Refined-smelting ladle furnace carbon control deep desulphurization method for ultra-low-carbon steel production

A technology of ladle refining furnace and ultra-low carbon steel, which is applied in the field of controlled carbon deep desulfurization of ladle refining furnace and deep desulfurization of molten steel. It can solve the problems that deep desulfurization cannot be carried out, and achieve the effect of shortening the smelting cycle and high-efficiency deep desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

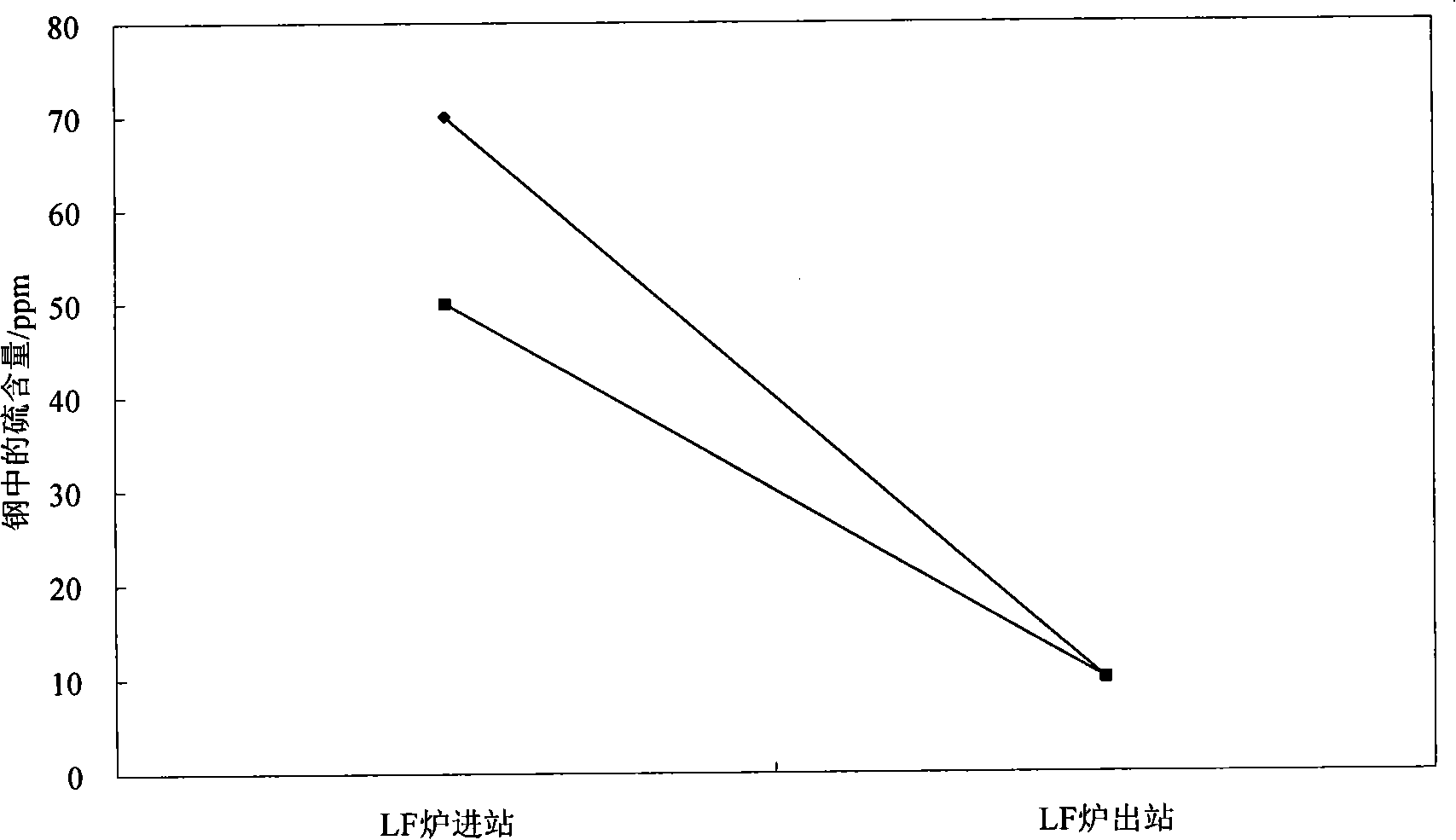

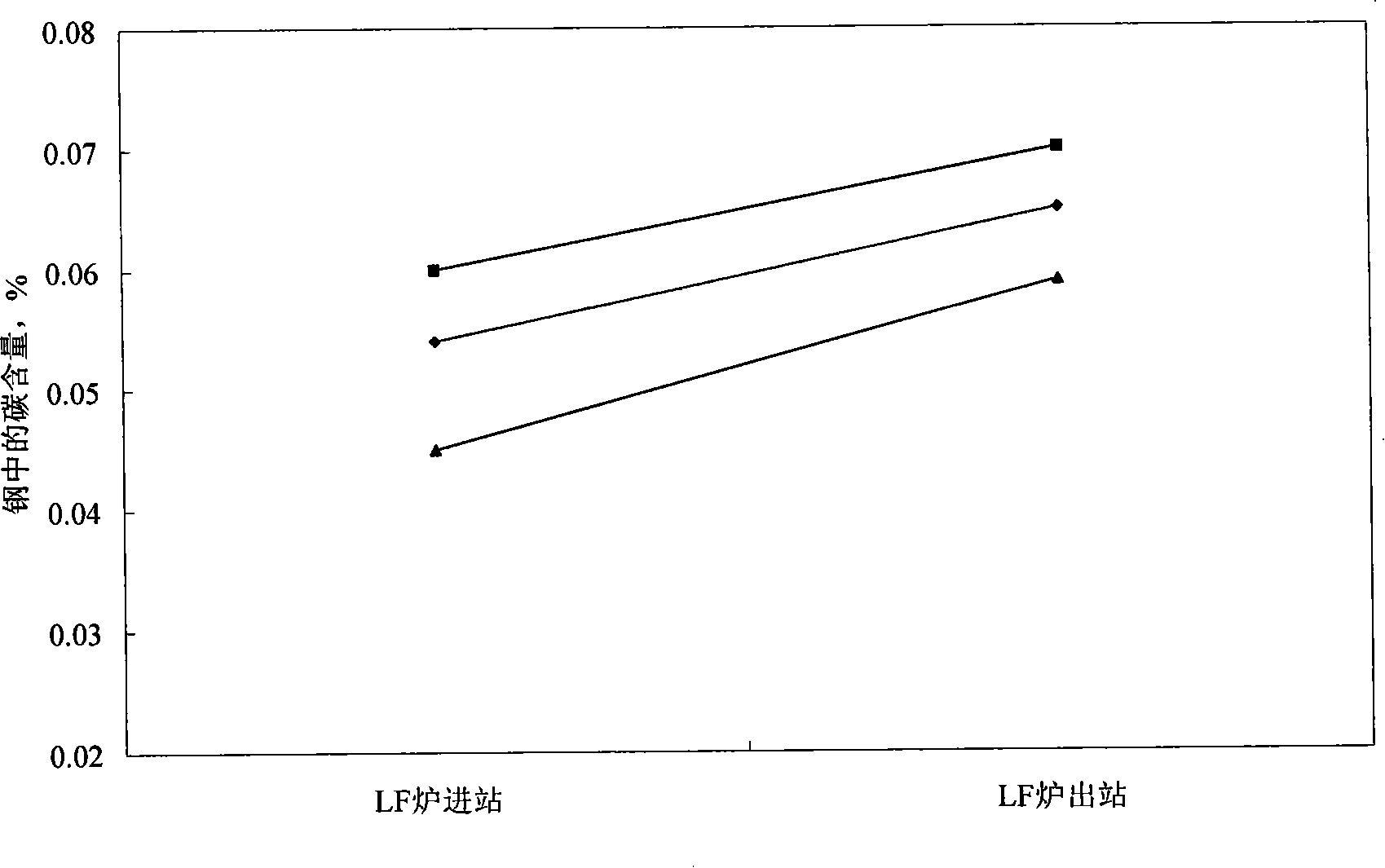

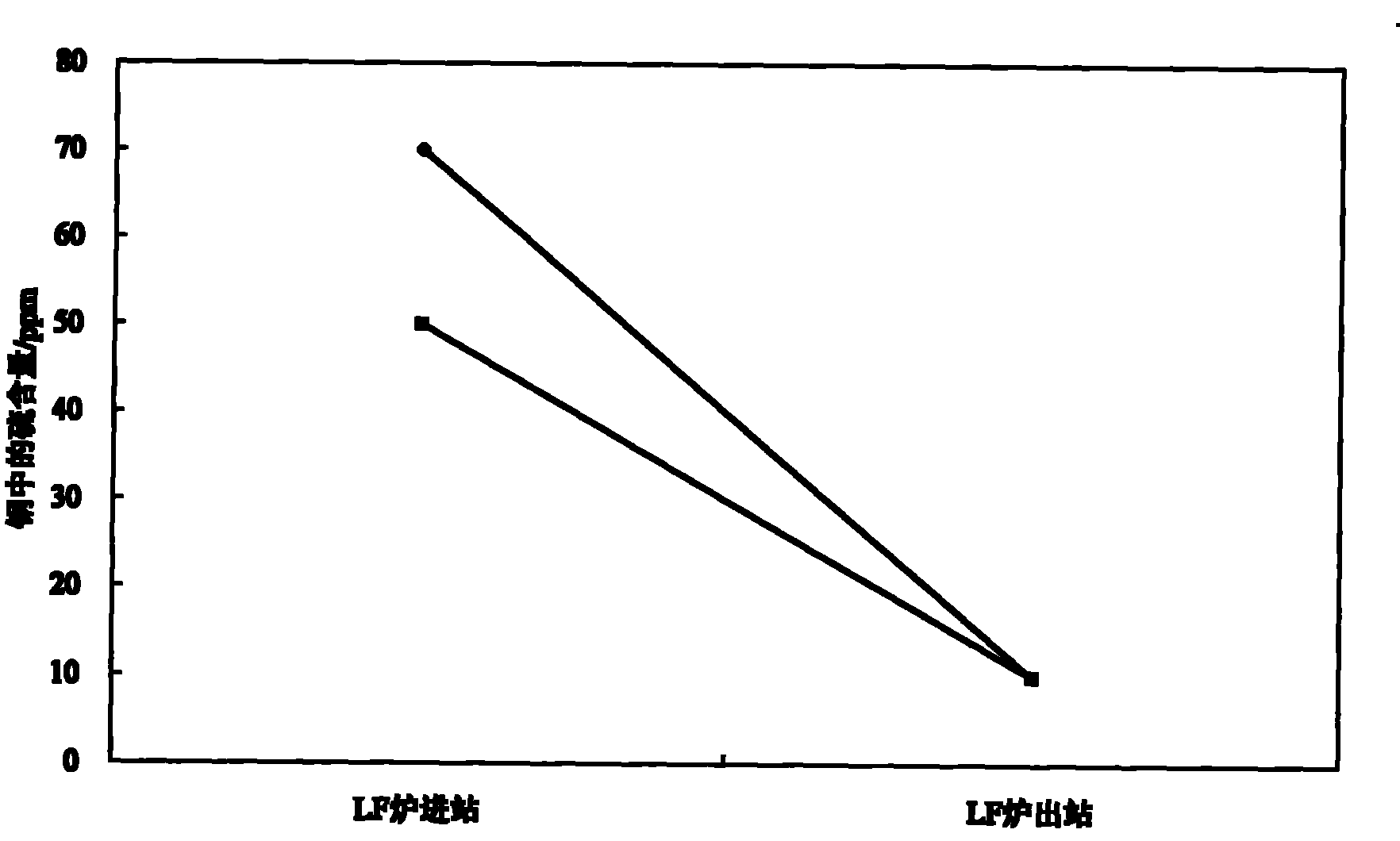

[0017] Implementation example 1: steel type X60, 100 tons of ladle, using the process of the present invention to control the increase of C and deep desulfurization: control the amount of slag in the converter, the slag thickness is 60mm; the temperature of the molten steel to the LF furnace is 1619 ° C, [Al] in the steel = 0.085%; add High alkalinity refining slag 10.5 kg / ton and Al particles 0.8 kg / ton, the first batch of high alkalinity refining slag added is 1 / 2 of the total amount, and the remaining slag is added after refining for 10 minutes; during the rapid deep desulfurization refining process Control the flow rate of bottom blowing argon gas. In the case of no lower electrode, use a large argon gas flow rate of 8NL / (min t) to first melt the slag. , to control the increase of C in molten steel; the oxidizing property of steel slag (FeO+MnO)≤1.0% at the end of refining, the basicity (CaO) / (SiO 2 ) = 8.0. The treatment period of the LF furnace is 65 minutes, and the co...

Embodiment 2

[0020] The content of [S] in steel decreased from 50ppm to 10ppm, and the desulfurization rate was 80%; the increase of [C] in steel was 0.009%. Implementation example 2: steel type X70, 100 tons of ladle, using the process of the present invention to control the increase of C and deep desulfurization: control the amount of slag under the converter, the slag thickness is 50mm; the temperature of molten steel to LF furnace is 1627 ° C, [Al] in the steel = 0.062%; add High alkalinity refining slag 12 kg / ton and Al particles 1.0 kg / ton, the first batch of high alkalinity refining slag added is 2 / 3 of the total amount, and the remaining slag is added after refining for 10 minutes; during the rapid deep desulfurization refining process Control the flow rate of bottom blowing argon gas. In the case of no lower electrode, use a large argon gas flow rate of 6NL / (min t) to first melt the slag. , to control the increase of C in molten steel; the oxidizing property of steel slag (FeO+MnO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com