Independent wheel suspension

A suspension device, independent wheel technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of tire wear, loss of tire lateral force potential, etc., to achieve reduced tire wear, low cost of angle measurement, accurate numerical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

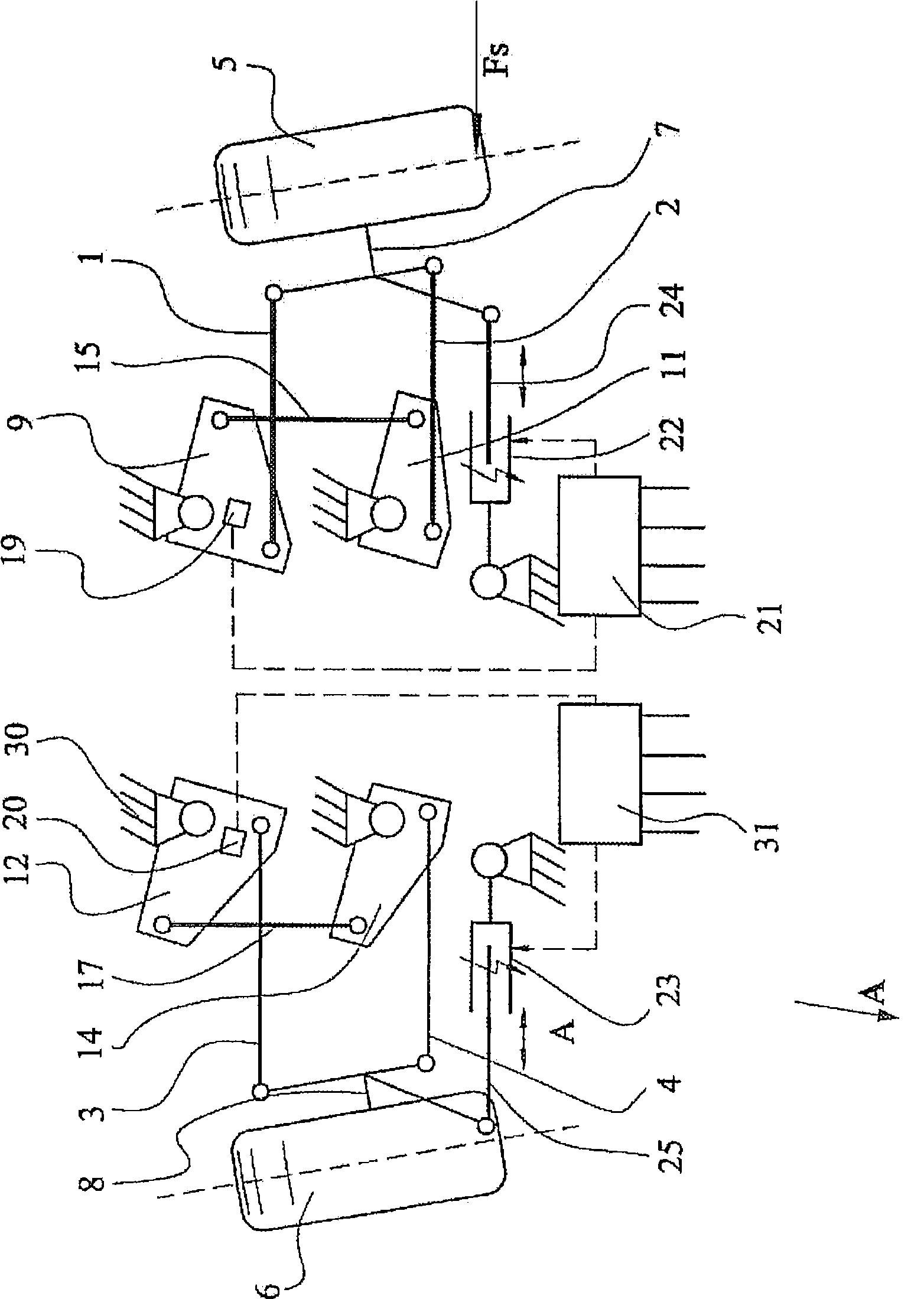

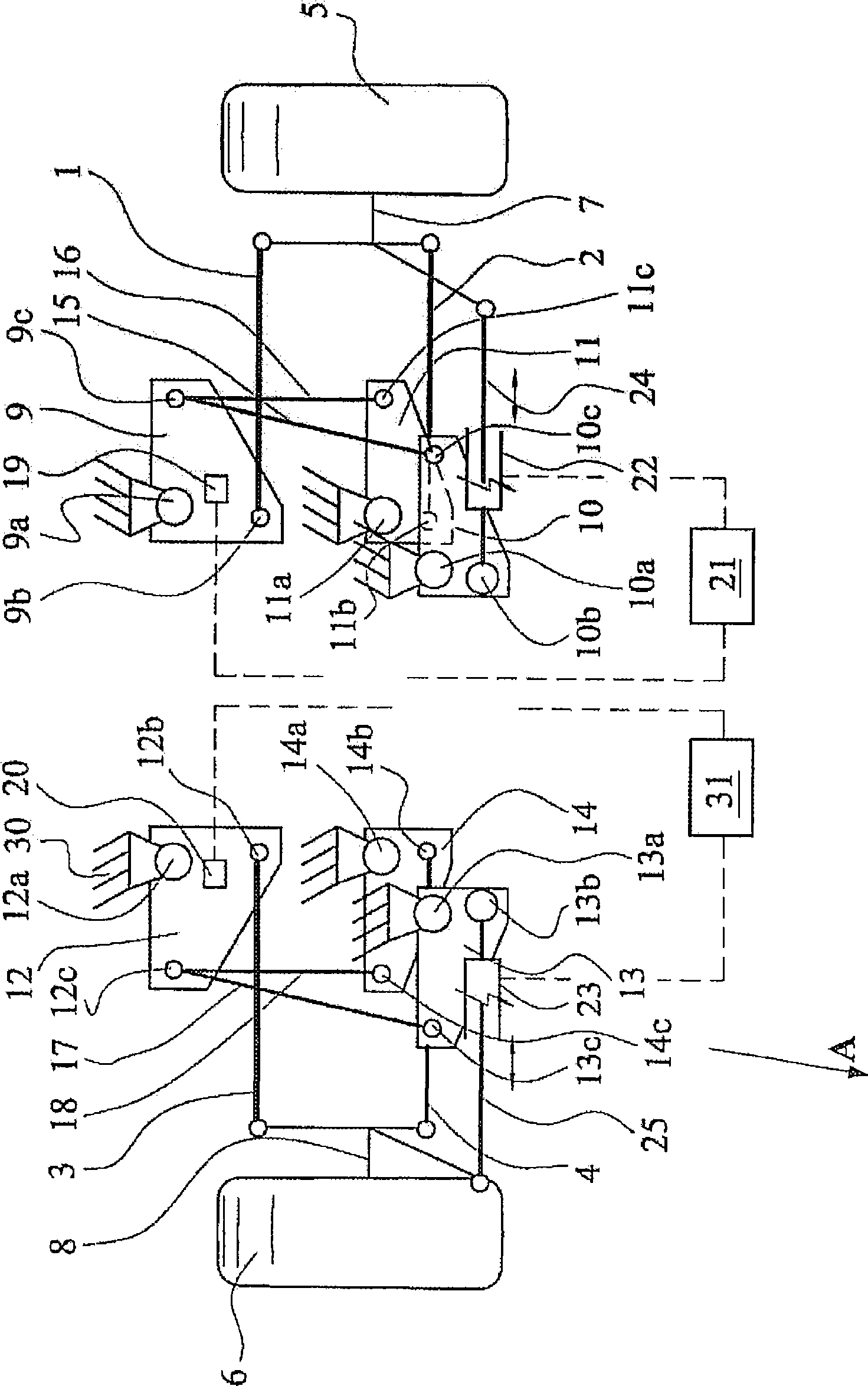

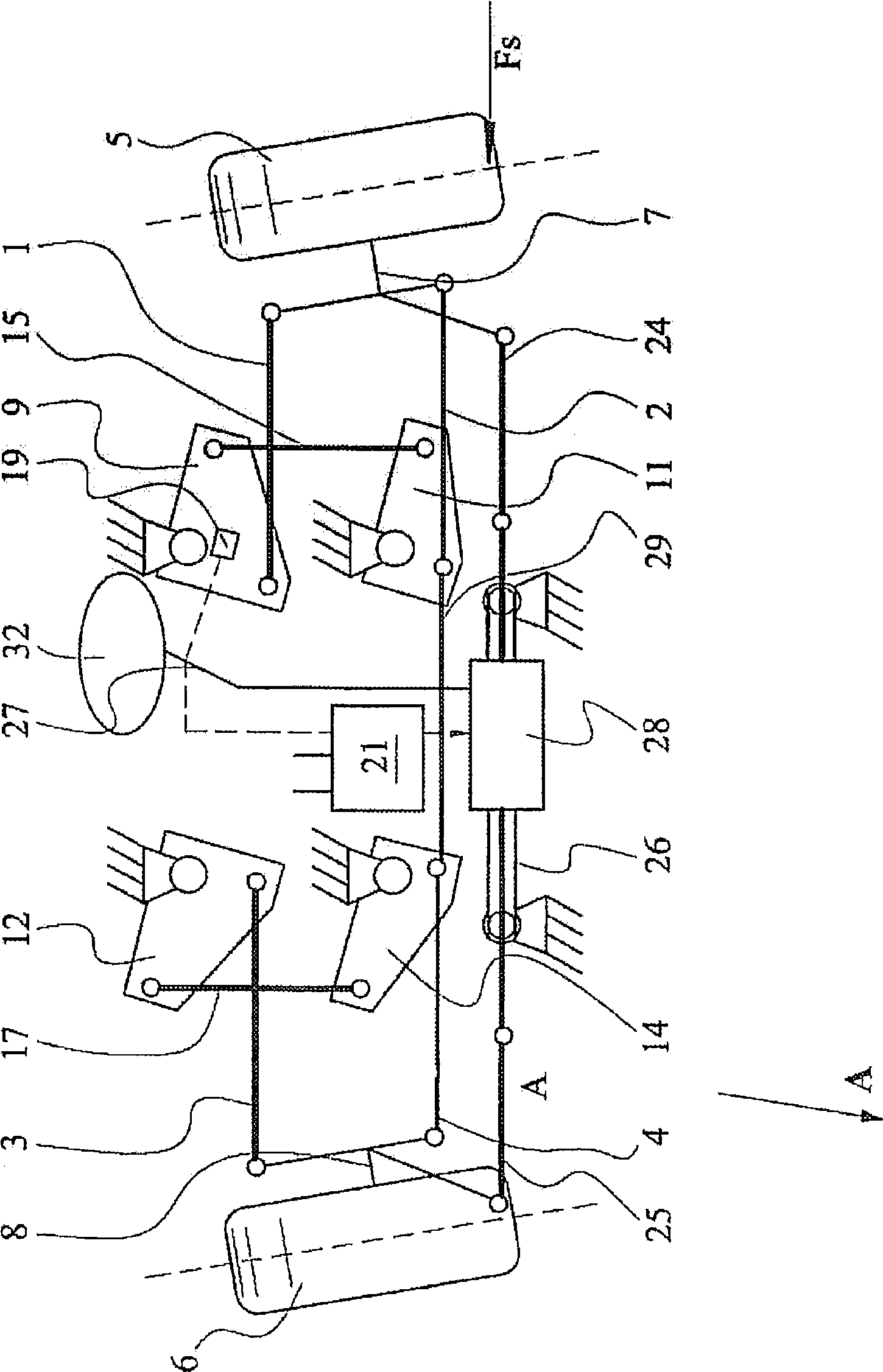

[0038] figure 1 A simplified first embodiment of the independent wheel suspension according to the invention is schematically shown, with the vehicle moving towards the observer. In the illustration, the wheel suspension is deflected due to a left turn. This means that the vehicle wheels 5 , 6 have an inclination relative to the vertical, which occurs, for example, when cornering. The steerable car wheels 5 and 6 are involved here. The independent wheel suspension has two guide rods 1 , 2 or 3 , 4 on each side with respect to the direction of travel indicated by the arrow “A”. Car wheel 5 is contained on the wheel support 7, and vehicle wheel 6 is contained on the wheel support 8. The two wheel carriers 7 or 8 are connected to the differential gear 9 , 11 or 12 , 14 via guide rods 1 , 2 or 3 , 4 respectively. The articulated connection between the vehicle wheels 5 , 6 and the differential 9 , 11 or 12 , 14 allows the deflection of the vehicle wheels 5 , 6 to be transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com