Control method of primary air fan of circulating fluidized bed boiler

A technology of circulating fluidized bed and control method, applied in the field of linkage control of primary fan frequency converter + outlet baffle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

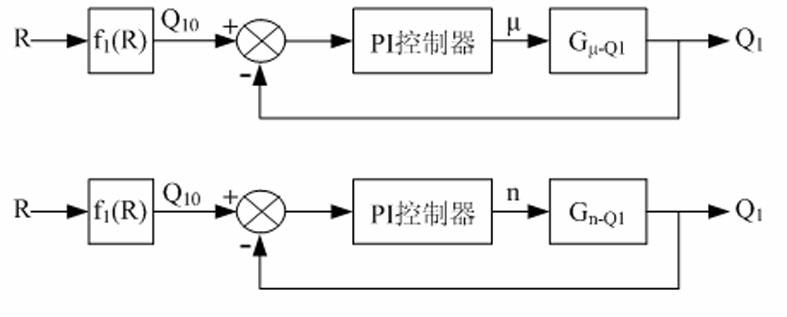

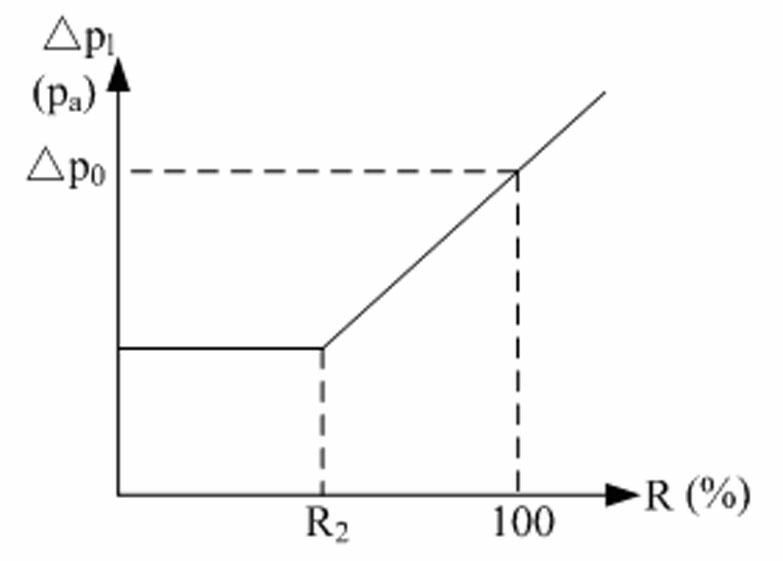

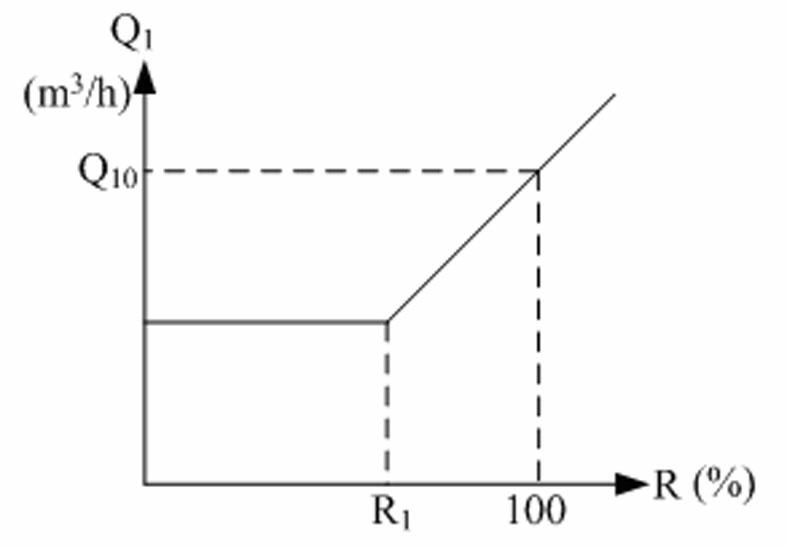

[0029] (1) According to figure 2 , image 3 The indicated bed pressure drop △p l and primary air volume Q 1 The operating characteristics of the bed pressure drop determined by the boiler load rate R and primary air volume .

[0030] (2) Bed pressure drop and primary fan outlet baffle opening and primary air volume Related, can be described as: (1)

[0031] In formula (1), is the bed pressure drop resistance characteristic coefficient, which is determined by the design flow point; It is the resistance coefficient related to the opening of the primary fan outlet baffle, which is a correlation and determined by the resistance characteristic test of the baffle opening. bed pressure drop , primary air volume and coefficient is known, the corresponding baffle opening can be determined by formula (1) .

[0032] (3) Total pressure of primary fan It can be obtained by calculating the resistance of the flue gas system:

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com