Method for determining strain-induced martensite phase transformation kinetics curve

A technology of strain induction and martensitic phase, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of limited resources and difficult implementation of synchrotron radiation and neutron diffraction experimental devices, and achieve saving of measurement costs, The effect of high speed and improved measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through specific examples.

[0038] In the following examples, the metal materials containing metastable austenite phase are by weight percentage, and the alloying elements include 0.010-0.080% of C, ≤2.00% of Mn, ≤0.035% of P, ≤0.020% of S, ≤0.75% of Si, 8.00-10.50% Ni, 18.00-20.00% Cr, ≤0.10% N, and the balance is Fe.

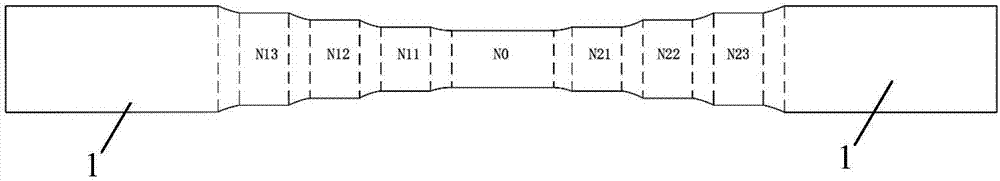

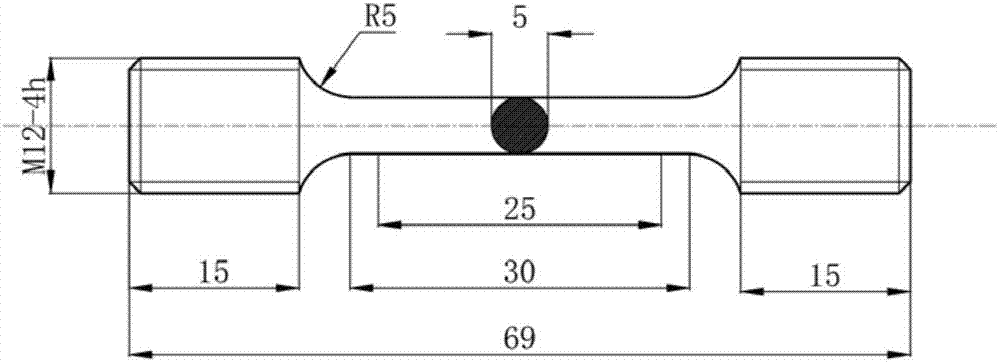

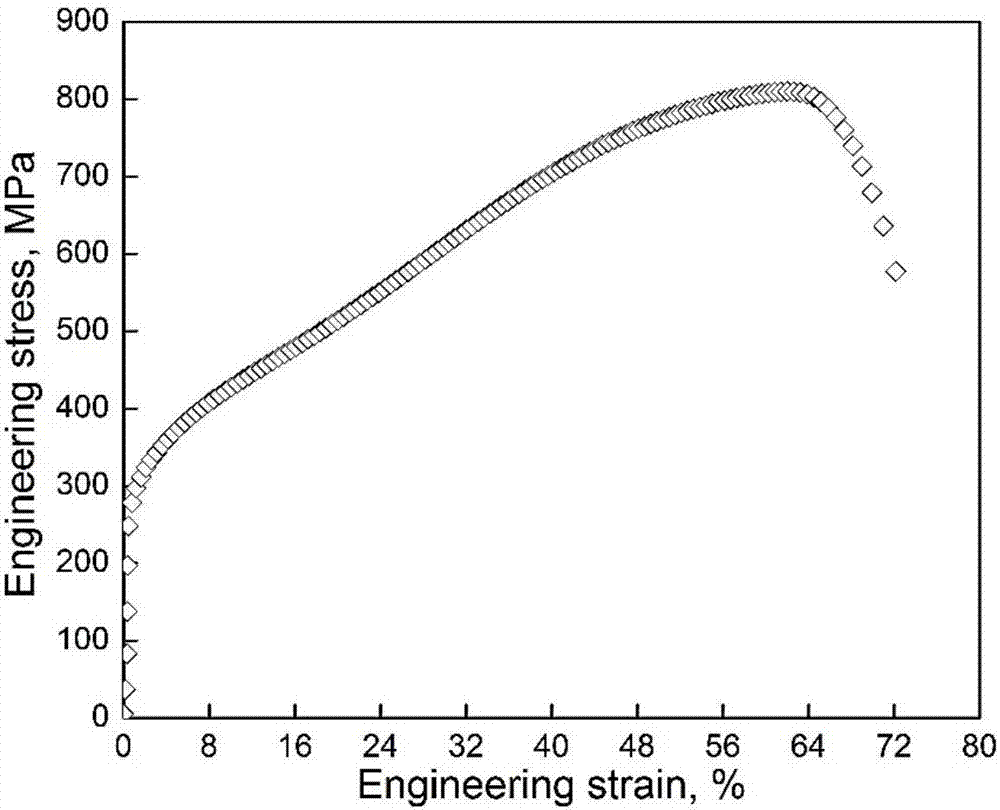

[0039]S1. Metal materials containing metastable austenite phase shall be tested according to GB / T228.1-2010 "Metal Materials Tensile Test Part 1: Room Temperature Test Method" or GB / T13239-2006 "Metal Materials Low Temperature Tensile Test Method" made as figure 2 The standard tensile specimen shown at room temperature is 6 x 10 -4 the s -1 The stress-strain curve is obtained by carrying out a tensile test at a strain rate of 0. The stress-strain curve includes a stress-strain part in the plastic deformation stage and a stress-strain part in the elastic deformation stage.

[0040] S2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com