In-situ method for obtaining rock parameters

A technology of rock parameters and in-situ testing, applied in the direction of applying stable tension/pressure to test material strength, sampling, sampling devices, etc., can solve the problems of difficulty in obtaining in-situ rock mass parameters and bulky instruments, and increase reliability Operational performance, complete functions, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through the accompanying drawings and embodiments.

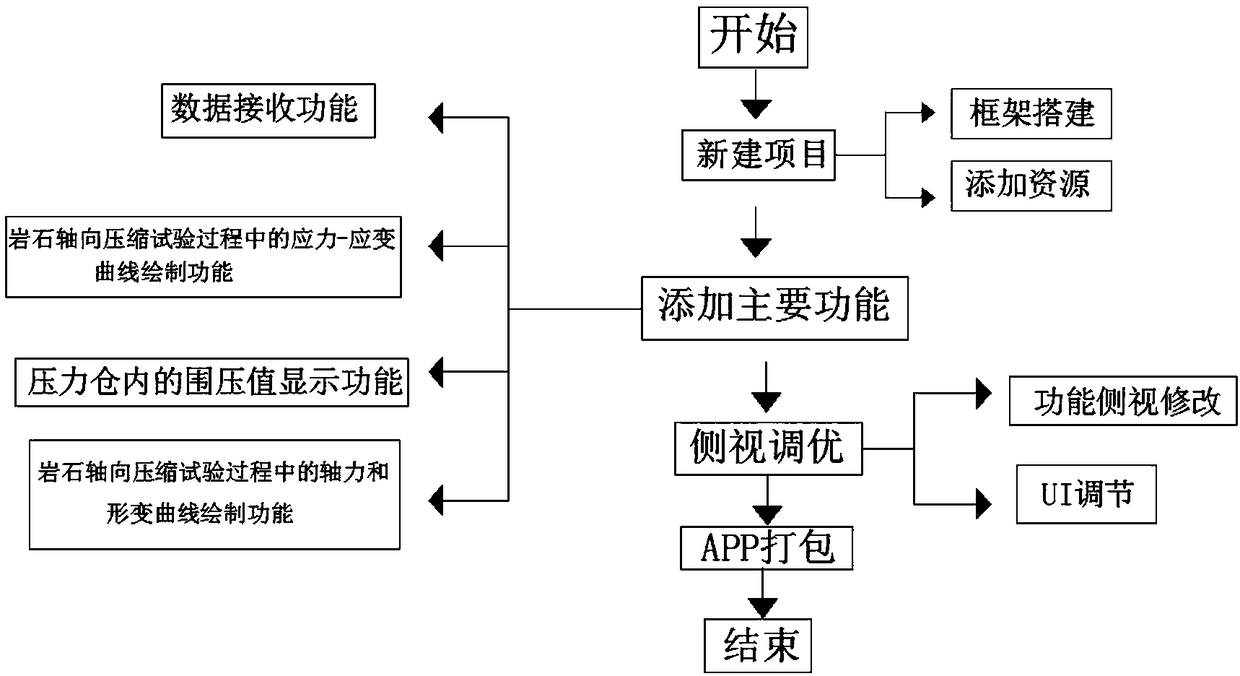

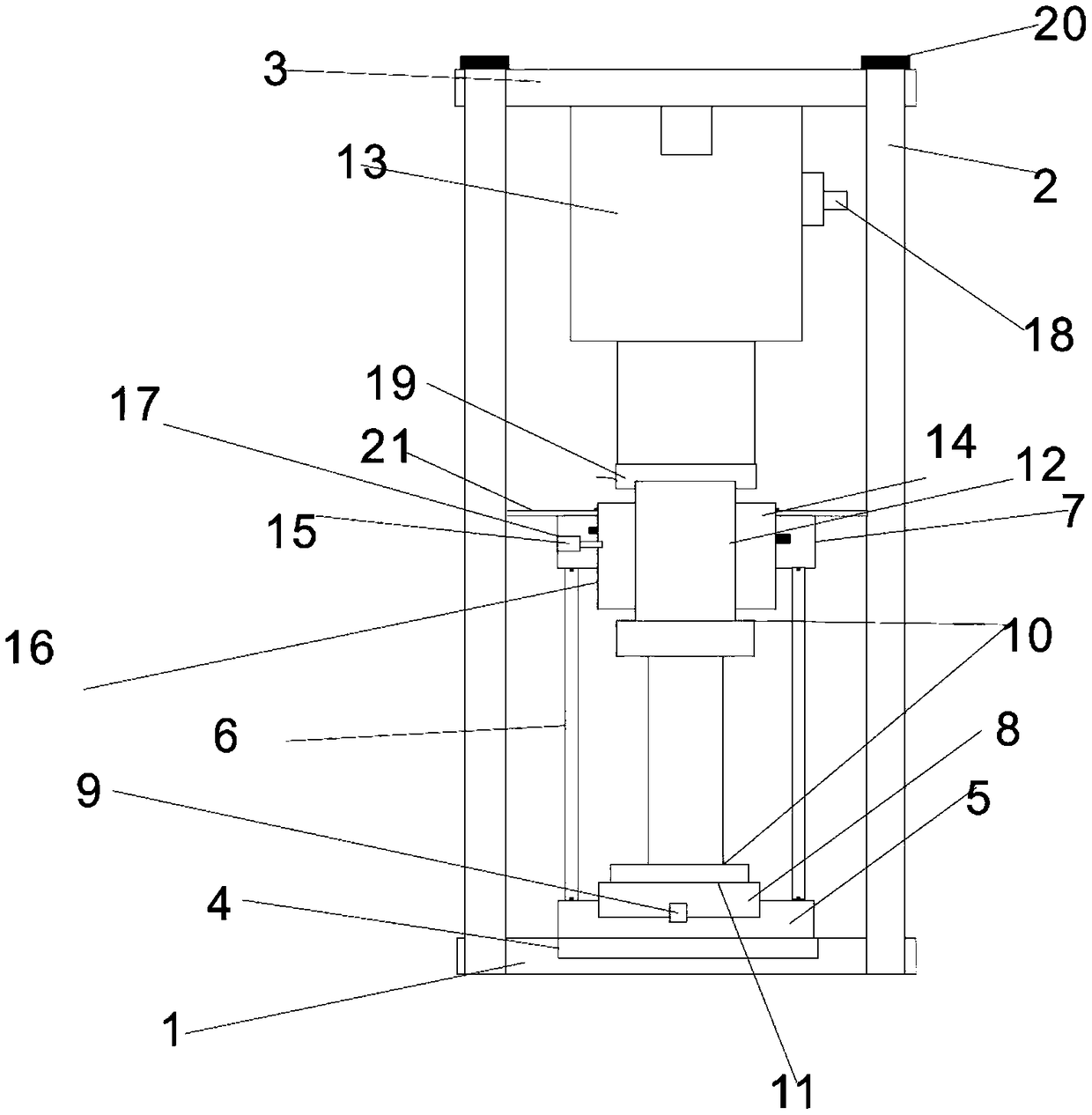

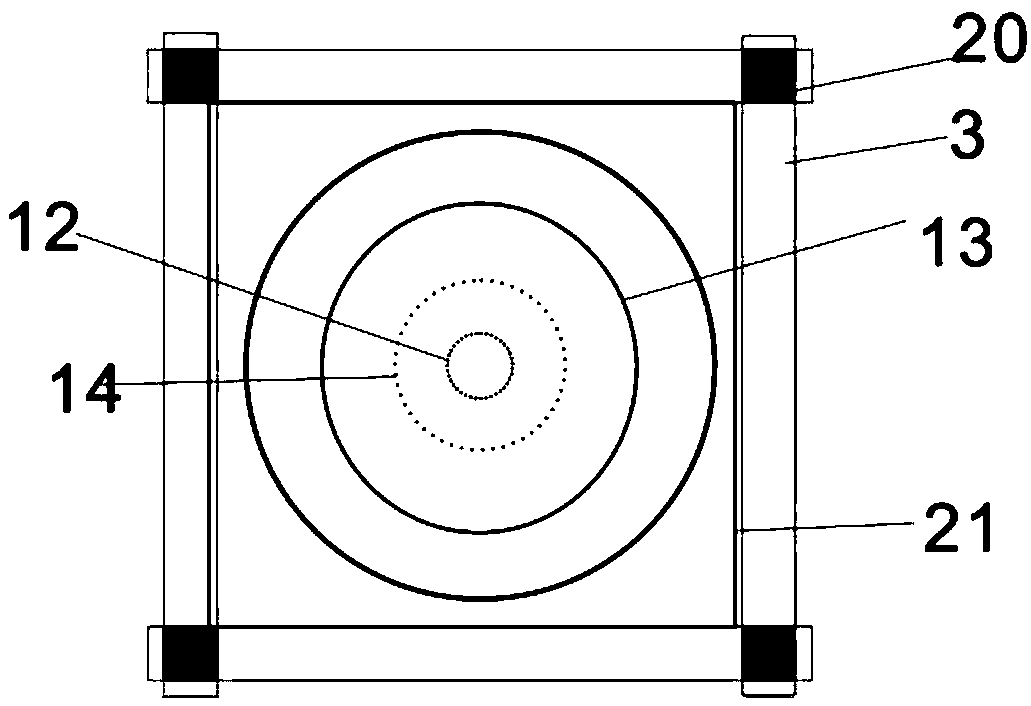

[0034] The embodiment of the present invention provides an in-situ test method for obtaining rock parameters, such as Figure 1-5 As shown, it includes a test host, a pressure control system and a sensor measurement system. The test host includes a lower pedestal (1), a column (2), an upper top plate (3) and a locking nut (20), and the pressure chamber Placed on the lower seat groove (4) to increase stability, the pressure chamber is composed of a pressure chamber base (5) an acrylic glass cylinder (6) and a pressure chamber top plate (7). Connect the steel pedestal (8) and the pressure chamber base (5) with connecting bolts (9). During the test, place the core on the lower steel cylinder (10) and the lower steel cylinder (10). Install the axial pressure sensor (11) to measure the axial pressure. The axial pressure exerted by the hydraulic jack (13) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com