Coaxial fluidized bed reaction system and reaction method for producing ethylene, propylene and aromatics by converting methanol and/or dimethyl ether

A technology of fluidized bed reaction and dimethyl ether, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, physical/chemical process catalysts, etc., can solve the problems of low yields of ethylene, propylene and aromatics, and achieve Effects of reducing diffusion effects, promoting contact, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

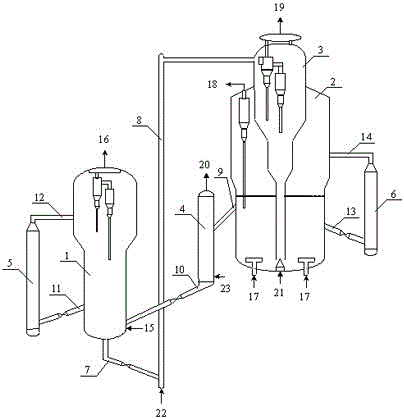

[0051] use as figure 1 device shown. The diameter of the reaction section of the reactor is 1.5 meters, and its height accounts for 80% of the total height of the reactor. The ratio of the diameter of the dilute phase section to the diameter of the reaction section is 2:1, and its height accounts for 15% of the total height of the reactor. The height of the external heat extractor of the reactor accounts for 85% of the height of the reactor. The height of the external heat receiver of the regenerator accounts for 70% of the height of the regenerator.

[0052] The reaction conditions of the reactor are: the temperature is 480° C., the reaction pressure in gauge pressure is 0.2 MPa, the weight space velocity is 2 (g / h) / g catalyst, and the mass ratio of the catalyst circulation amount to the raw material feed amount is 12 : 1, the catalyst density of the reaction zone in the reactor is 100 kg / m 3 , The average superficial gas velocity is 0.2 m / s. The regenerator temperature w...

Embodiment 2

[0057] use as figure 1 device shown. The diameter of the reaction section of the reactor is 5 meters, and its height accounts for 60% of the total height of the reactor. The ratio of the diameter of the dilute phase section to the diameter of the reaction section is 1.1:1, and its height accounts for 35% of the total height of the reactor. The height of the external heat extractor of the reactor accounts for 95% of the height of the reactor. The height of the external heat receiver of the regenerator accounts for 30% of the height of the regenerator.

[0058] The reaction condition of reactor is: temperature is 400 ℃, and gauge reaction pressure is 0.5 MPa, and weight space velocity is 10 (gram / hour) / gram catalyst, and the mass ratio of catalyst circulation amount and feedstock amount is 3 : 1, the catalyst density of the reaction zone in the reactor is 90 kg / m 3 , The average superficial gas velocity is 0.17 m / s. The temperature of the regenerator was 680°C. The content ...

Embodiment 3

[0063] The device of Example 1 was used.

[0064] The reaction condition of reactor is: temperature is 550 ℃, and with gauge pressure gauge reaction pressure is 0 MPa, and weight space velocity is 10 (gram / hour) / gram catalyst, and the mass ratio of catalyst circulation amount and raw material feeding amount is 30 : 1, the catalyst density of the reaction zone in the reactor is 50 kg / m 3 , with an average superficial air velocity of 1 m / s. The temperature of the regenerator was 580°C. The content of char on the regenerated catalyst is 0.09% by weight based on the mass percentage of the catalyst. Using methanol as a raw material, the water content is 0.01% by weight. The height of the external heat extractor of the reactor accounts for 30% of the height of the reactor. The height of the external heat receiver of the regenerator accounts for 60% of the height of the regenerator.

[0065] The stripping medium is water vapor. The lifting medium is N 2 . The regeneration mediu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com