Low-strain quality detection measuring tool and testing method thereof

A low-strain, measuring tool technology, which is used in the testing of infrastructure, construction, infrastructure engineering, etc., can solve the problems of high-frequency wave interference at the top of the pile, different signal waves, and inconsistent signal curves, so as to reduce the impact of diffusion and reduce artificial error, the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

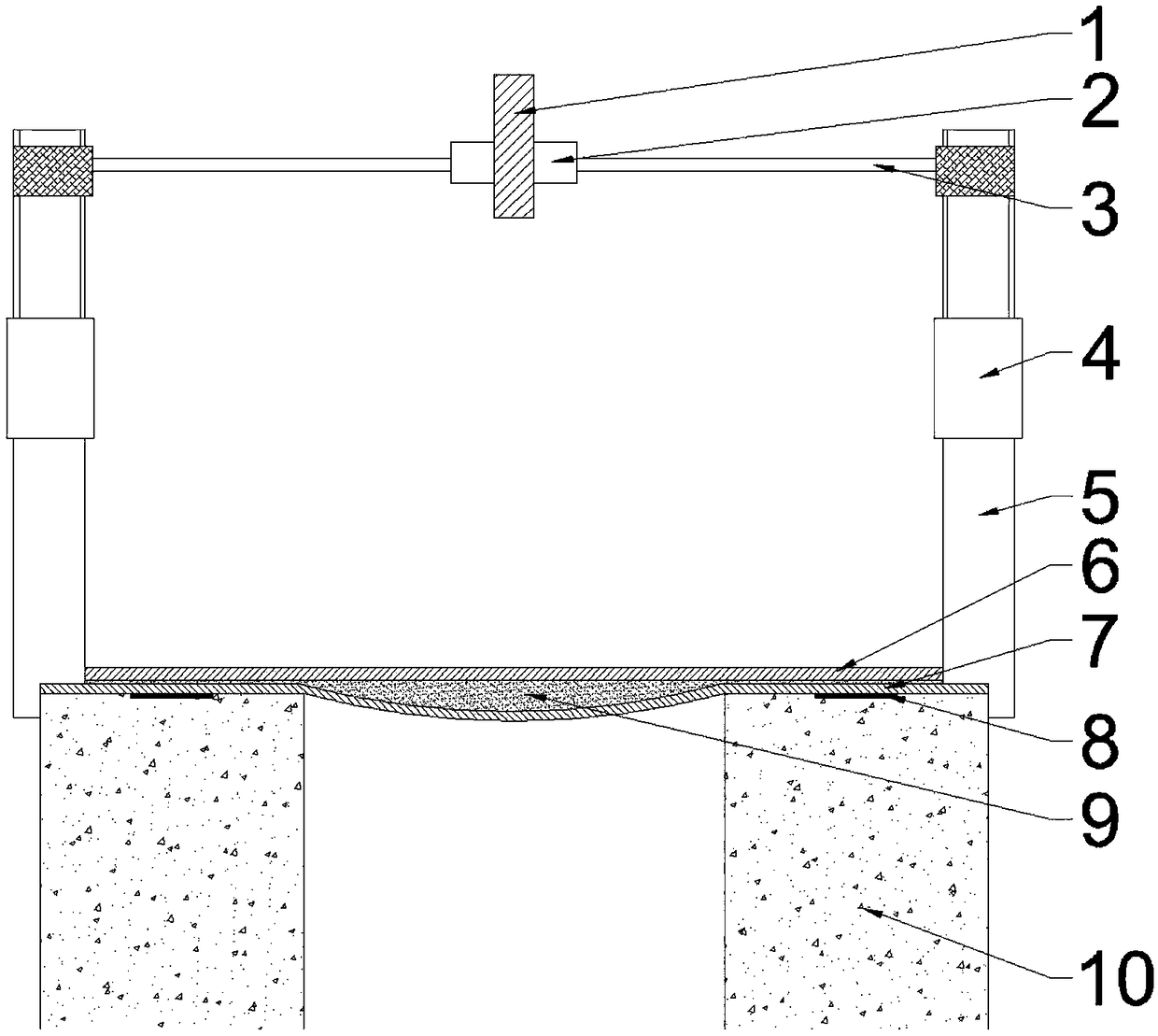

[0023] see figure 1 A schematic diagram of a preferred embodiment of a low-strain quality detection measuring tool, in this embodiment, the measuring tool includes an impact disc 7 and a positioning bracket, wherein the impact disc 7 includes a lower concave disc body and an outer edge of the lower concave disc body The connected annular disk surface, the annular disk surface and the lower concave disk body are integrally formed, and the arc surface of the longitudinal section of the lower concave disk body corresponds to an included angle of 25°, so as to balance and absorb the influence of the stress wave propagation on the horizontal plane when the vibrating hammer falls , and has the smallest effect on the stress wave in the vertical phase a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com