Shroud ring external fluid infusion hydraulic pressure expanding and reinforcing process for turbine generator

A turbo-generator and hydraulic bulging technology, applied to metal processing equipment, etc., can solve the problems of difficult organization of specialized production, difficult control of the forming process, large machining allowance, etc., and facilitate the organization of specialized production and forming process Easy to control and reduce the effect of machining allowance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

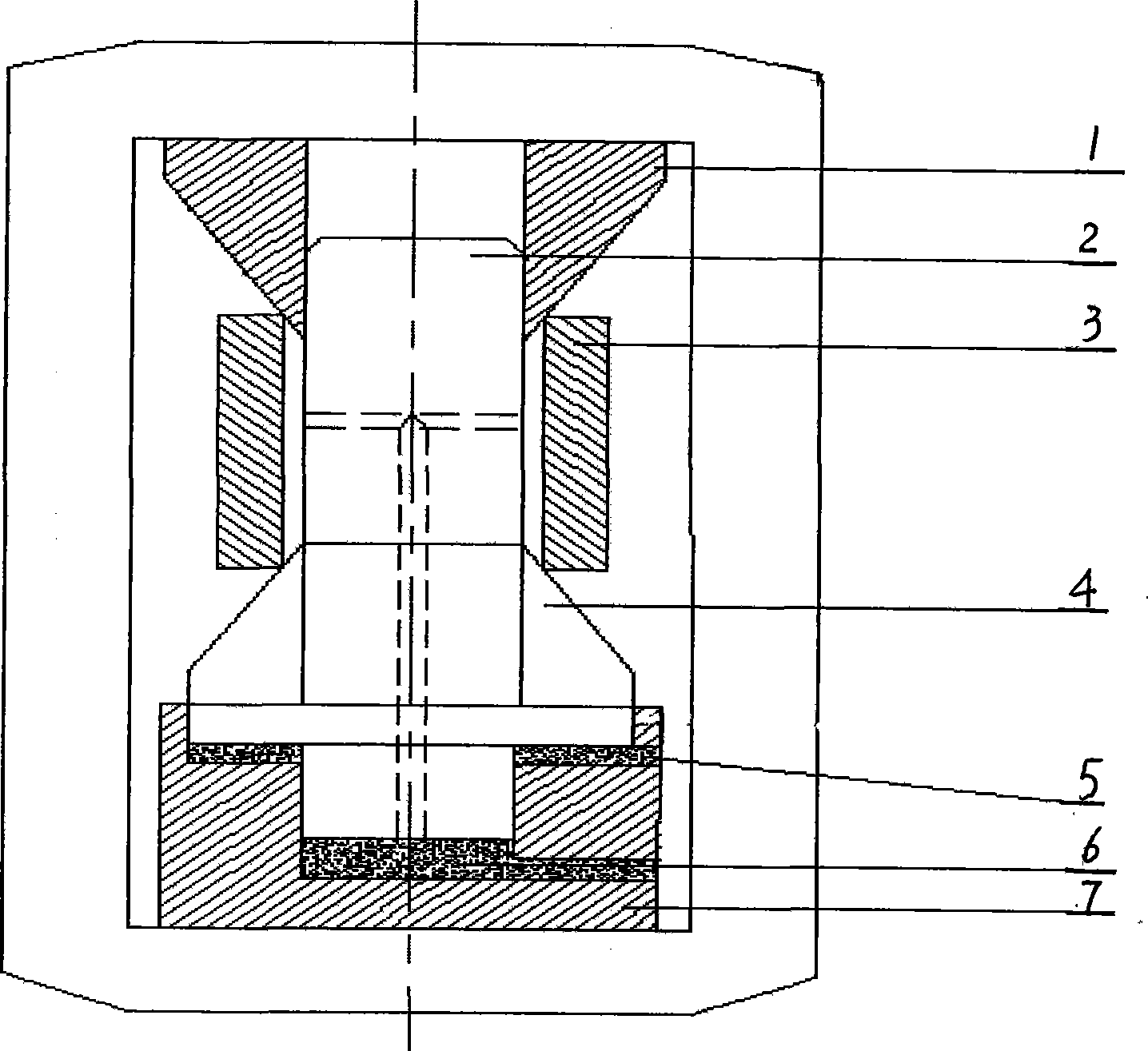

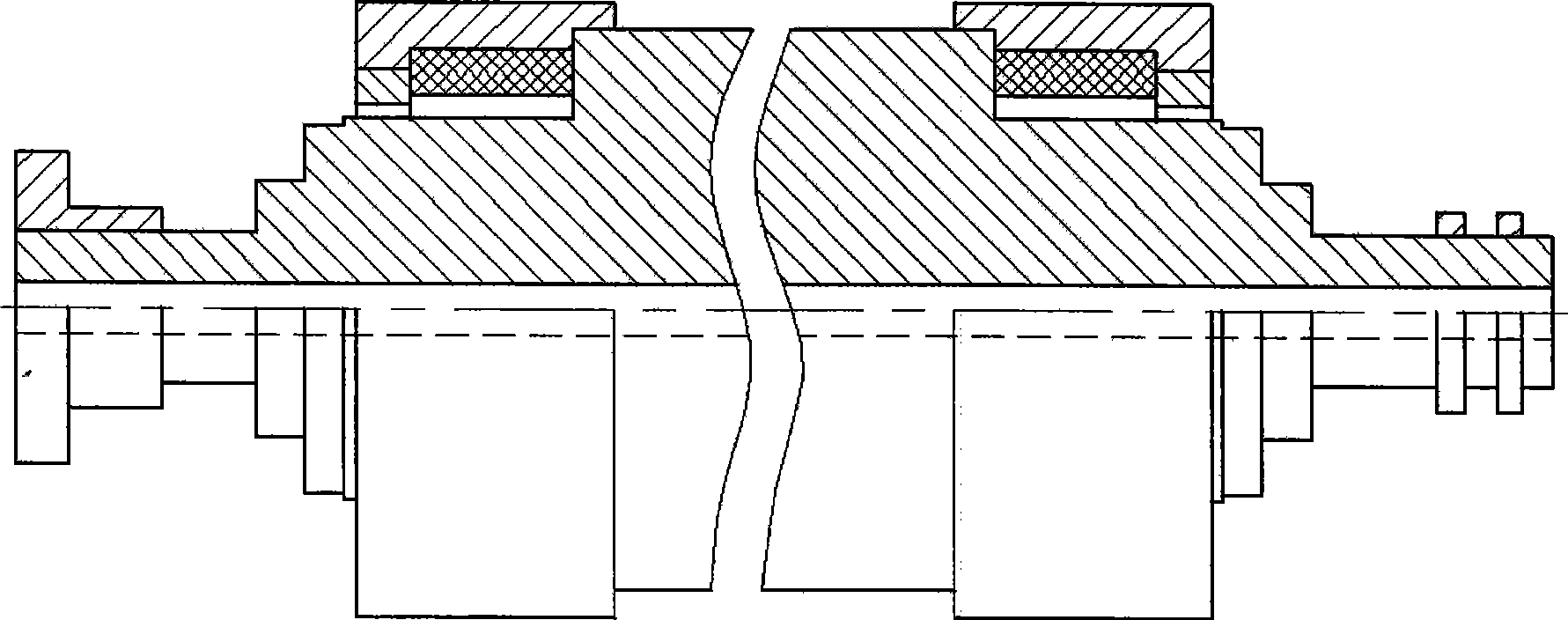

[0010] The hydraulic bulging strengthening process of replenishing liquid outside the retaining ring of the turbogenerator, the high-pressure liquid generated by the external high-pressure pump passes through the channel in the high-pressure cylinder, and then injects the fixed upper cone die and the moving die through the channel in the force-reducing column in the mold part. The closed space formed by the lower cone mold and the retaining ring makes the retaining ring plastically deformed under the action of liquid pressure, thereby achieving the purpose of strengthening the retaining ring; by adjusting the low pressure of the liquid in the low-pressure cylinder, the contact part between the retaining ring and the mold is adjusted. The size of the force is used to achieve the purpose of sealing and adjusting the shape and size of the retaining ring. The displacement sensor is used to monitor the bulging size of the retaining ring; the external hydraulic bulging strengthening p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com