Truss manipulator finger quick-change mechanism as well as pneumatic claw assembly and hand claw assembly for mounting finger quick-change mechanism

A manipulator and finger technology, which is applied in the field of finger quick changer, can solve the problems of iron filings and cutting fluid mechanical problems, complicated connection, gas cutoff, etc., so as to shorten the production interruption time, reduce the input of manpower, and improve the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

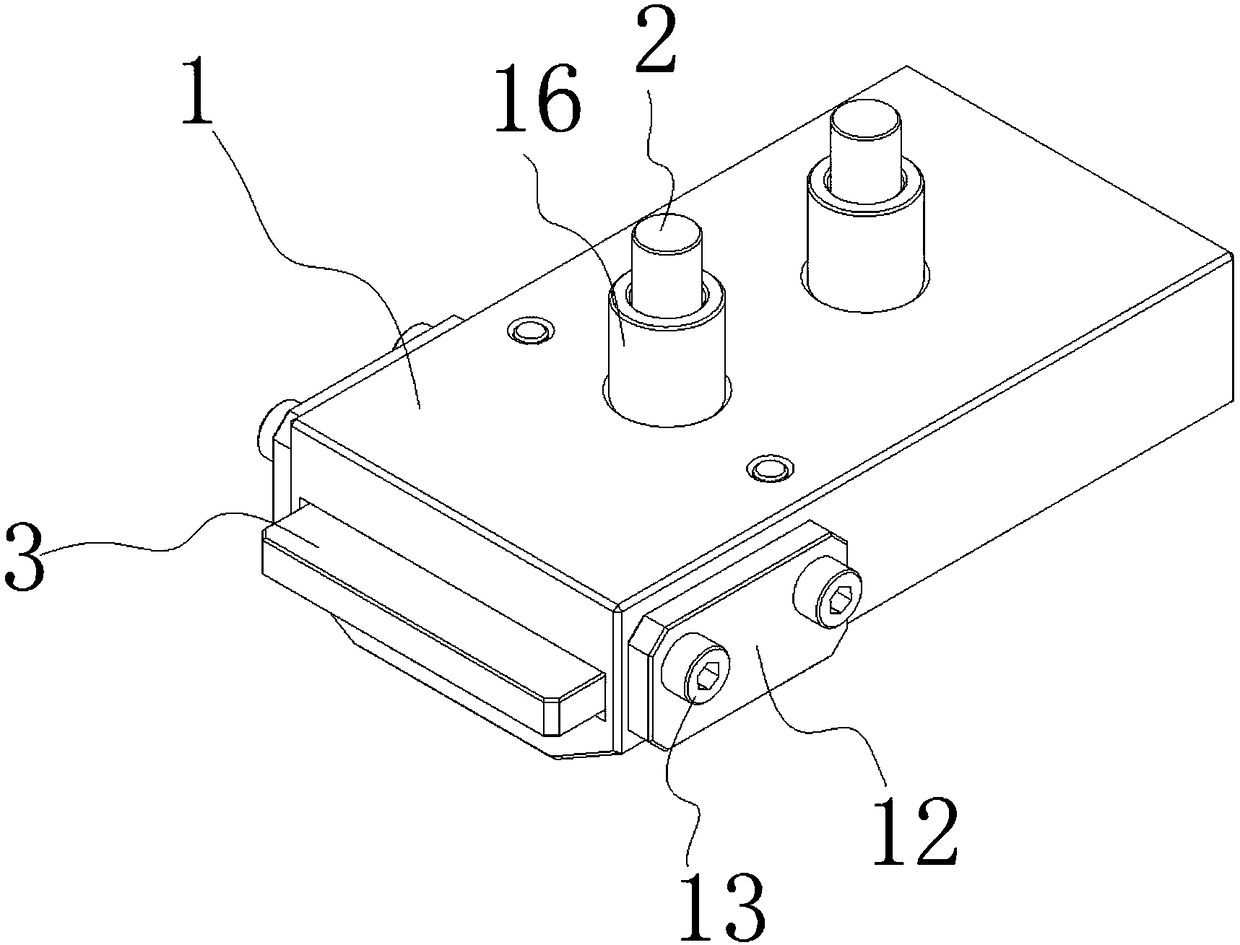

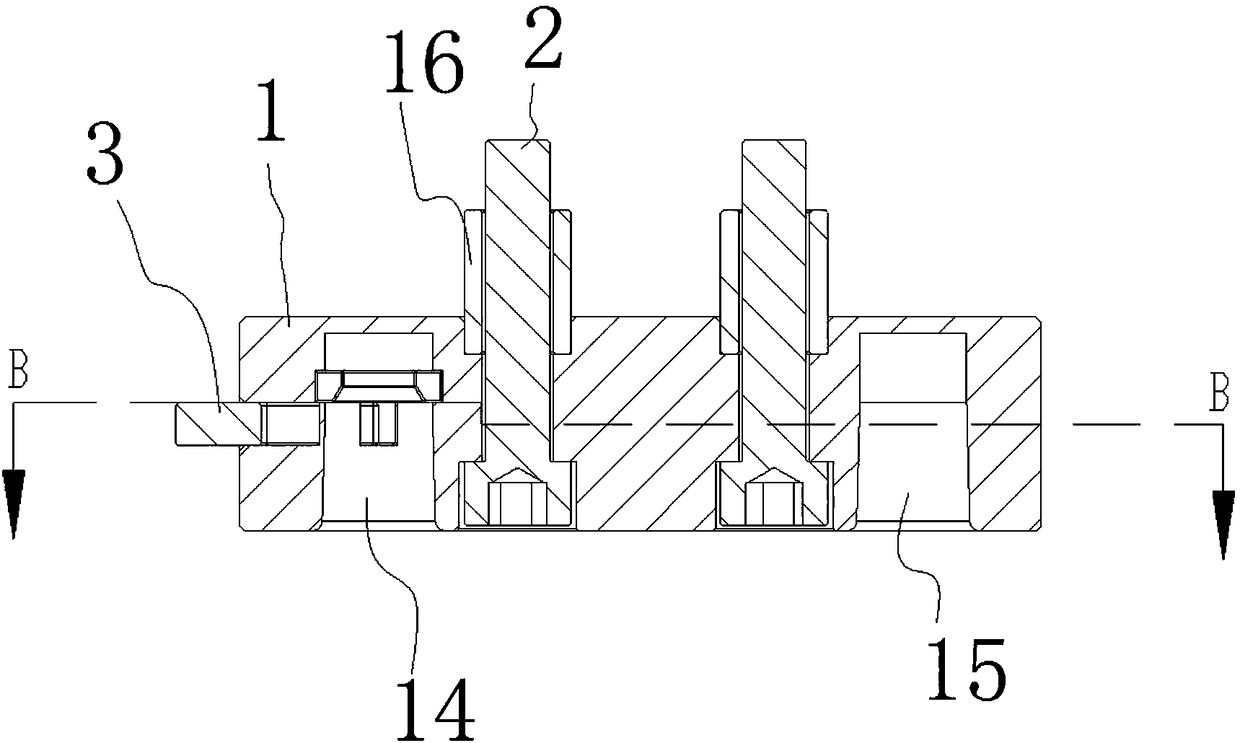

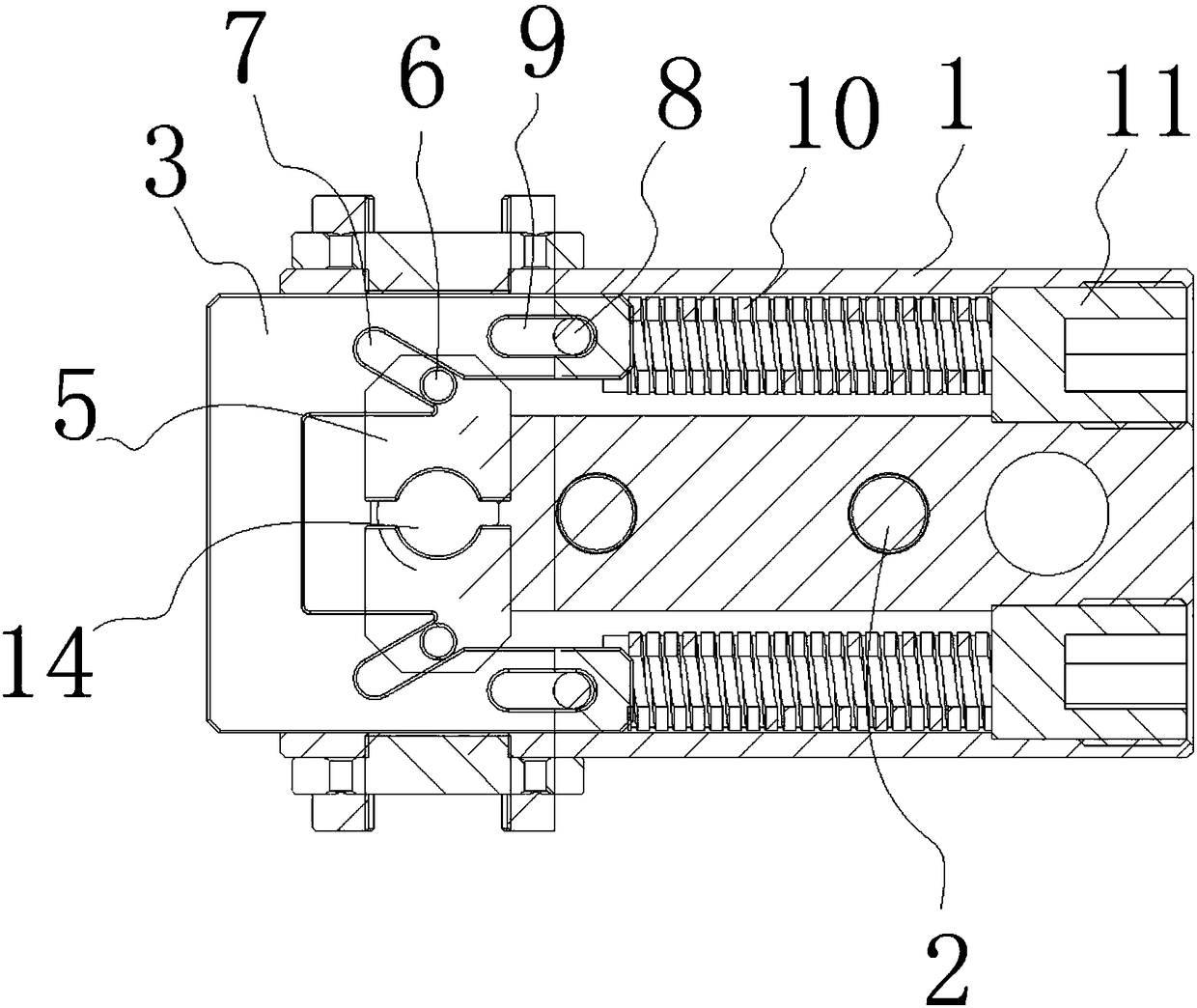

[0051] Embodiment 1: As shown in the figure, a truss manipulator finger quick-change mechanism includes a finger quick-change base 1, and a number of upwardly extending positioning bolts 2 are arranged in the finger quick-change base 1. The fingers The quick-change machine base 1 is provided with a locking plate guide plate 3 elastically positioned with the finger quick-change machine base 1, and the said finger quick-change machine base 1 is provided with at least one lock plate guide plate 3 that is movable and locked. The locking hole 4, the outer end of the locking piece guide plate 3 extends out of the outer wall of the finger quick change machine base 1 .

[0052] The said finger quick-change base 1 is provided with a locking piece (5) which is movable and locked with the locking hole 4, and the two ends of the said locking piece 5 are respectively provided with stop pins 6, and said The locking piece guide plate (3) is provided with a stop slot 7, the stop pin 6 is limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com