Cement compression resistance clamp for compression testing machine and usage method of clamp

A pressure test and cement technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems affecting the compressive performance of cement mortar and the inability to test the compressive strength of cement mortar specimens, etc. Achieve the effects of simple structure, simple compressive strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

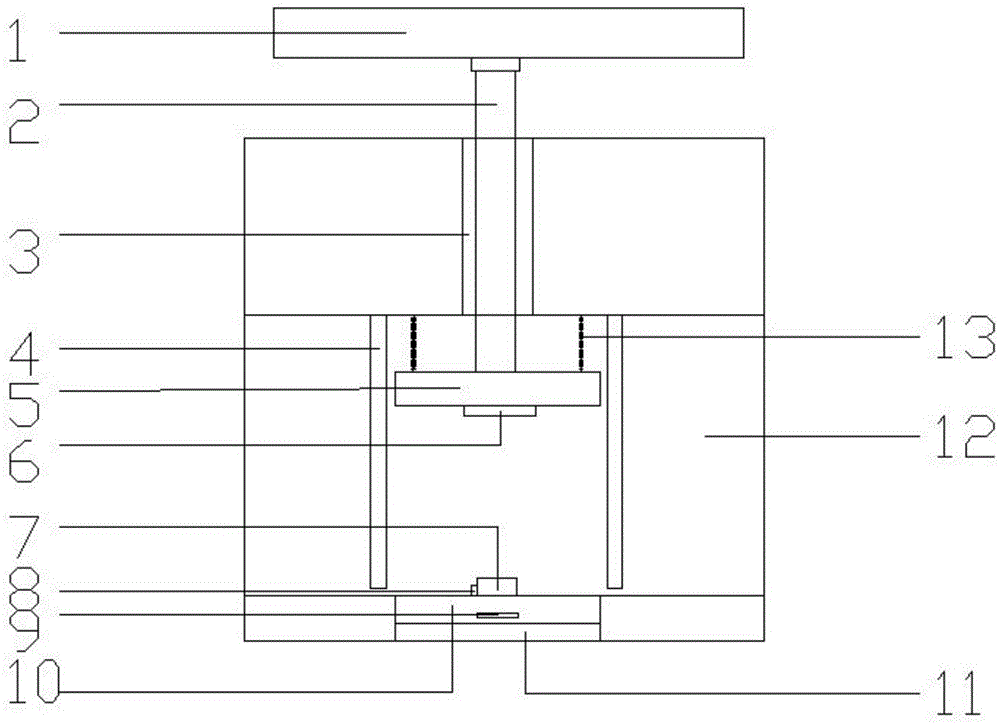

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

[0024] refer to figure 1 , the cement anti-compression fixture of pressure testing machine of the present invention comprises housing 12, telescoping rod 2, bearing plate 1, slide block 5, specimen position calibration post 8, indenter 6 and some springs 13; Housing 12 One side of the housing 12 is open, the top of the housing 12 is provided with a through hole 3, the upper end of the telescopic rod 2 is fixed on the pressure bearing plate 1, the lower end of the telescopic rod 2 is inserted into the housing 12 through the through hole 3, and the slider The upper part of the 5 is connected with the lower end of the telescopic rod 2, the pressure head 6 is fixed on the bottom of the slider 5, one end of the spring 13 is connected with the inner surface of the top of the housing 12, and the other end of the spring 13 is fixed on the upper part of the slider 5, The press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com