Device for measuring small clearance between end faces of mechanical products

A technology of mechanical products and measuring devices, applied in the direction of measuring devices, instruments, etc., can solve the problems of not being suitable for measuring small gaps on end faces, large measurement errors, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

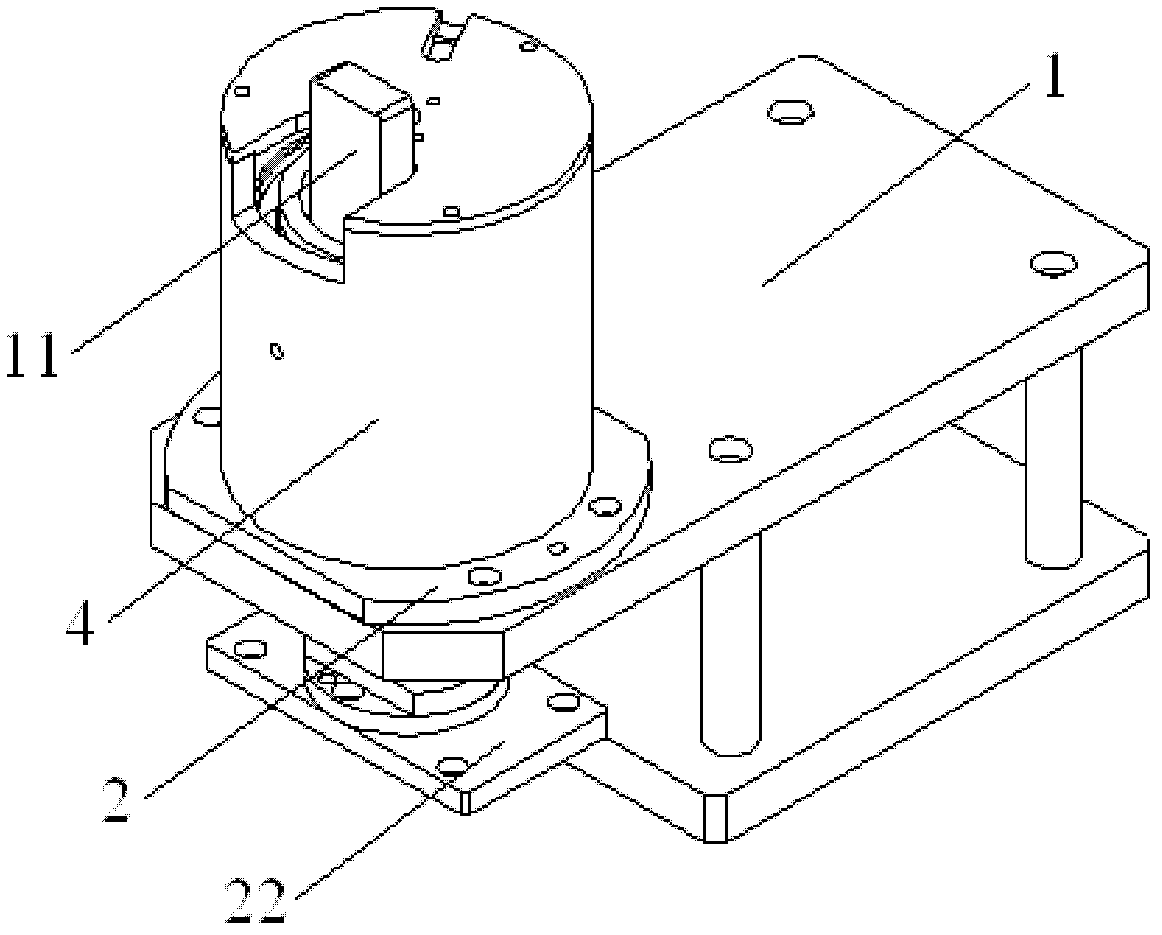

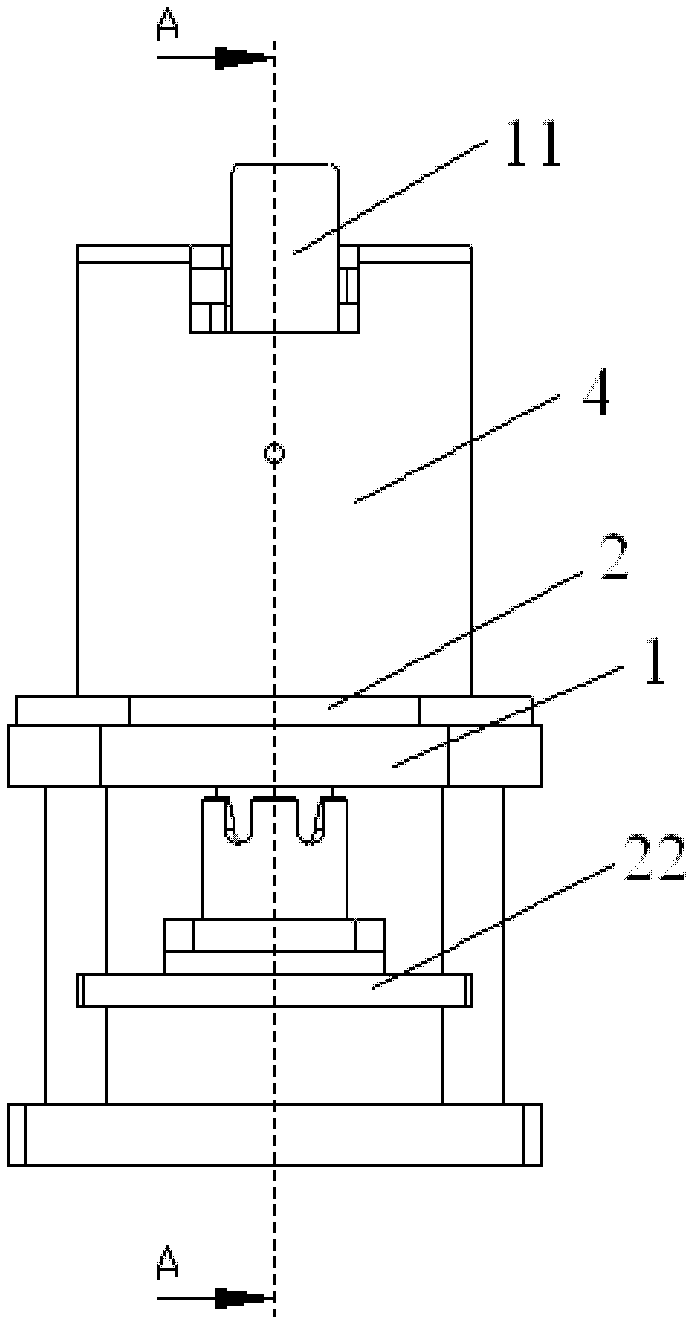

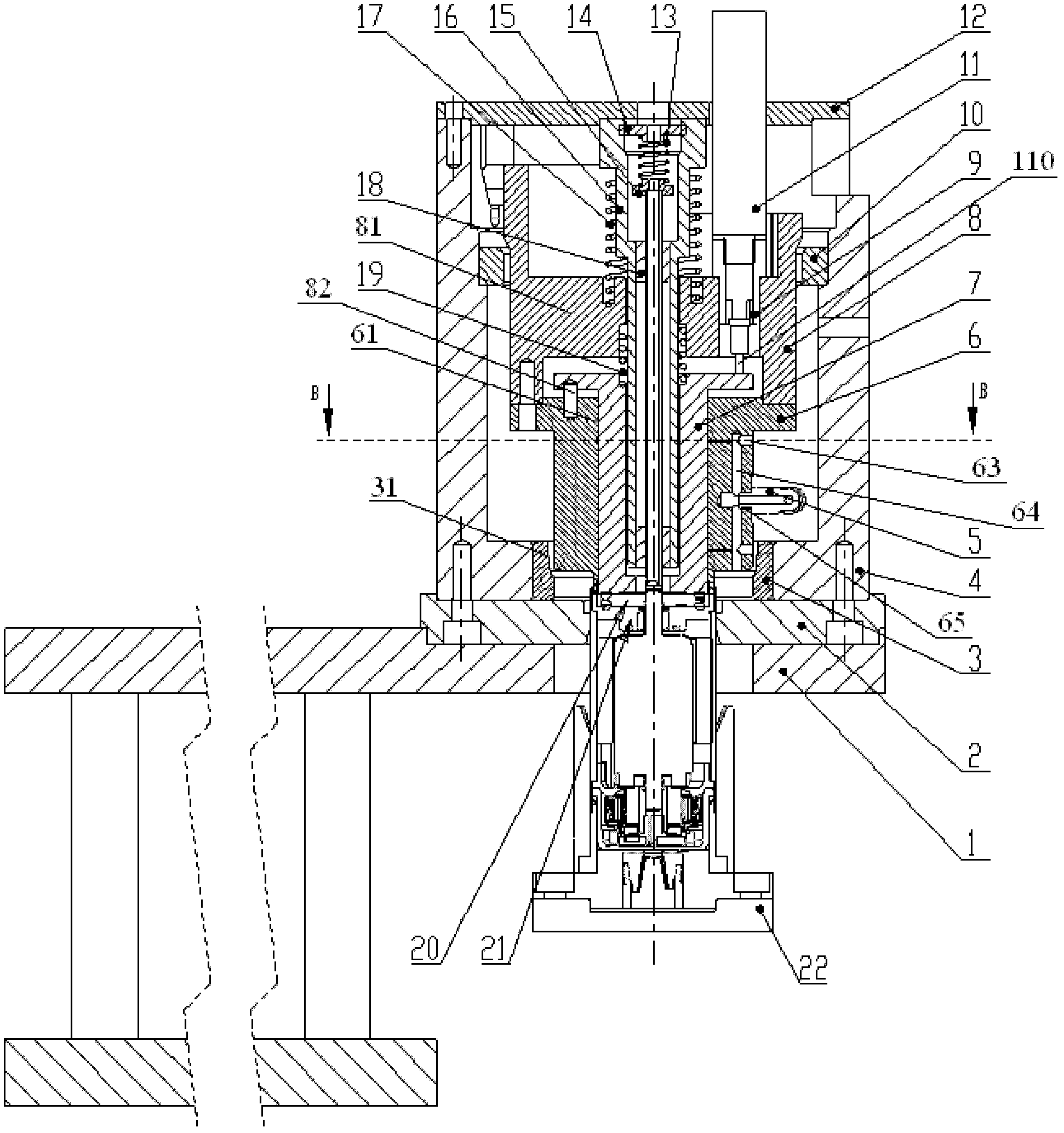

[0032] see Figure 1-Figure 4 , the present invention, that is, a measuring device for a tiny gap on the end face of a mechanical product, is used to measure the first workpiece (in this embodiment, the first workpiece is the impeller 20 in the automobile gasoline pump) and the second workpiece (in this embodiment Among them, the second workpiece is the gap between the parallel upper end surfaces of the oil outlet plate 21) in the automobile gasoline pump (the impeller 20 is embedded in the concave cavity of the upper end surface of the oil outlet plate 21), and the measuring device includes a support Plate 1, the bracket tube fixedly connected to the upper surface of the support plate 1, and the second workpiece pressing part 6 located in the inner cavity of the bracket tube, the first workpiece pressing shaft 7, the connecting sleeve 8, the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com