Refined-smelting ladle furnace carbon control deep desulphurization method for ultra-low-carbon steel production

A technology of ladle refining furnace and ultra-low carbon steel, which is applied in the field of deep desulfurization of molten steel and carbon-controlled deep desulfurization of ladle refining furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

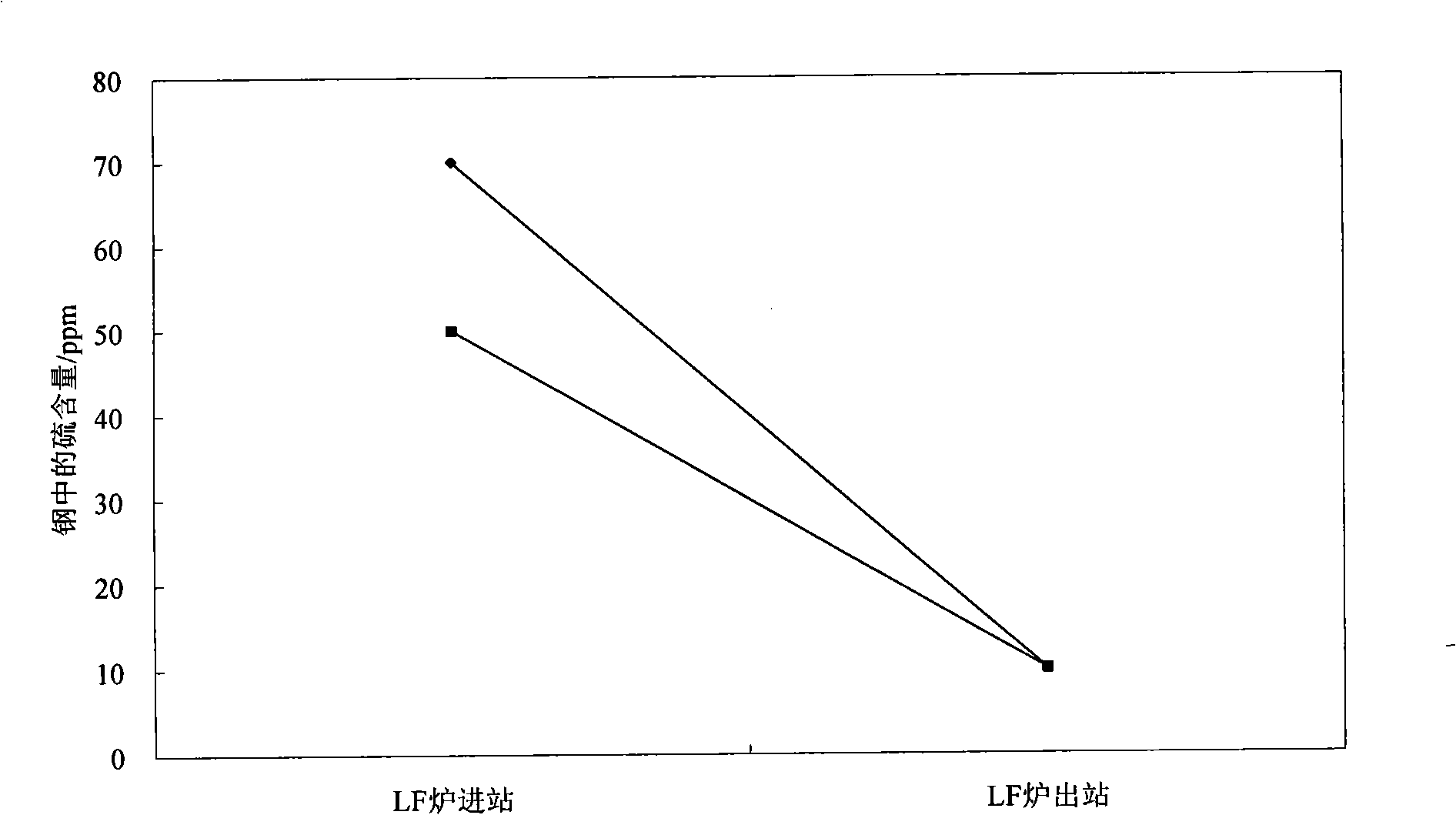

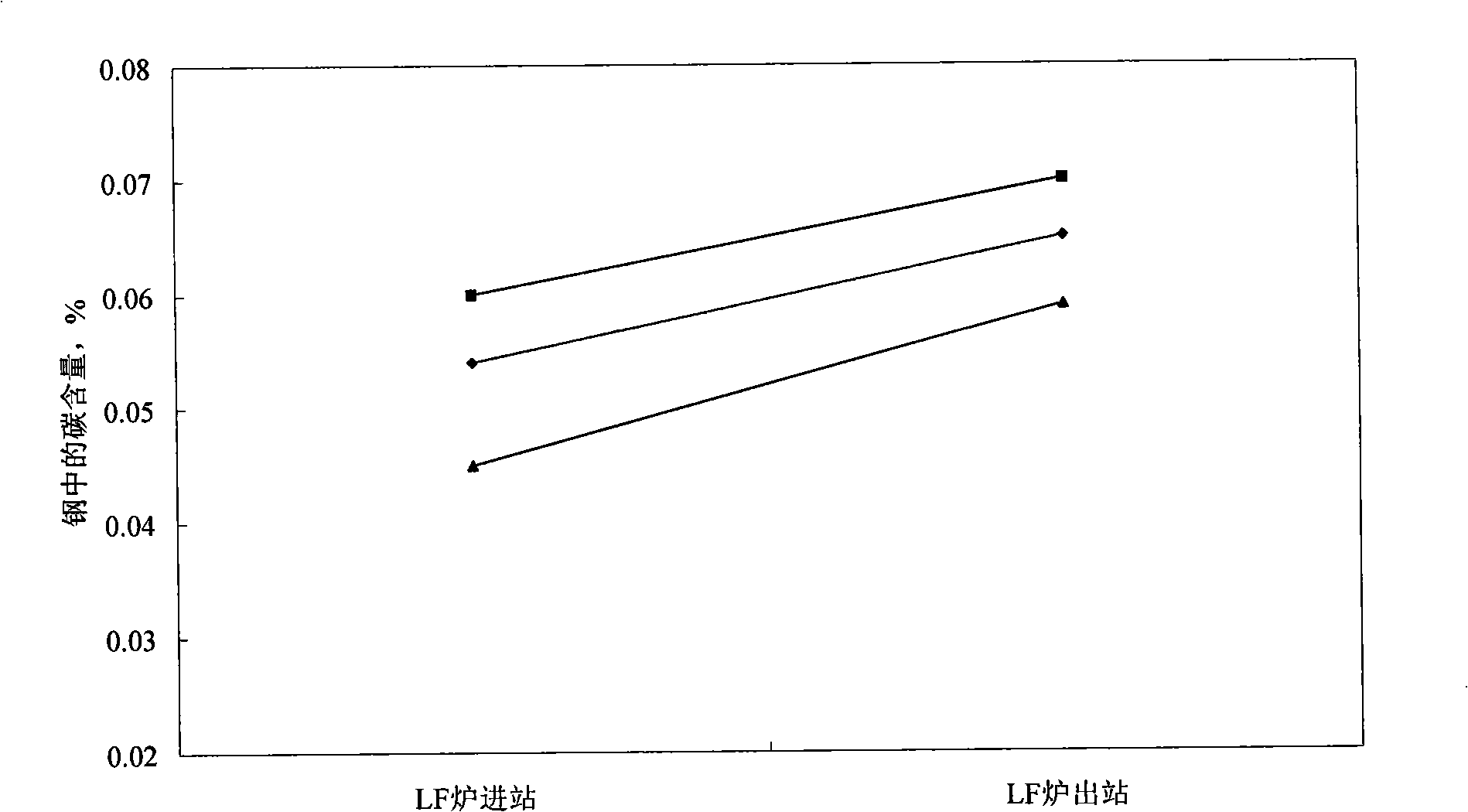

[0017] Implementation example 1: steel type X60, 100 tons of ladle, using the process of the present invention to control the increase of C and deep desulfurization: control the amount of slag in the converter, the slag thickness is 60mm; the temperature of the molten steel to the LF furnace is 1619 ° C, [Al] in the steel = 0.085%; add High alkalinity refining slag 10.5 kg / ton and Al particles 0.8 kg / ton, the first batch of high alkalinity refining slag added is 1 / 2 of the total amount, and the remaining slag is added after refining for 10 minutes; during the rapid deep desulfurization refining process Control the flow rate of bottom blowing argon gas. In the case of no lower electrode, use a large argon gas flow rate of 8NL / (min t) to first melt the slag. , to control the increase of C in molten steel; the oxidizing property of steel slag (FeO+MnO)≤1.0% at the end of refining, the basicity (CaO) / (SiO 2 ) = 8.0. The treatment period of the LF furnace is 65 minutes, and the co...

Embodiment 2

[0020] The content of [S] in steel decreased from 50ppm to 10ppm, and the desulfurization rate was 80%; the increase of [C] in steel was 0.009%. Implementation example 2: steel type X70, 100 tons of ladle, using the process of the present invention to control the increase of C and deep desulfurization: control the amount of slag under the converter, the slag thickness is 50mm; the temperature of molten steel to LF furnace is 1627 ° C, [Al] in the steel = 0.062%; add High alkalinity refining slag 12 kg / ton and Al particles 1.0 kg / ton, the first batch of high alkalinity refining slag added is 2 / 3 of the total amount, and the remaining slag is added after refining for 10 minutes; during the rapid deep desulfurization refining process Control the flow rate of bottom blowing argon gas. In the case of no lower electrode, use a large argon gas flow rate of 6NL / (min t) to first melt the slag. , to control the increase of C in molten steel; the oxidizing property of steel slag (FeO+MnO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com