Venturi tube dust removal device

A technology of dust removal device and Venturi tube, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve the problems that cannot meet the requirements of radioactive material removal, and achieve flow-induced vibration mitigation, liquid flow improvement, and air flow. The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

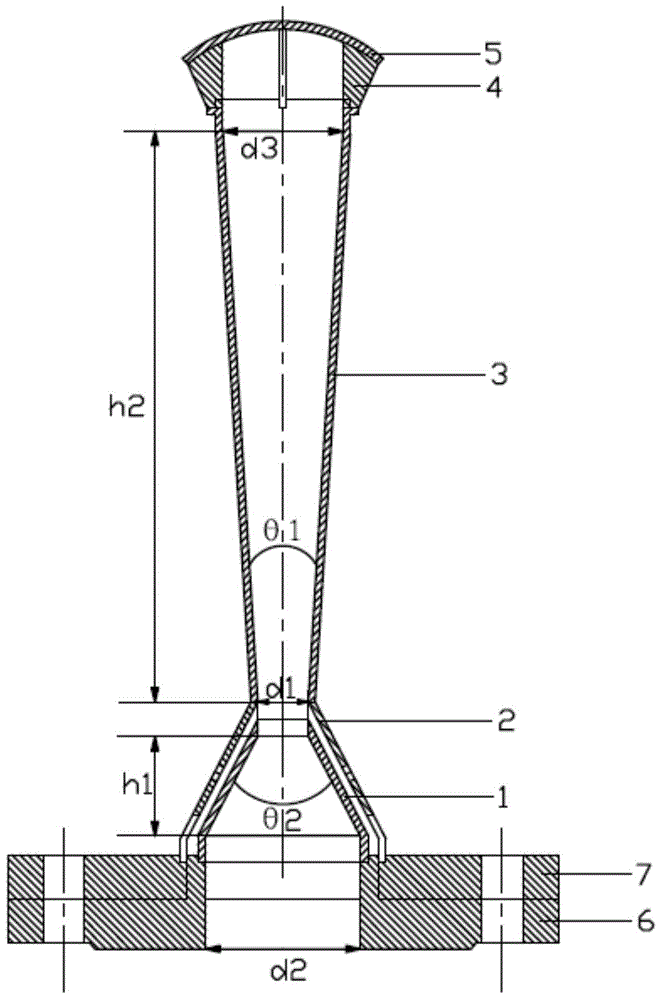

[0016] like figure 1 As shown, the Venturi tube dedusting device provided by the present invention is fixed on the dusty gas pipeline through the flange 6 . The Venturi tube dedusting device includes a constriction section 1, a throat section 2, and an expansion section 3, and the constriction section 1, the throat section 2, and the expansion section 3 are all conical shells. Wherein, the constriction section 1 and the throat section 2 are stacked, an annular channel is formed between the outer wall of the constriction section 1 and the inner wall of the throat section 2, and a plurality of small holes are arranged on the throat section 2; the lower end of the expansion section 3 and the The upper ends of the throat sections 2 are connected, and the top of the expansion section 3 is provided with supporting ribs 4 and outlet baffles 5, and openings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com