Green multifunctional detergent and its prepn process

A cleaning agent and multi-functional technology, applied in the direction of detergent composition, chemical instrument and method, surface active detergent composition, etc., can solve the problems of environmental adverse effects, unsuitable cleaning of electronic products, pollution of ecological environment of water areas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

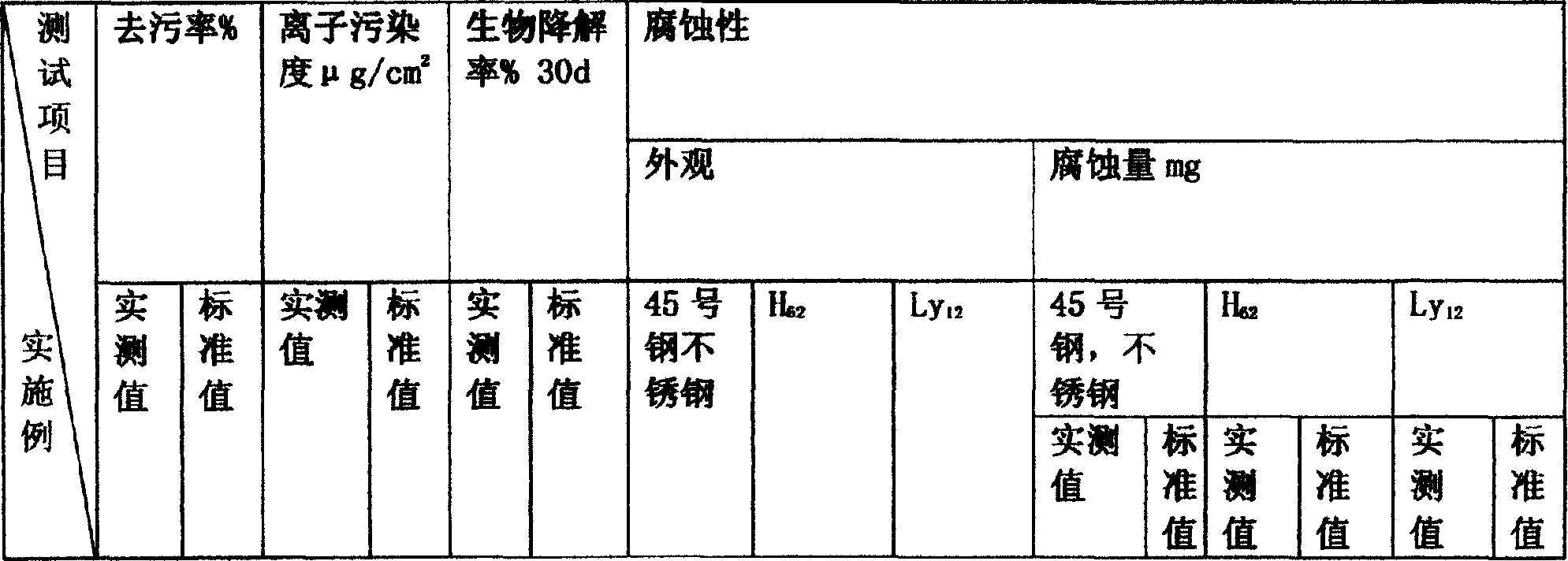

Image

Examples

Embodiment 1

[0026] Multifunctional environmental cleaning agent (unit: kg)

[0027] This is an efficient and environmentally friendly cleaning agent suitable for cleaning grease and dirt on various metal surfaces. It can be cleaned at room temperature or at 40-60°C.

[0028] Raw materials: SAS-60 4, AE09 2, AE07 2, LS45 1, propylene glycol 4, N-methylpyrrolidone 6, JFC 1, zeolite 12, JC-863 0.20, water 67.8.

[0029] Preparation:

[0030] 1. Put SAS-60, AE09, AE07, and LS45 surfactants in a stainless steel kettle, add co-solvent propylene glycol and N-methylpyrrolidone under stirring, and stir evenly.

[0031] 2. Put the water in another stainless steel kettle, add the chelating agent under stirring, after the zeolite P is dissolved, add the penetrant JFC and stir evenly.

[0032] 3. Add the homogeneous liquid prepared in 2 to the mixed solution prepared in 1, add the defoamer JC-863 under stirring, and continue stirring for 30 minutes to obtain the product.

Embodiment 2

[0034] Multifunctional environmental cleaning agent (unit: kg)

[0035] This is another high-efficiency and environmentally friendly cleaning agent suitable for cleaning grease and dirt on various metal surfaces. It can be cleaned at room temperature or at 40-60°C.

[0036] Raw materials: SAS-60 1, AES 1, APG 1, LS45 4, butyl glycol ether 4, N-methylpyrrolidone 4, JFC-2 2, layered crystalline sodium disilicate 10, TC-103 0.20, water 72.8.

[0037] The preparation method is the same as in Example 1.

Embodiment 3

[0039] Multifunctional environmental cleaning agent (unit: kg)

[0040] This is an efficient and environmentally friendly cleaning agent suitable for cleaning semiconductor material equipment and liquid crystal displays.

[0041] Raw materials: AES 2, AE09 3, AE07 3, LS45 1, propylene glycol 5, ethylene glycol butyl ether 6, JFC1, modified sodium polyacrylate 6, JC-863 0.1, water 72.9.

[0042] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com