Method for desulfurizing molten pig iron

A technology of molten iron and spray gun, which is applied in the field of desulfurization of molten iron, can solve the problem of reducing the amount of Al, and achieve the effects of reducing the loss of metal Al, improving processing efficiency, and improving reaction efficiency

Active Publication Date: 2011-08-03

NIPPON STEEL CORP

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] However, since the method described in this patent document 2 is treated in the atmosphere without using immersion free space, etc., the oxygen in the atmosphere reacts with the added Al, so the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

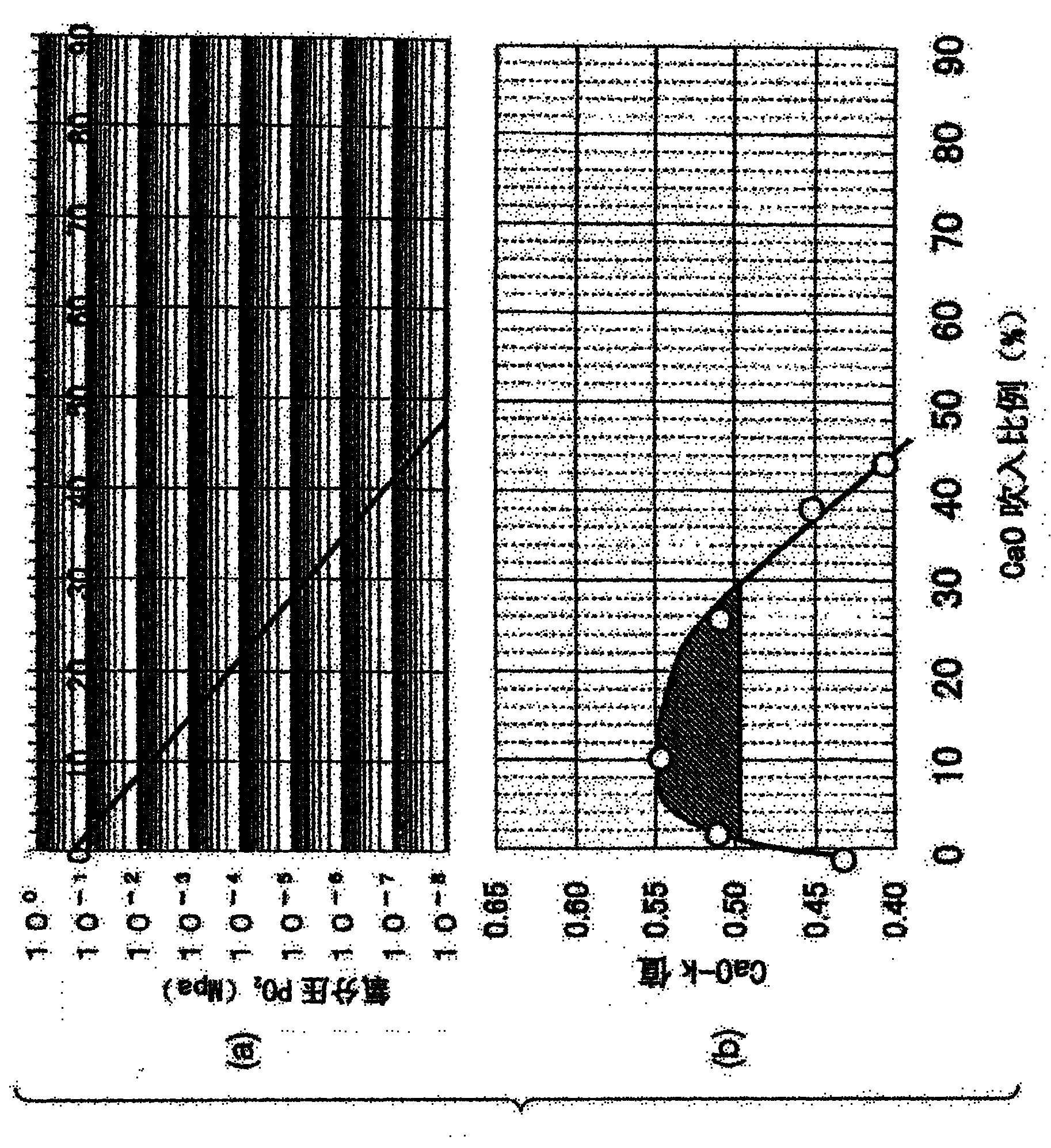

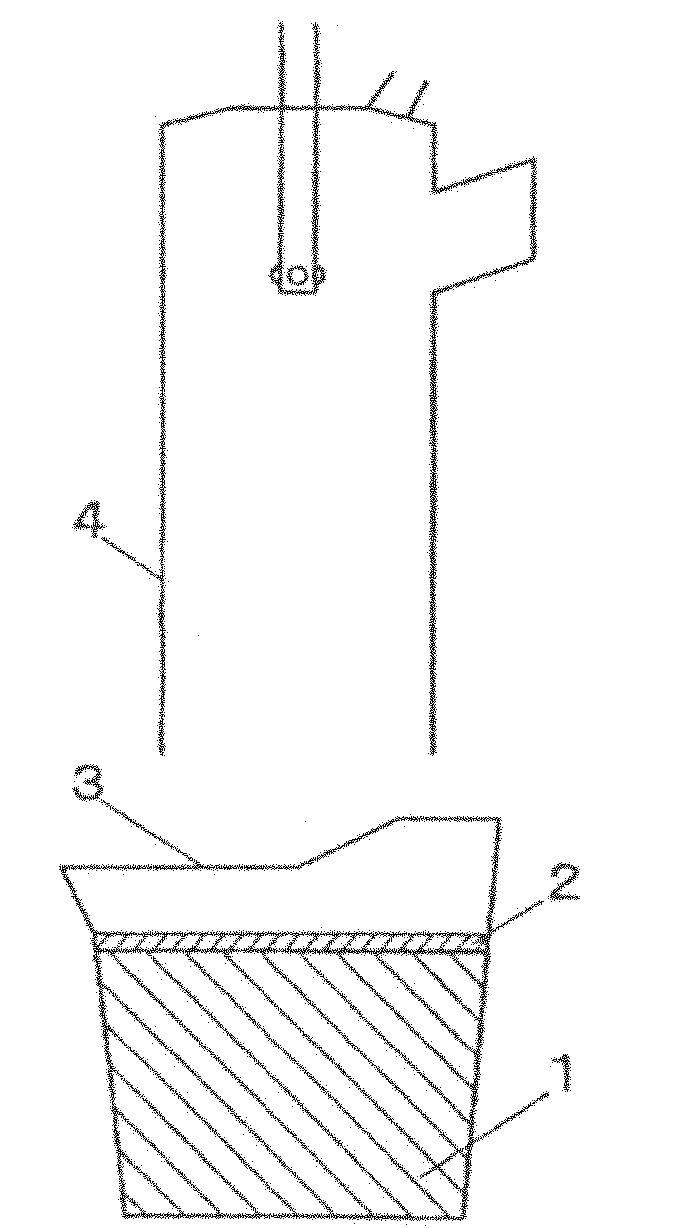

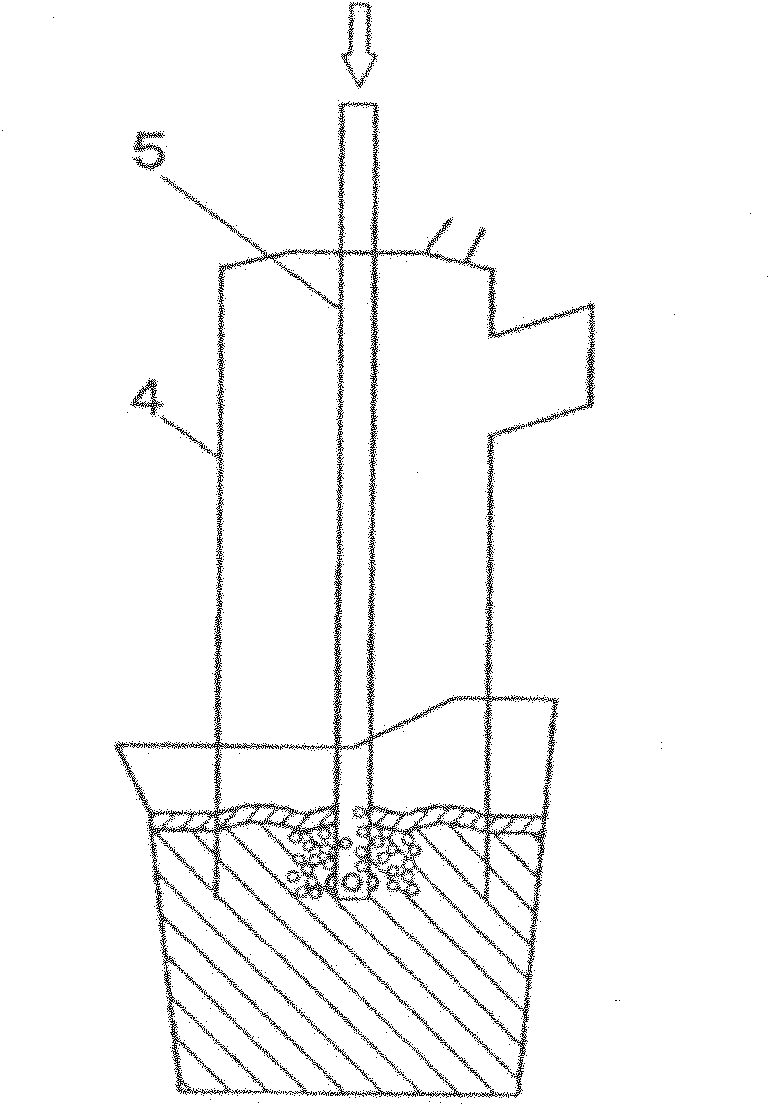

A method for the desulfurization of molten pig iron which comprises submerging a submersion-type free board and an injection lance in molten pig iron within a ladle and blowing an inert gas and CaO powder into the molten pig iron through the injection lance to desulfurize the molten pig iron, and which is provided with the step of adding metallic Al to the surface of the molten pig iron after theoxygen partial pressure within the submerged free board has been lowered to 0.1MPa or below by blowing the inert gas into the submerged free board and before 30mass% of the total CaO powder used has been blown into the molten pig iron.

Description

technical field [0001] The present invention relates to a method for desulfurizing molten iron by immersing a free board and a spray gun in molten iron in a molten iron tank, blowing inert gas and CaO powder from the spray gun, and in particular It relates to a molten iron desulfurization method in which metal Al is added to improve the reaction efficiency of CaO. [0002] This application is based on and claims priority to Japanese Patent Application Publication No. 2008-228502 filed on September 5, 2008, and the content thereof is incorporated herein. Background technique [0003] Since the molten iron from the blast furnace contains a lot of sulfur (S) that adversely affects the quality of the steel, desulfurization of the molten iron is performed as a process of the pretreatment of the molten iron. On the other hand, in recent years, the demand for the production of high-grade steel has increased, and the adoption of a cheaper low-sulfurization treatment method has been...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C1/02

CPCC21C7/072C21C7/0645C21C7/0037C21C7/0006C21C1/02

Inventor 八木恒熊仓政宣

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com