Piston lever of reducer for automobile

A technology of automobile shock absorbers and piston rods, which is applied in the field of piston rods, can solve the problems that the ceramic film layer is difficult to combine, affects the normal movement of the piston rod, and shortens the service life of the piston rod, achieving small bending deformation, reduced inertia, and The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

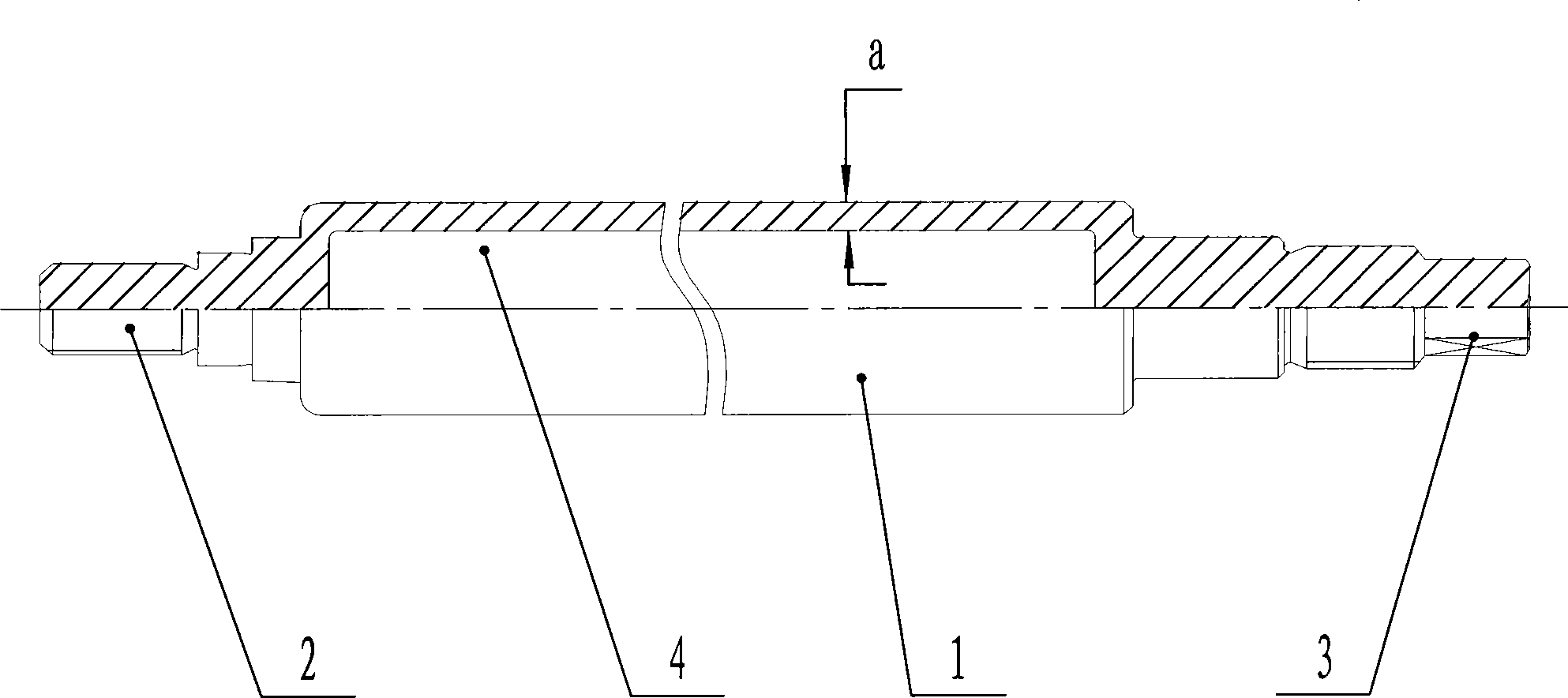

[0012] As shown in the drawings, the present invention includes a piston rod body 1 , a piston core rod 2 and a connecting screw 3 whose outer cylindrical surface is heat-treated or chrome-plated. The interior 4 of the piston rod body 1 is hollow, and the wall thickness a of the piston rod body 1 with the hollow interior 4 may range from 3 mm to 4 mm. The above-mentioned wall thickness a refers to the sum of the wall thickness of the piston rod body itself and the wall thickness of the chrome-plated layer. The connections between the piston core rod 2 and the connecting screw rod 3 and the end of the piston rod body 1 are friction pressure welding.

[0013] When in use, the piston core rod 2 is connected with the piston in the oil cylinder; the connecting screw rod 3 is connected with the chassis of the automobile; and the piston rod body 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com