Biaxial tensile compression testing device under ultrahigh temperature complex load

A biaxial stretching, complex load technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc. The requirements of water cooling technology, the effect of versatility and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

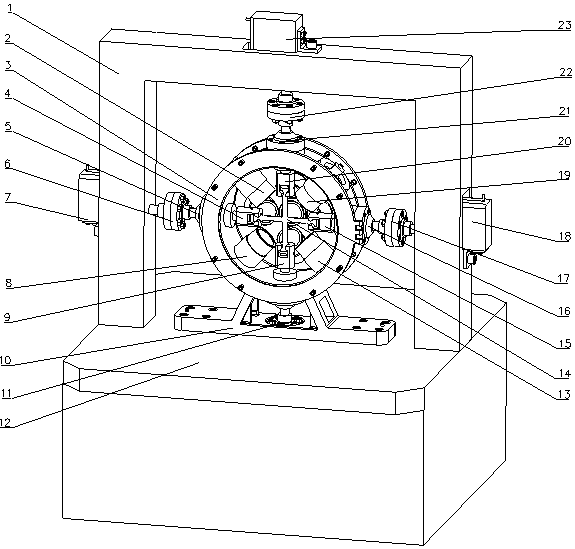

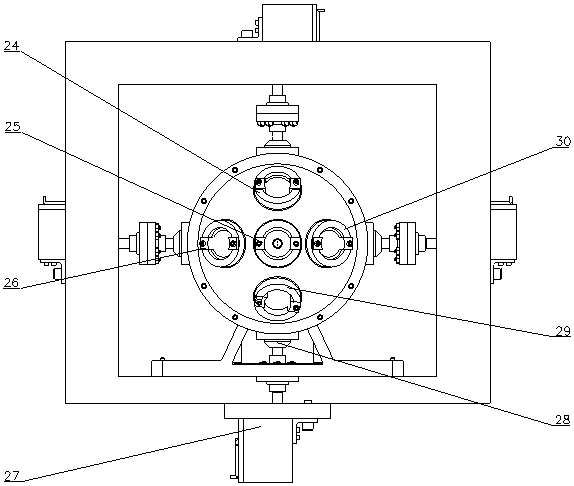

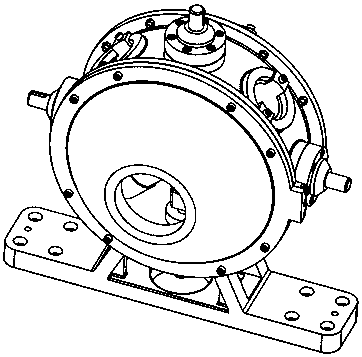

[0027] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0028] see Figure 1 to Figure 5 As shown, the ultra-high temperature complex load biaxial tensile compression test device of the present invention includes a biaxial tensile / compressive load driving unit, a bidirectional signal detection and control unit, an ultra-high temperature loading unit, and a clamping unit. The biaxial tensile The compression load drive unit is connected to the gantry column 1 through bolts. The bidirectional signal detection and control unit is composed of tension and pressure sensors I~IV6, 11, 17, and 22, which are rigidly connected with the high-temperature chamber 3 by threads. The ultra-high-temperature loading unit is rigidly fixed in the high-temperature chamber 3, and the clamping unit is clamped on the main axis of the clamp by expansion sleeves I~IV5, 16, 21, and 28. The air-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com