Buckling test device for deepwater submarine conduit

A buckling test and submarine pipeline technology, applied in the field of submarine pipeline buckling test equipment, can solve problems such as no occurrence, and achieve the effects of ensuring safety, rapid pressure relief, and strong compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

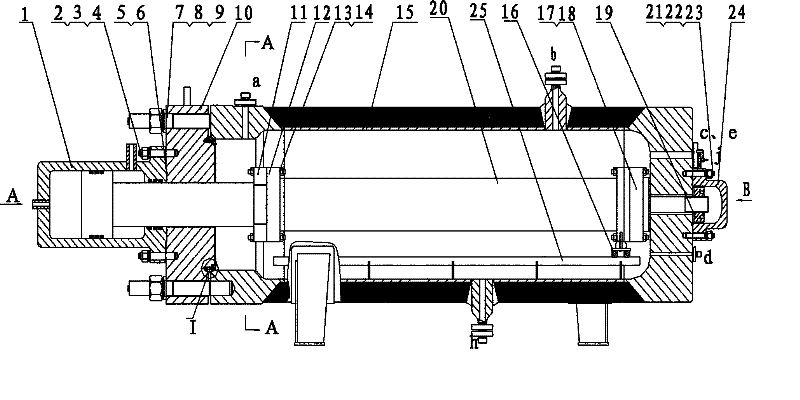

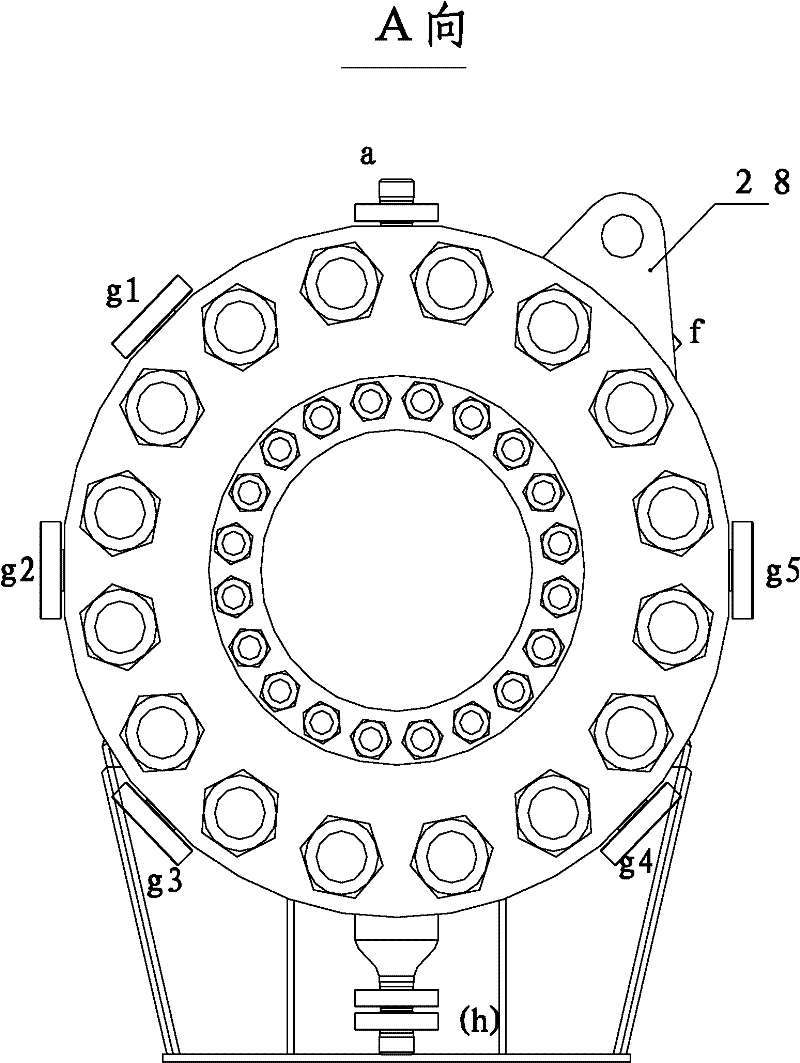

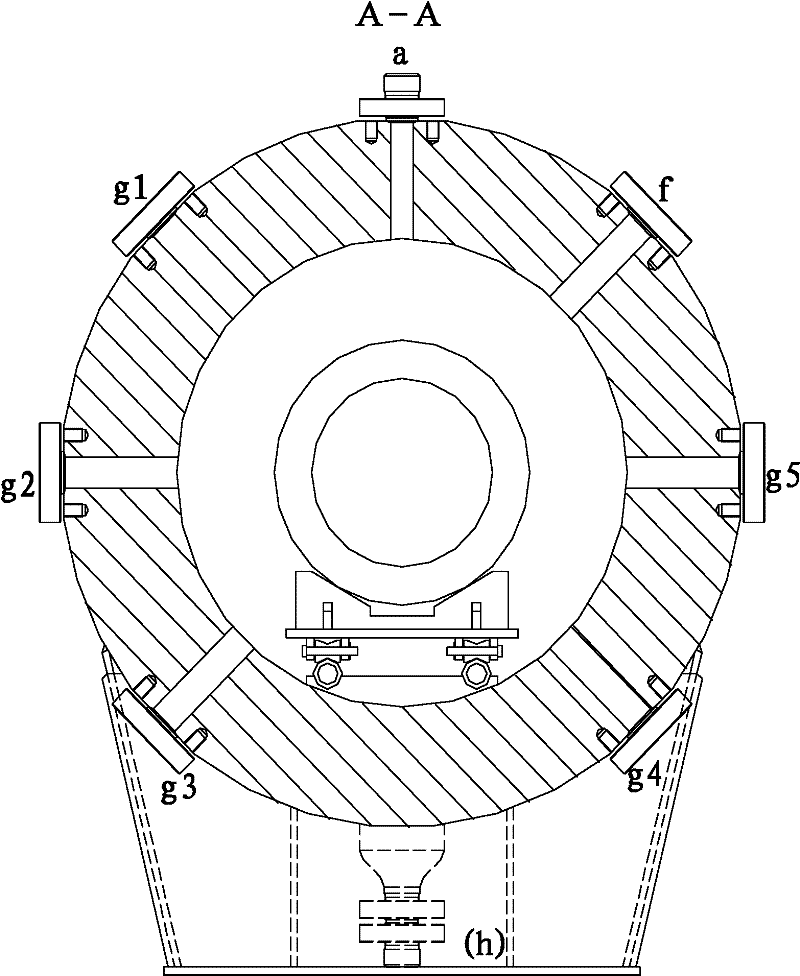

[0050] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the interior of the present invention can simulate the deep-sea high-pressure environment to carry out the deep-sea test piece test, and the equipped hydraulic machine can be used to apply axial force to the internal test piece. Its pressure bearing capacity is 43Mpa, the total length is 11.5 meters, and the diameter is 1.6 meters. It is installed horizontally. Water is used as the internal pressure medium. The present invention includes several main parts of the main cabin body 15, the front hatch cover 10, the cabin rear end hatch cover 24, and the cabin front end oil pressure system 1, which are used to simulate the deep sea pressure environment; System 1 applies axial tensile pressure to the pipeline test piece 20 placed in the cabin; in order to ensure the airtightness of the cabin, bolts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com