Nondestructive flaw detection device for metal wire/pipe

A metal wire, non-destructive flaw detection technology, applied in the direction of material magnetic variables, etc., can solve the problem of the change of the induced magnetic field signal parameters, etc., and achieve the effect of low measurement cost, simple measurement method and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

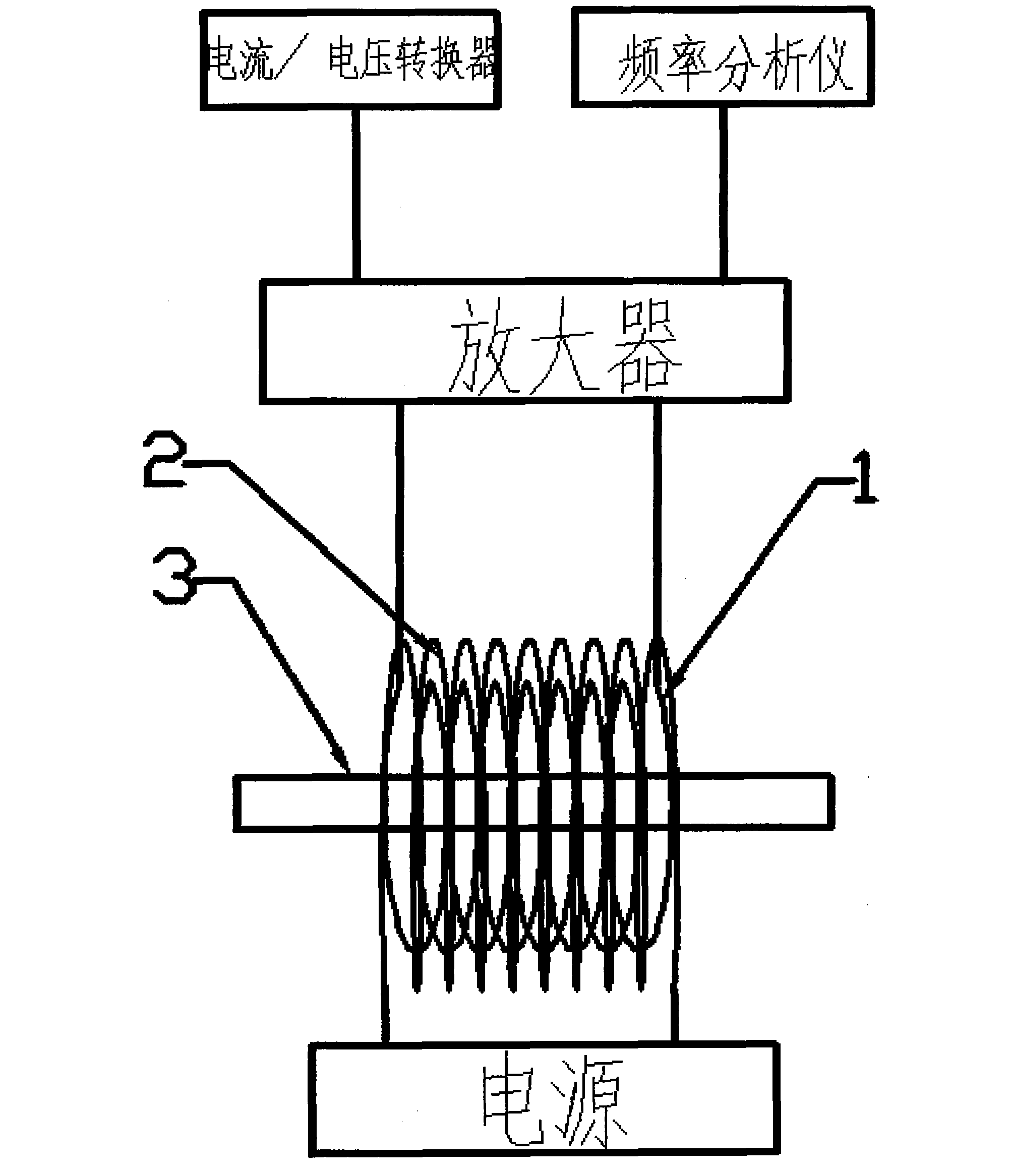

[0013] The structure and method of the invention are explained in detail below in conjunction with the accompanying drawings, as figure 1 In order to invent the structural schematic diagram of the non-destructive testing device, as shown in the figure, the metal wire / pipe non-destructive testing device of the present invention includes a measurement coil 1 and a magnetic field coil 2 nested in each other. The magnetic field coil is connected to a power supply and forms a changing electromagnetic field inside. The amplifier connects the measuring coil and sends the measuring signal to the frequency analyzer and the current / voltage converter respectively.

[0014] During the measurement process, the metal wire 3 to be tested moves longitudinally along the measuring coil and the magnetic field coil, respectively measures the signal parameter changes at the defective and non-defective positions when entering the measuring coil, and determines the defect position by comparing the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com