Compound slagging agent of converter and preparation method and applications thereof

A slagging agent and converter technology, applied in the direction of manufacturing converters, etc., to achieve the effect of increasing output, reducing consumption and good smelting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

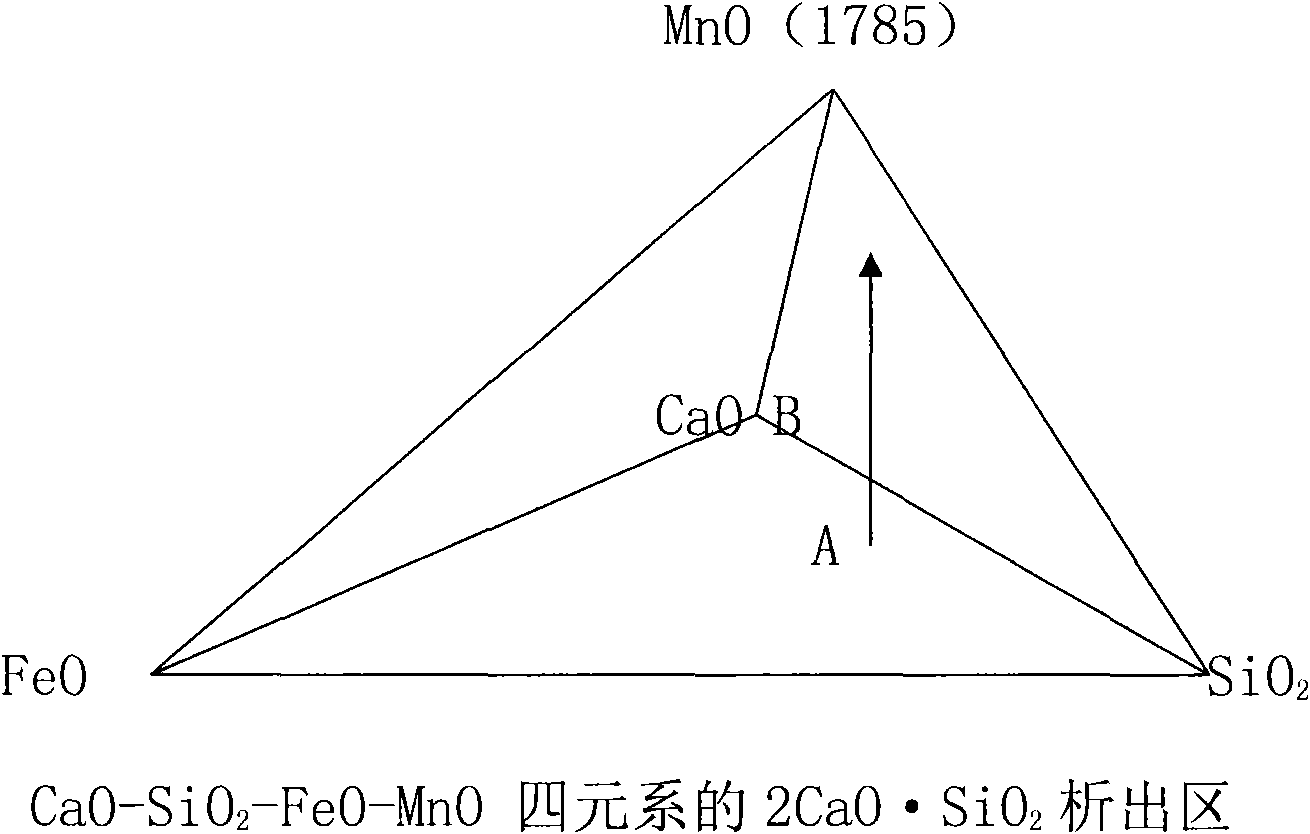

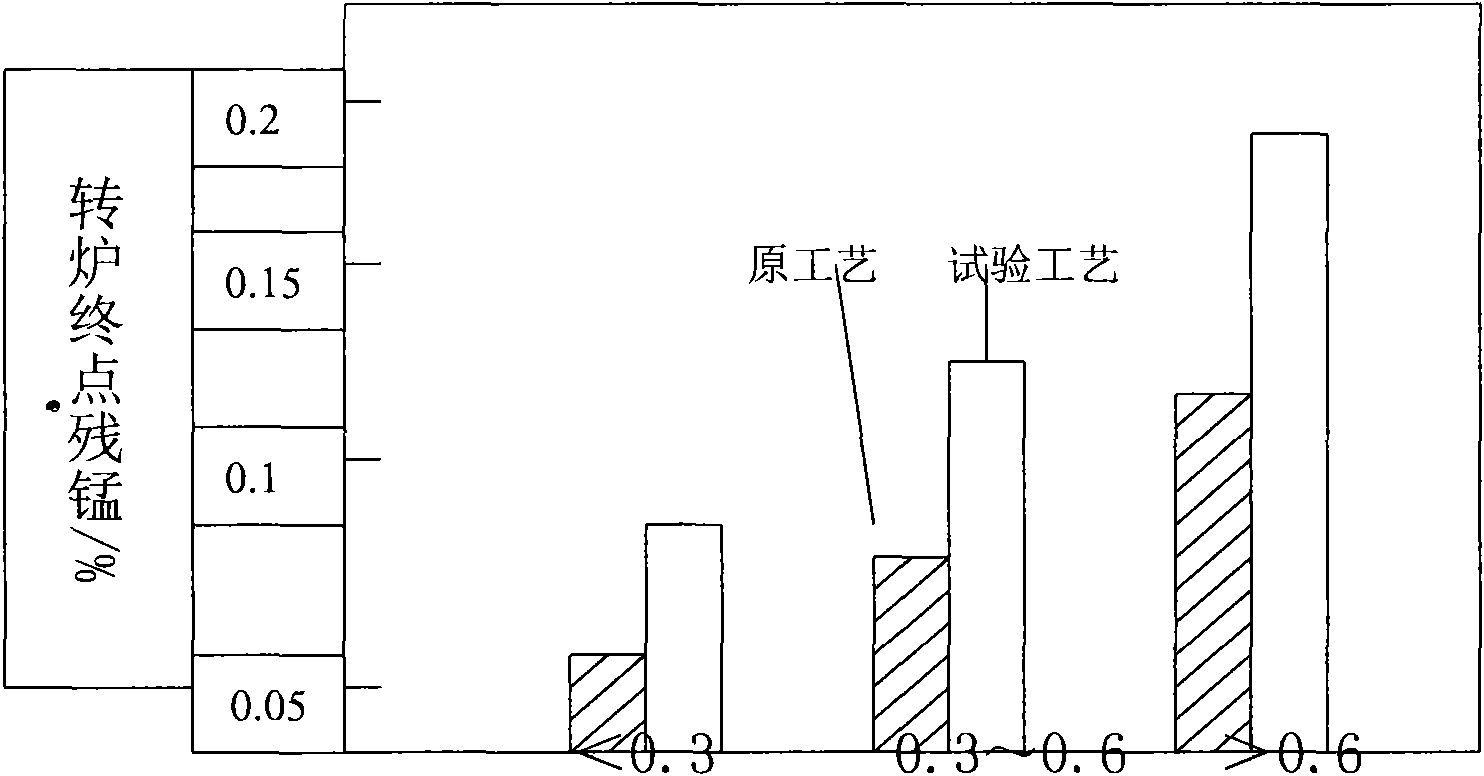

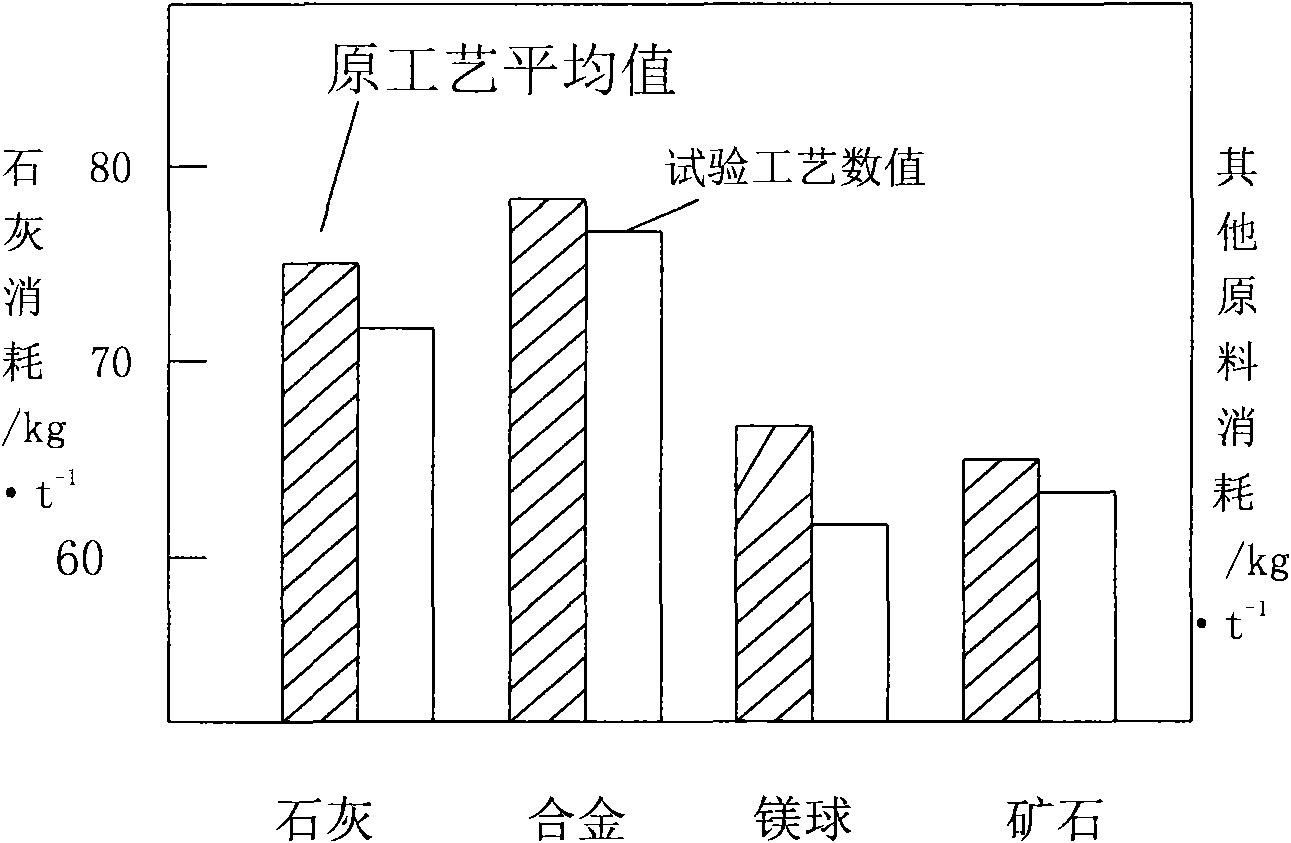

Method used

Image

Examples

Embodiment 1

[0045] A converter composite slag remover, the slag remover is composed of the following components by weight percentage:

[0046] MnO: 25% MgO: 4.2%

[0047] CaO: 7.8% Fe: 13.5%

[0048] Moisture: 8%, the balance is unavoidable impurities.

[0049] The preparation method of the above-mentioned converter composite slagging agent is as follows: it is prepared by crushing manganese ore, adding iron oxide, magnesium oxide and other auxiliary materials, kneading, briquetting, and baking.

[0050] The above-mentioned method of using the converter composite slag remover is based on the original process of the steel plant, adding 8 to 10 kg / t of the converter composite slag remover in the early stage of smelting, and the addition method is added in two batches. A batch of charge is added together, the quantity is 5-8kg / t, and the second batch of slag-removing agent is added 5 minutes before the blowing, the quantity is 2-4kg / t; at the same time, the position of the oxygen lance is ...

Embodiment 2

[0052] A converter composite slag remover, the slag remover is composed of the following components by weight percentage:

[0053] MnO: 34% MgO: 3.5%

[0054] CaO: 5.4% Fe: 12.2%

[0055] Moisture: 7.5%, the balance is unavoidable impurities.

[0056] The preparation method of the above converter composite slagging agent is as described in Example 1.

Embodiment 3

[0058] A converter composite slag remover, the slag remover is composed of the following components by weight percentage:

[0059] MnO: 40% MgO: 5.6%

[0060] CaO: 7.8% Fe: 14.2%

[0061] Moisture: 9.5%, the balance is unavoidable impurities.

[0062] The preparation method of the above converter composite slagging agent is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com