High-speed dynamic compression testing device

A dynamic compression, high-speed technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the sample cannot be loaded at a constant speed and the strain rate changes greatly, and achieve low manufacturing cost and simple device structure , to avoid the effect of damaging the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

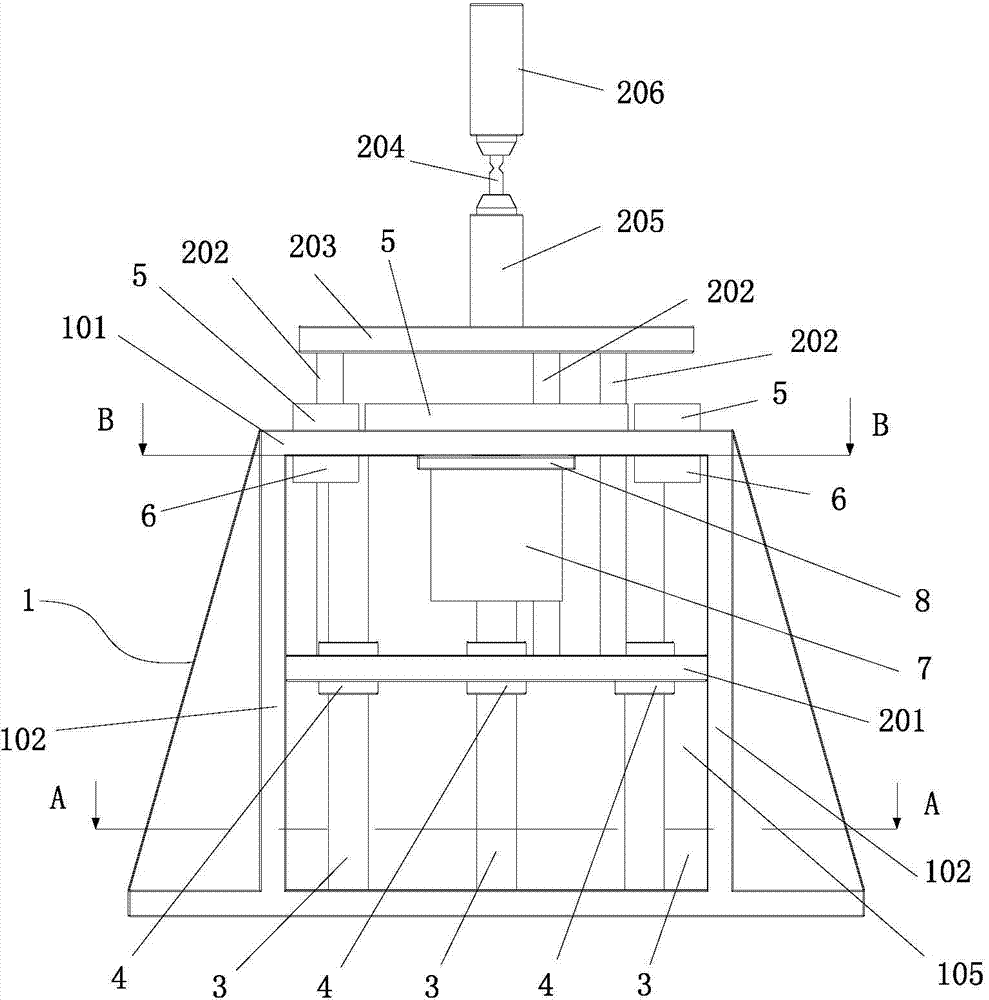

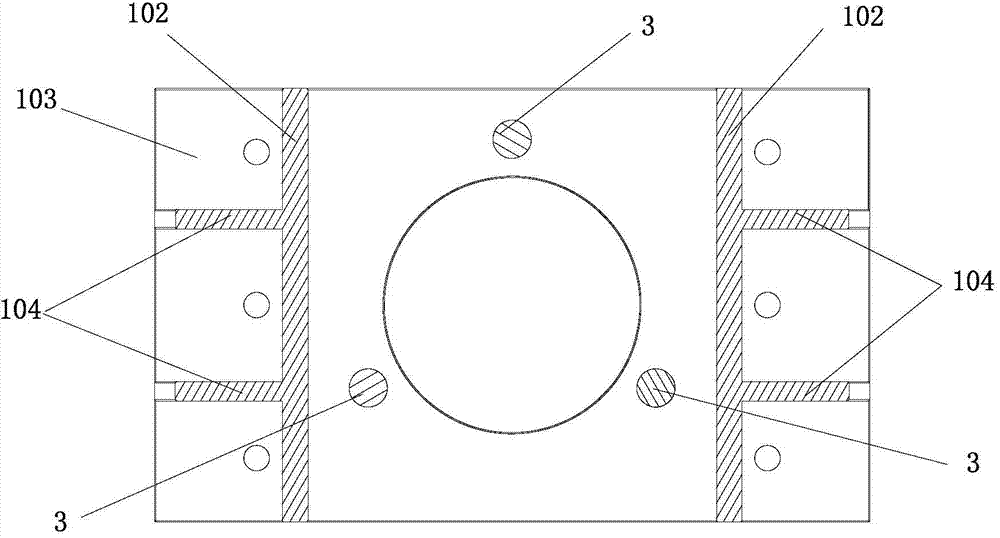

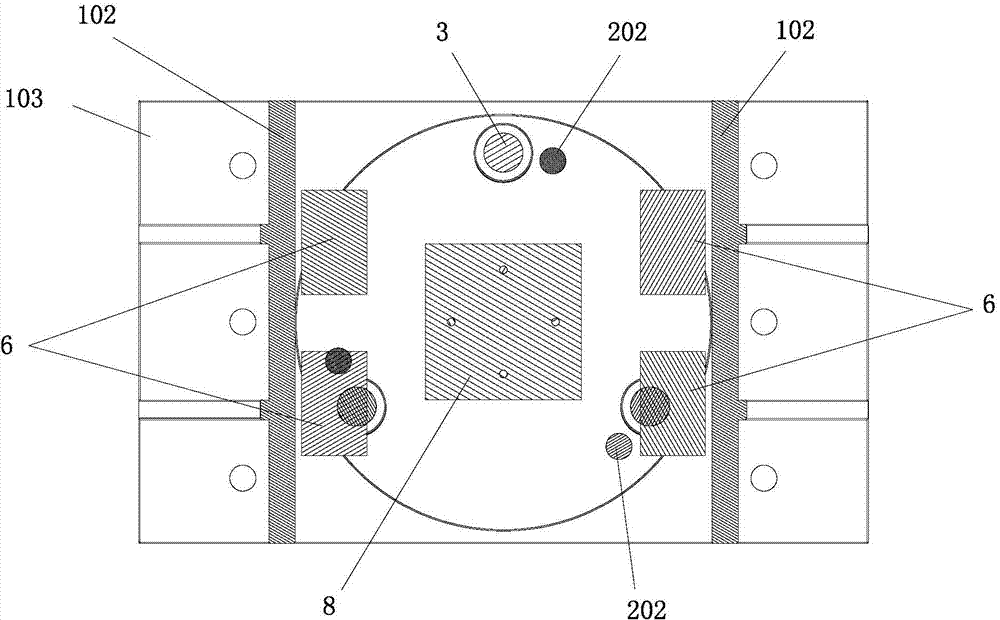

[0028] as attached Figures 1~7 As shown, a high-speed dynamic compression test device is used for a high-speed tensile testing machine. The device includes a base 1 for installing a test specimen 7 and a loading mechanism 2 for compressing the specimen 7. The loading mechanism 2. It includes a pressure plate 201 for compressing the test piece 7 and a connecting rod 202 fixedly connected to the pressure plate 201 at one end. The base 1 has a cavity 105 for accommodating the test piece 7 and the pressure plate 201 and a mounting plate for installing the test piece 7 101, one end of the connecting rod 202 is located in the cavity 105, and the other end extends through the mounting plate 101 to the outside of the cavity 105, and the connecting rod 202 is slidably arranged with the mounting plate 101, and the loading mechanism 2 also includes a surface with The other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com