Regenerated acidic etching solution, copper recycling method and special device thereof

An acid etching solution and copper recovery technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of inconvenient operation, waste of resources and environment, unable to recover hydrochloric acid, etc., to reduce waste water discharge and increase the use of Longevity and the effect of realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

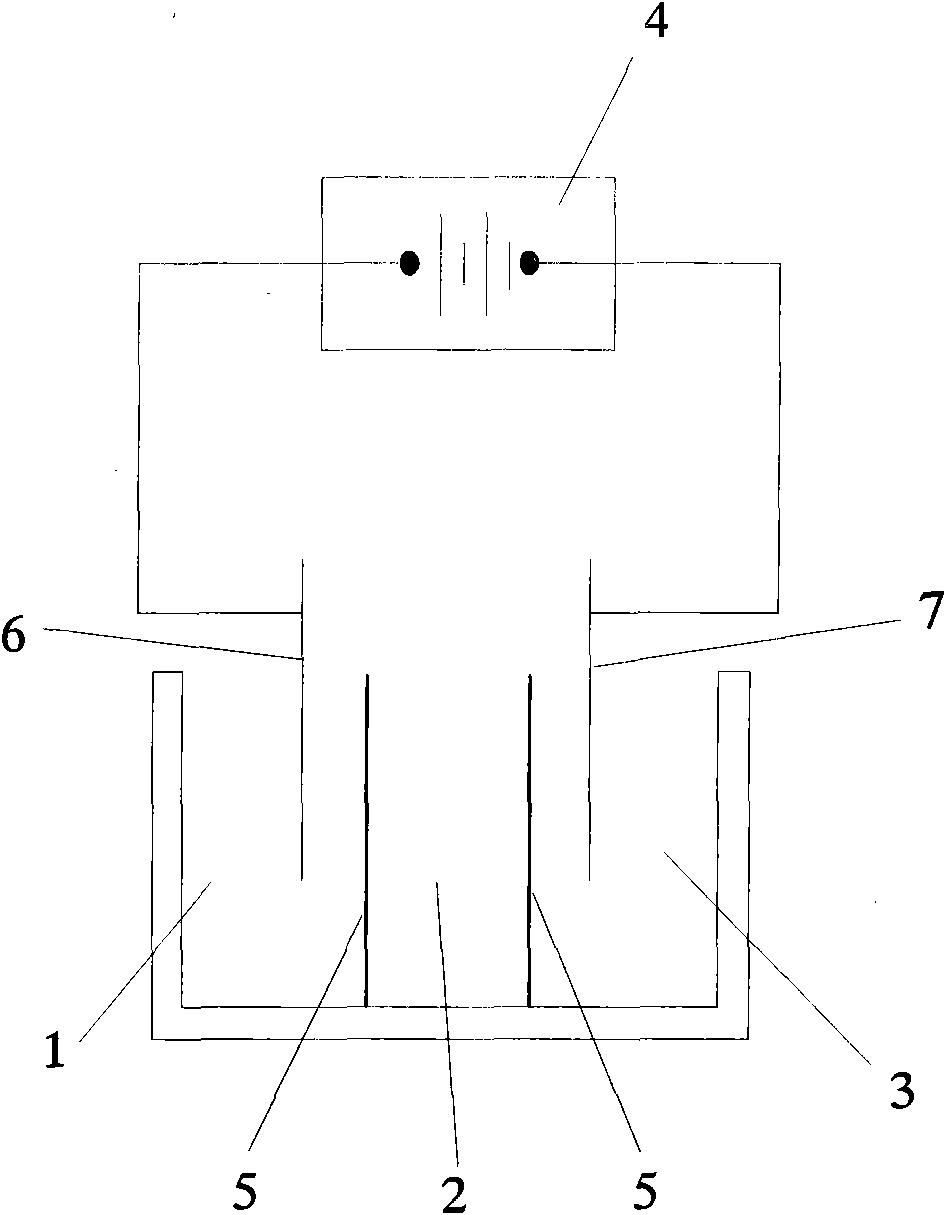

[0021] A method for regenerating acidic etching solution and reclaiming copper, adopting polyethylene cation exchange membrane 5 to divide rectangular polyethylene plastic electrolytic cell into three chambers of anode chamber 1, intermediate chamber 2 and cathode chamber 3, adding concentration of 5% sulfuric acid solution, add acidic etching waste liquid in the middle chamber 2, add copper sulfate solution with a copper ion concentration of 30g / L in the cathode chamber 3, use the lead-tin-calcium alloy plate as the anode electrolysis plate 6, and the stainless steel plate as the cathode electrolysis plate plate 7. The pole spacing between the two electrolytic plates is 110mm, the temperature is normal temperature, the voltage is 3V and the current density is 500A / m 2 . After 8 hours after electrolysis, when the copper ion concentration of the acidic etching waste solution drops below 1g / m, it can be returned as an etching solution for recycling.

[0022] The special device...

Embodiment 2

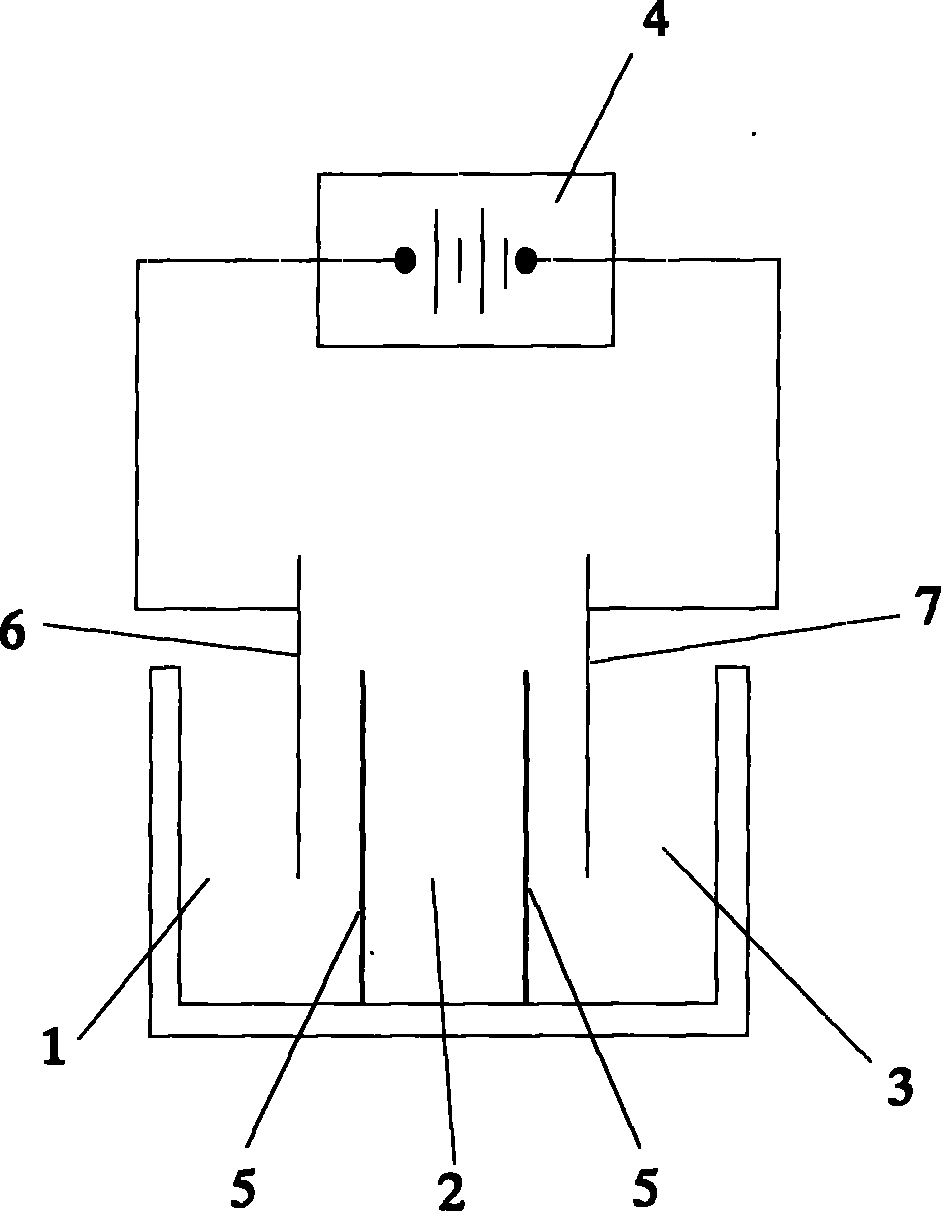

[0024] A method for regenerating acidic etching solution and recovering copper, using a polyvinylidene fluoride cation exchange membrane 5 to divide a rectangular polyethylene plastic electrolytic cell into three chambers: an anode chamber 1, an intermediate chamber 2, and a cathode chamber 3, and adding Concentration is 10% sulfuric acid solution, add acidic etching waste liquid in middle chamber 2, add copper sulfate solution that copper ion concentration is 40g / L in cathode chamber 3, take lead-tin-calcium alloy plate as anode electrolytic plate 6, stainless steel plate as Cathode electrolytic plate 7. The pole spacing between the two electrolytic plates is 150mm, the temperature is normal temperature, the voltage is 5V and the current density is 800A / m 2 . After 6 hours after electrolysis, when the copper ion concentration of the acidic etching waste solution drops below 1g / m, it can be returned as an etching solution for recycling.

[0025] The special device for the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com