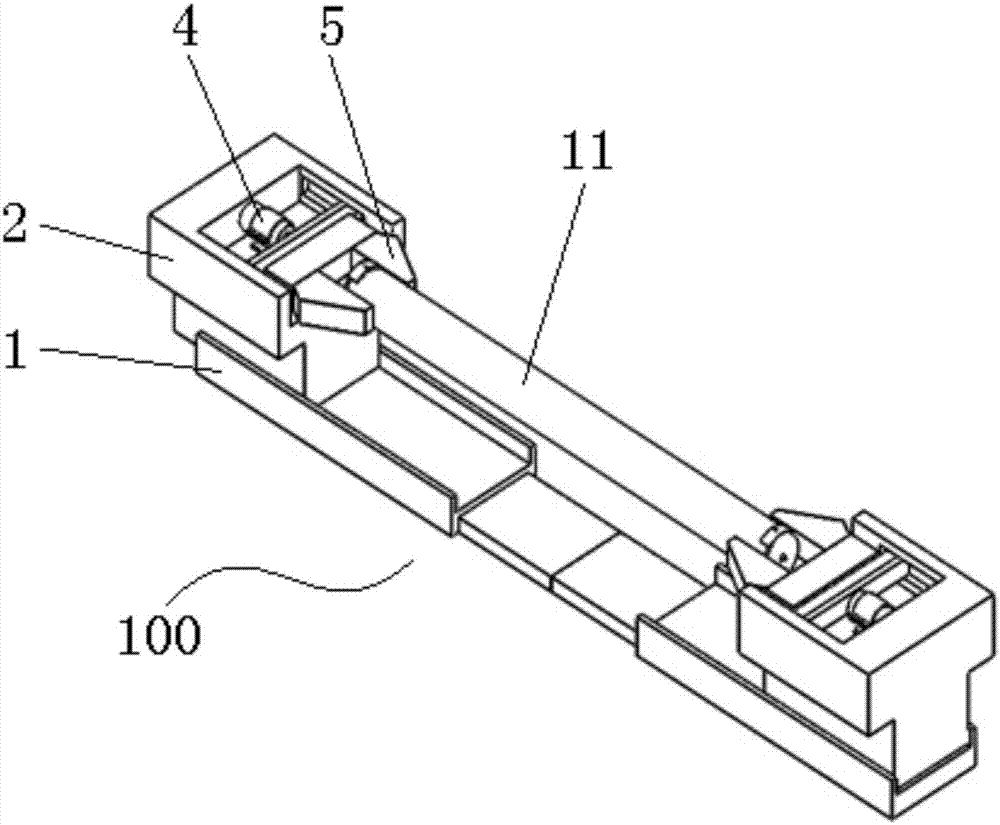

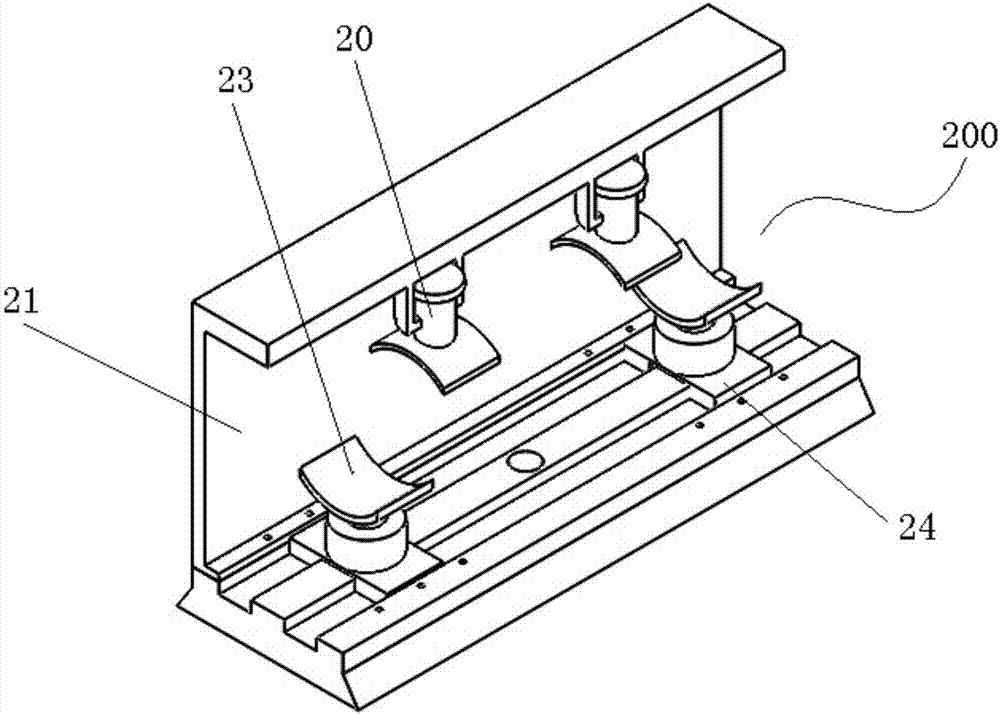

[0022] Such as Figure 1 to Figure 4 As shown, the marine pipeline mechanical performance comprehensive test experimental device provided by the present invention includes a tension and compression test device 100, a four-point bending test device 200, an external pressure test device 300, an internal pressure test device 400, a data acquisition and analysis device, and a hydraulic pump. Station 28 and channel base 1.

[0023] Such as figure 1 , figure 2 As shown, the tension-compression test device 100 includes two groups of tension-compression test assemblies relatively arranged on the trough-shaped base 1, and each group of tension-compression tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com