A (100) oriented diamond n-i-p junction diode and its preparation method

An n-i-p, single crystal diamond technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of low quality of i-type layer and high ohmic contact resistivity of n-type layer, etc., to improve the ohmic contact of electrodes traits, reduced spread effects, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

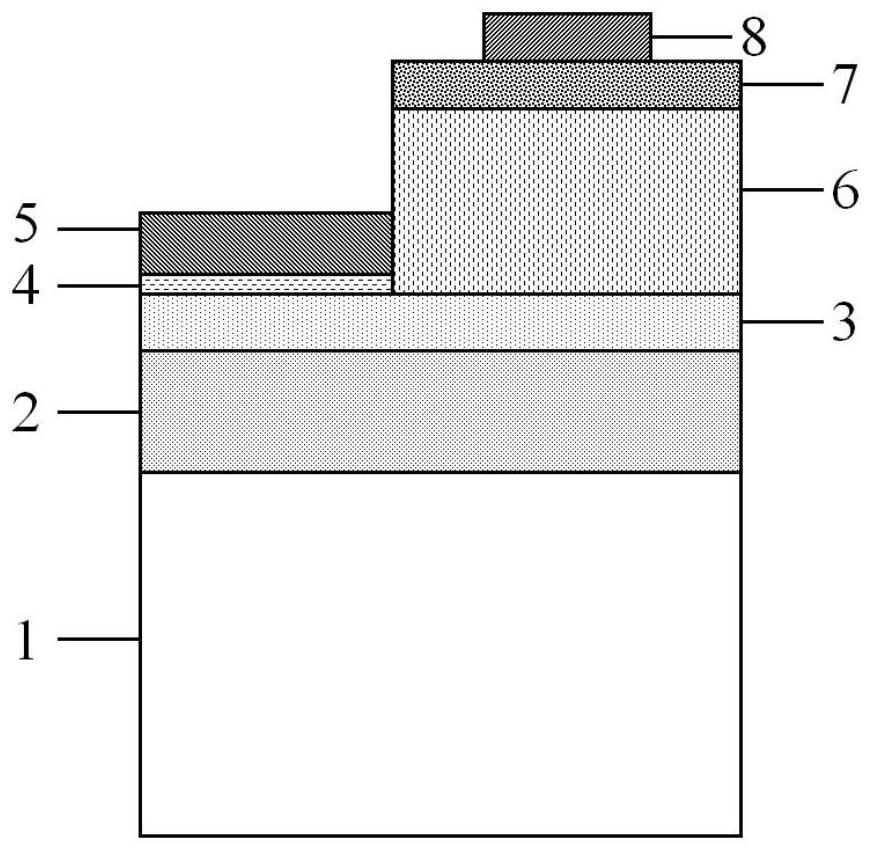

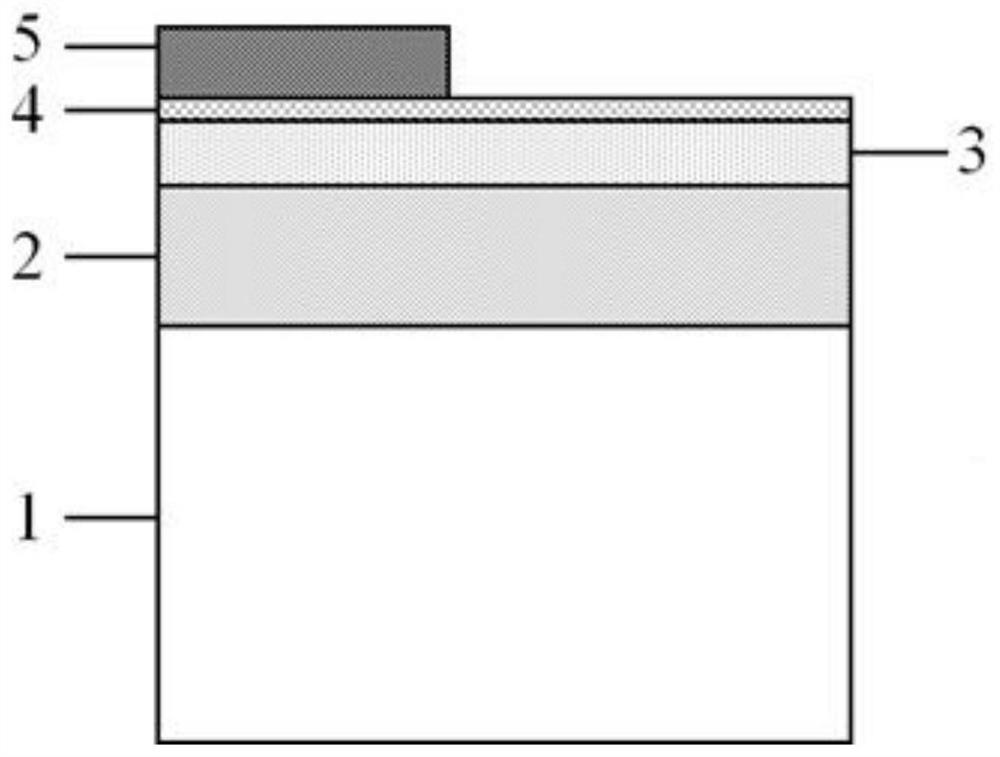

[0041] Such as figure 1 , Ohmic electrical pole rectangular diamond N-I-P diode, the single crystal diamond substrate 1 is high temperature high pressure synthesis single crystal diamond, size is 3 × 3 × 0.3mm 3 . The MPCVD method is used to grow 20 μm n diamond 2 on the surface of the substrate. The growth conditions are: the air pressure is 100 torr, the gas flow is 500 sccm, CH 4 / H2 = 0.05%, pH 3 / CH 4 = 10,000 ppm, substrate temperature is 950 ° C, doping concentration is 10 19 cm -3 . After the growth is over, the n-type diamond 2 is reduced to 10 μm with a polishing polishing machine, and the surface roughness is 1 nm. The MPCVD method is used to grow a layer of N-type diamond thin layer 3 on N-type diamond 2, and the growth conditions are: 100 Torr, gas flow rate of 500 sccm, CH 4 / H 2 = 0.05%, pH 3 / CH 4 = 5000 ppm, the substrate temperature is 900 ° C, and the growth thickness is 10 nm. After the growth, the sample was placed in sulfuric acid and nitric acid 1: 1 mix...

Embodiment 2

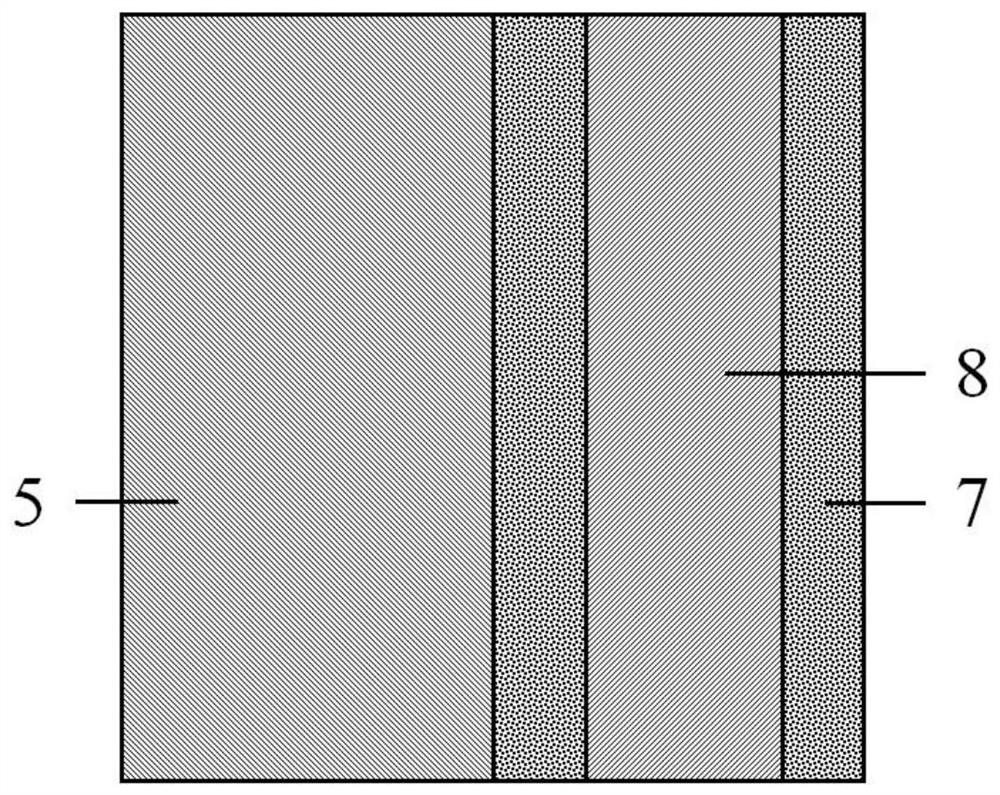

[0043] Such as Figure 4 , Ohmic electrical extremely circular diamond N-I-P diode, the single crystal diamond substrate 1 is high temperature high pressure synthesis single crystal diamond, size of 3 × 3 × 0.3mm 3 . The MPCVD method was used in the surface of the substrate to grow 15 μm n diamond 2, and the growth conditions were: the gas pressure of 100 torr, the gas flow was 500 sccm, CH 4 / H 2 = 0.05%, pH 3 / CH 4 = 10,000 ppm, substrate temperature is 950 ° C, doping concentration is 10 19 cm -3 . After the growth is over, the n-type diamond 2 is reduced to 5 μm with a polishing polishing machine, and the surface roughness is 0.5 nm. The MPCVD method is used to grow a layer of N-type diamond thin layer 3 on N-type diamond 2, and the growth conditions are: 100 Torr, gas flow rate of 500 sccm, CH 4 / H 2 = 0.05%, pH 3 / CH 4 = 100000 ppm, the substrate temperature is 900 ° C, and the growth thickness is 20 nm. After the growth is over, the sample is treated with ultraviolet ozo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com