Composite stretch yarn sizing machine, composite stretch yarn and silk stockings

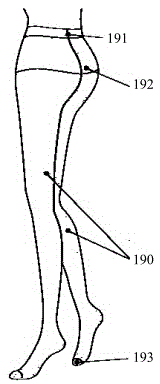

A technology of elastic yarn and high elastic yarn, applied in socks, pantyhose, liquid/gas/vapor yarn/filament processing and other directions, can solve the problems of poor reuse performance, elastic yarn breakage, chain reaction, etc. Achieve the effect of improving leg fatigue, preventing varicose veins, and good fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

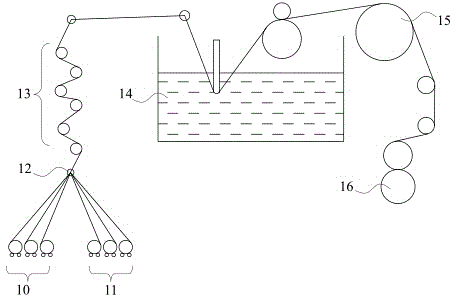

[0018] As shown in the figure, the composite elastic yarn sizing machine provided in this embodiment includes a plurality of high elastic yarn rollers 10 and a plurality of low elastic yarn rollers 11 driven by motors, located at the plurality of high elastic yarn rollers and The wire guide holes 12 and the tensioning device 13 on the rear side of a plurality of low-elastic yarn rollers are provided with a slurry pool 14 at the rear side of the tensioning device 13, and a heating roller 15 is arranged behind the slurry pool 14 and a heating roller is positioned at the heating roller. 15. The composite elastic yarn winding roller 16 on the rear side.

[0019] After the high elastic yarns on the plurality of high elastic yarn rollers 10 and the plurality of low elastic yarn rollers 11 and the low elastic yarns enter the guide wire hole, they enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com