Double-mold hydraulic press capable of quick changing mold

A technology of hydraulic presses and double templates, applied in presses, manufacturing tools, etc., can solve the problems of not being able to adapt to production needs, long downtime, and great impact on production efficiency, so as to shorten the auxiliary time for mold change, improve productivity, and improve accuracy. Sexual and Harmonious Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

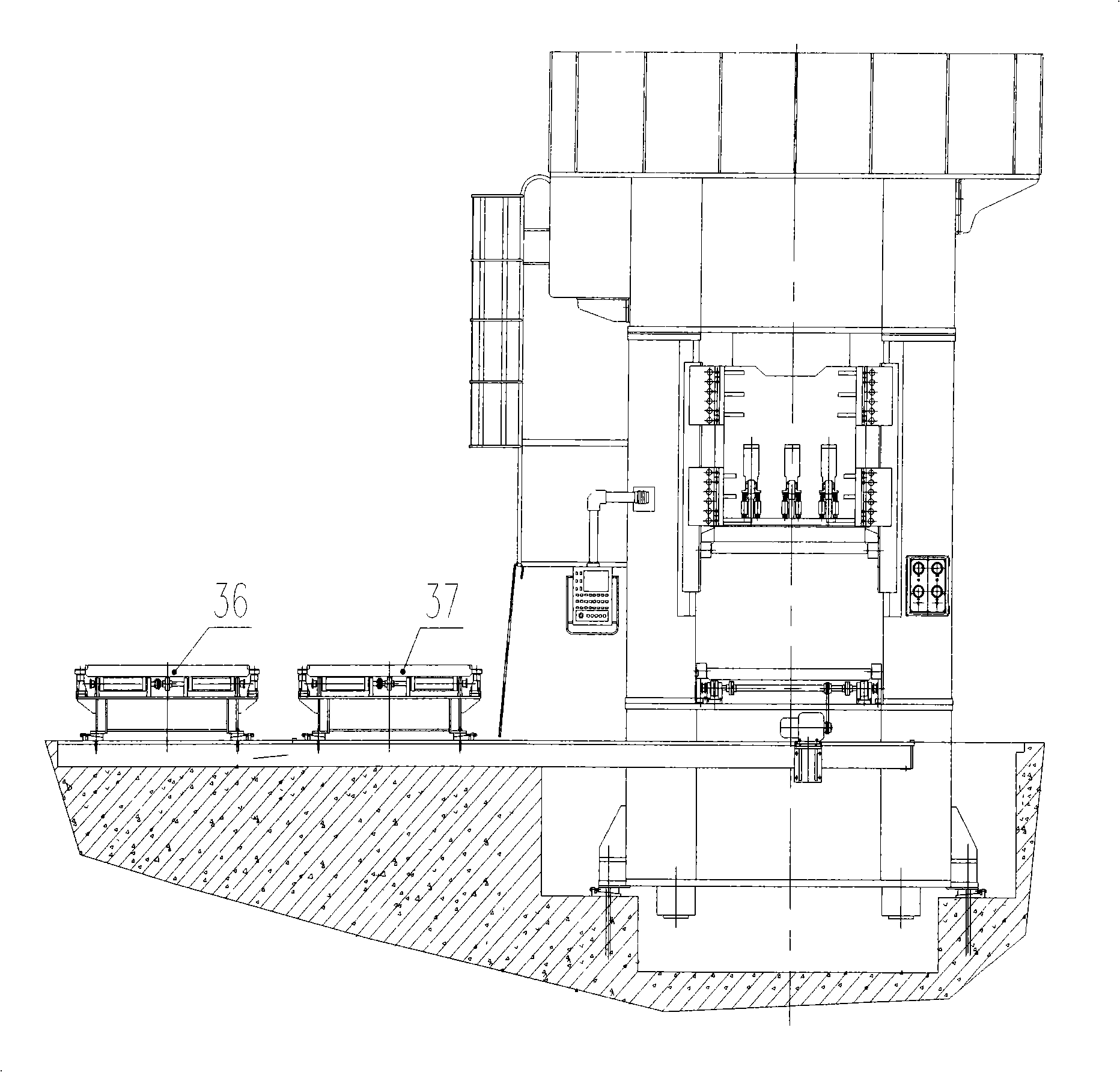

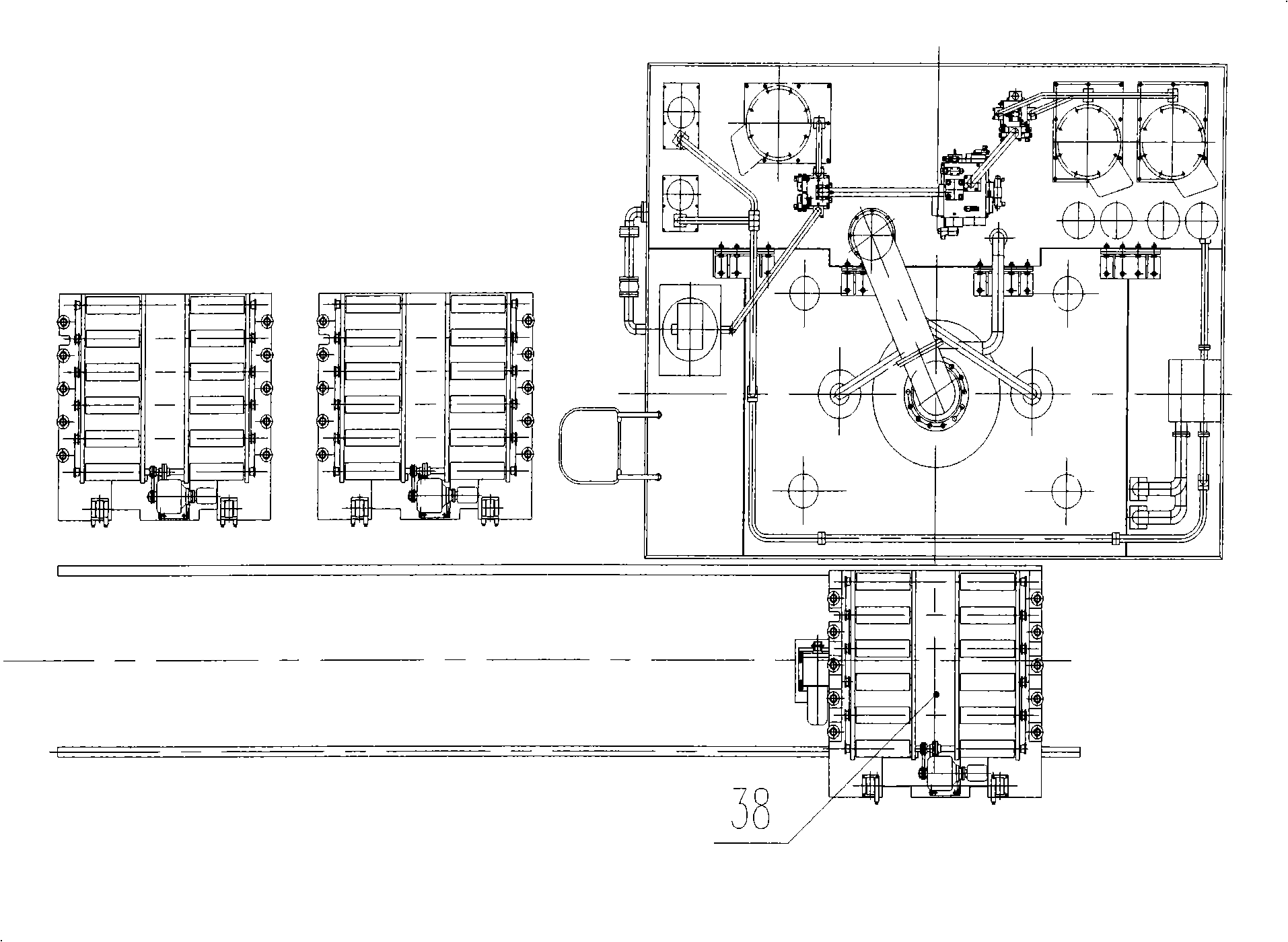

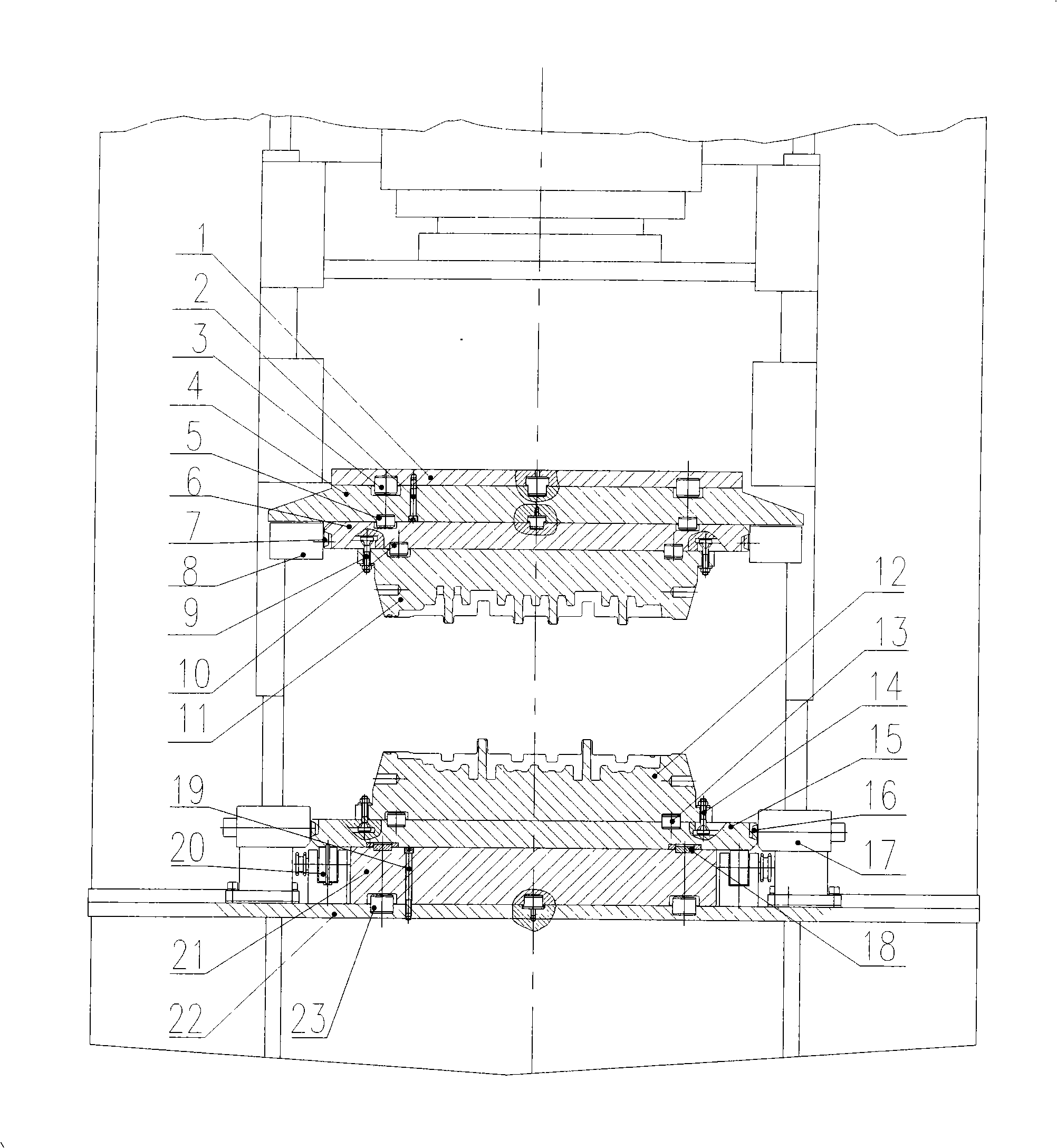

[0023] Below in conjunction with accompanying drawing, the present invention will be further described.

[0024] In the figure: 1 slider, 2nd slider and upper fixed backing plate connecting screw, 3 slider and upper fixed backing plate positioning pin, 4 upper fixing backing plate, 5 upper fixing backing plate and upper template positioning pin, 6 upper template, 7 Upper template 20° locking slope, 8 Upper locking cylinder, 9 Upper template and upper mold connecting screw, 10 Upper template and upper mold positioning pin, 11 Upper mold, 1 Second lower mold, 13 Lower mold and lower template positioning Pin, 14 lower mold and lower template connecting screw, 15 lower template, 16 lower template 20° locking slope, 17 lower locking cylinder, 18 lower template and lower fixed backing plate positioning pin, 19 lower fixed backing plate and lower beam Connecting screw, 20 hydraulic floating roller, 21 lower fixed backing plate, 22 lower beam, 23 lower fixed backing plate and lower be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com