Modular intelligent tool changeover method and management system

A technology for exchanging systems and cutting tools, applied in the direction of manufacturing tools, clamping, supporting, etc., can solve problems such as inconvenience, reduced production efficiency, and increased labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following describes the technical means adopted by the present invention to achieve the intended purpose of the invention in conjunction with the drawings and preferred embodiments of the present invention.

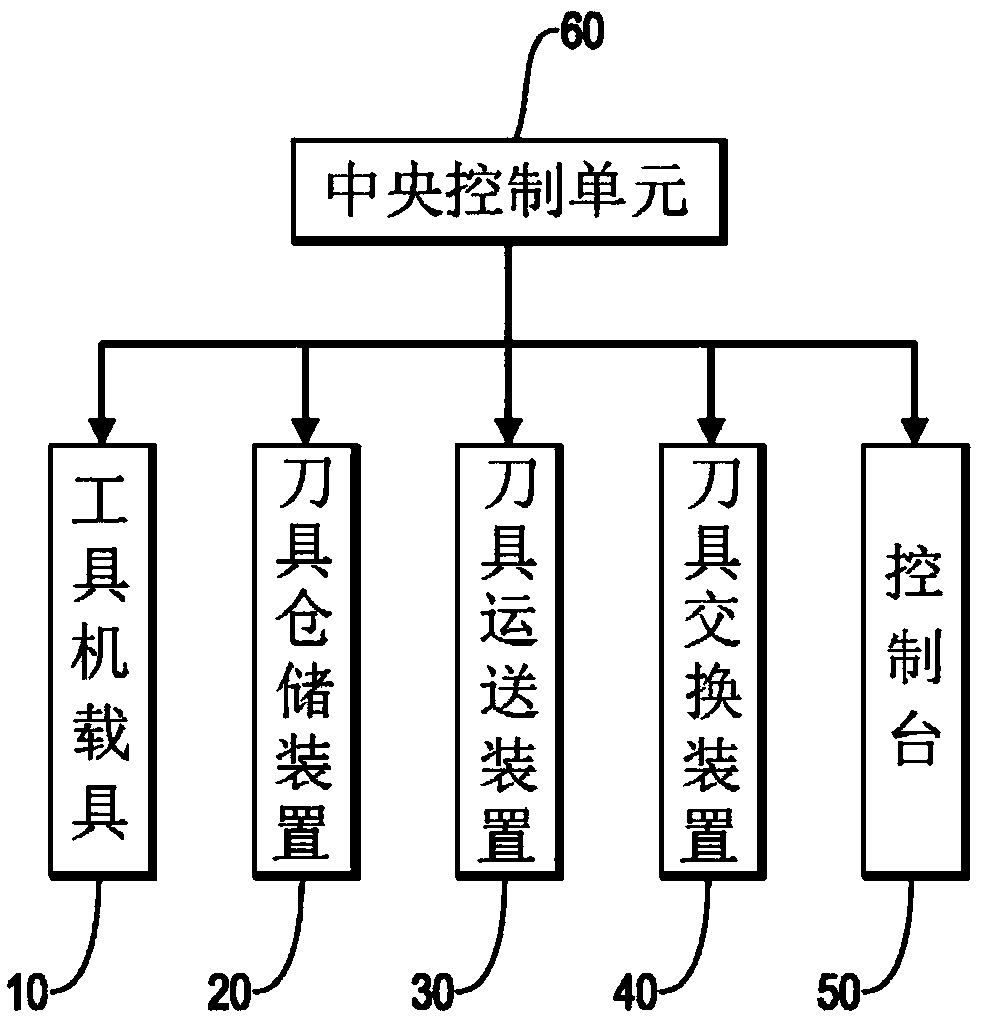

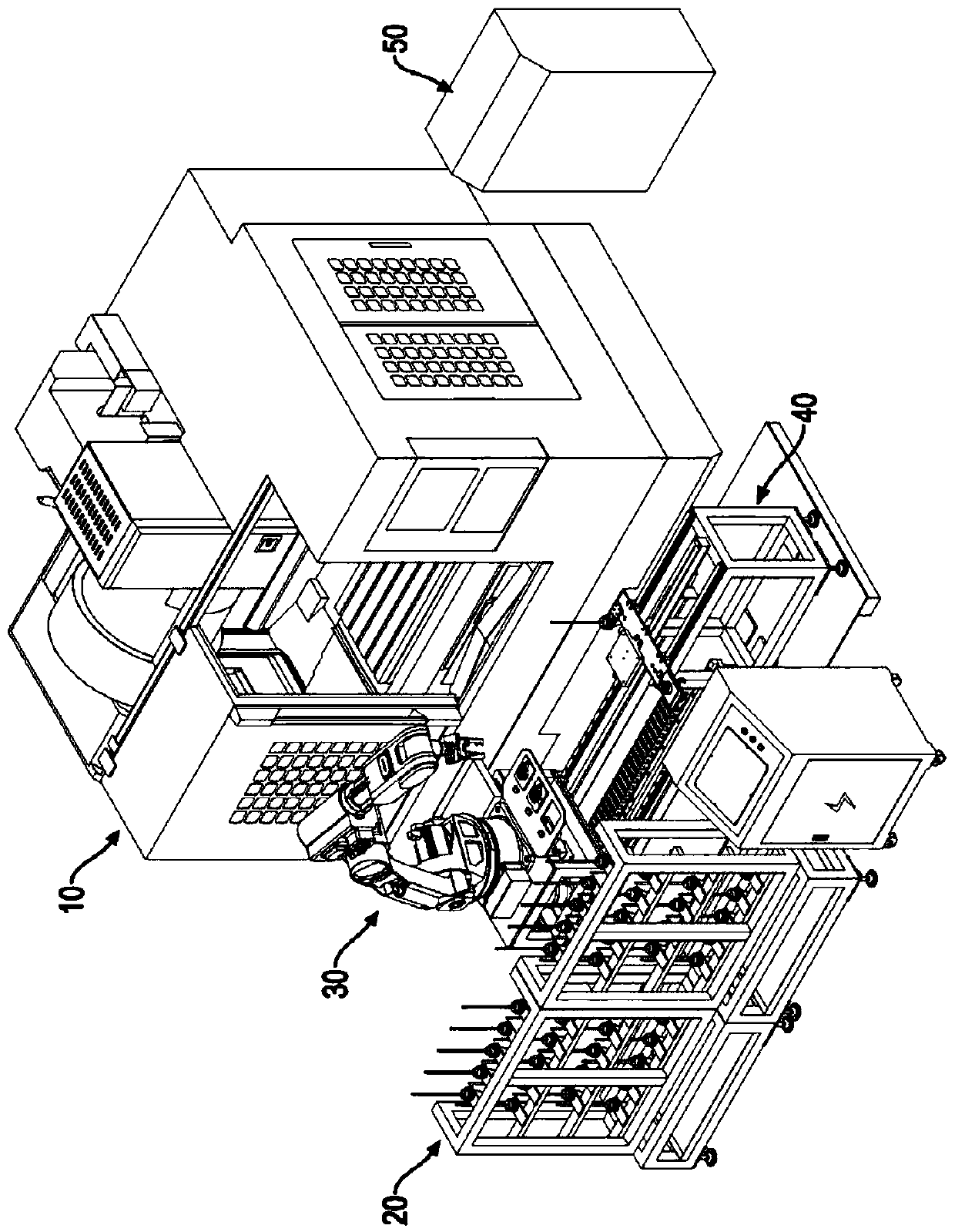

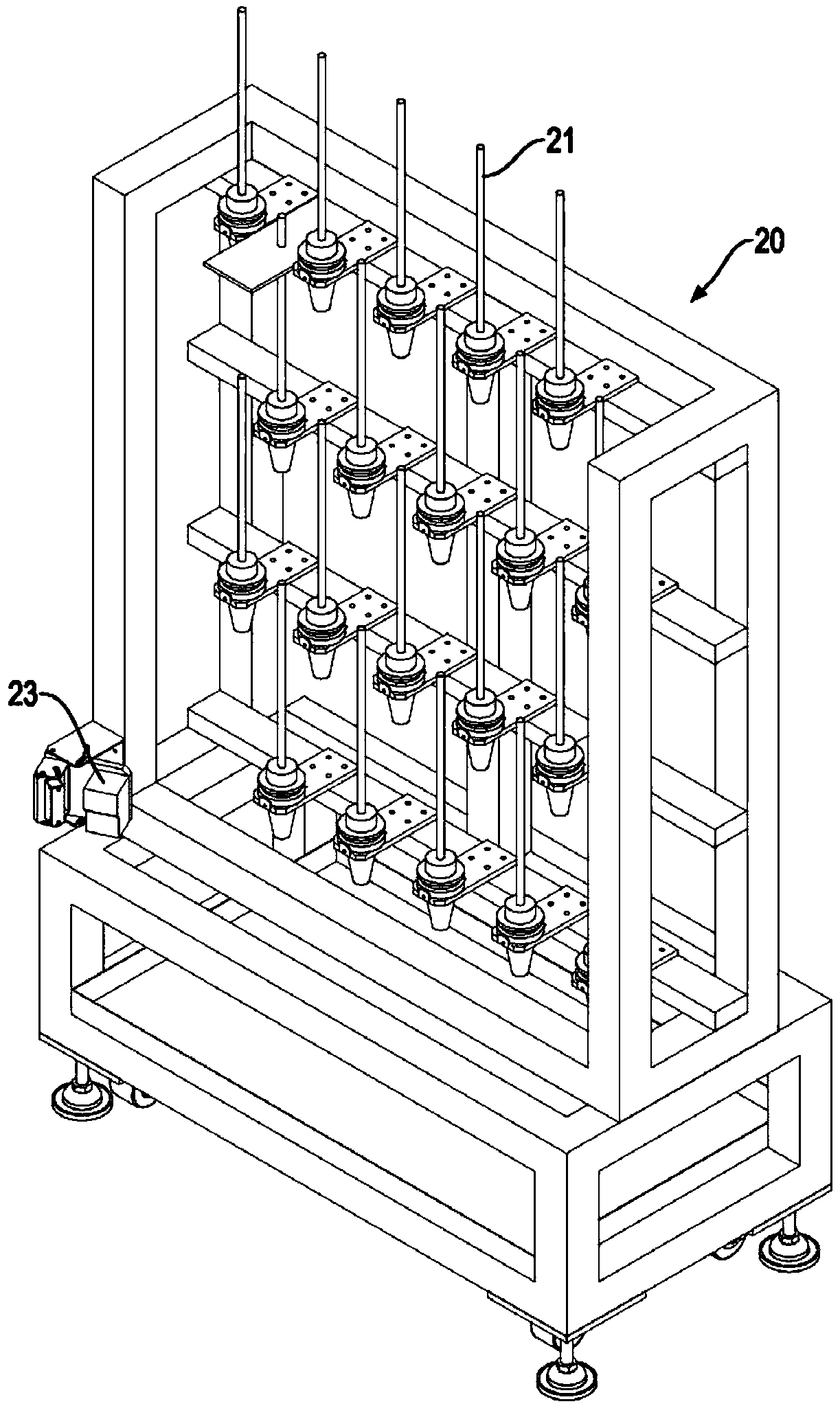

[0042] See figure 1 and figure 2 , The present invention is an intelligent tool exchange system applied to machine tools, which is used in a production line, and includes: a machine tool carrier 10, a tool storage device 20, a tool transport device 30, and a tool exchange device 40 , A console 50 and a central control unit 60.

[0043] The machine tool carrier 10 is provided with a tool detection device for measuring the length and diameter of the tool used in the machine tool 90; the machine tool carrier 10 further includes a control module, the control module including A central processing unit, a communication circuit, a storage circuit, an input / output circuit and a display are used to record and send detection information of the tool. Since the control module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com