Channel culvert formwork car

A formwork car and channel technology, applied in construction, artificial island, infrastructure engineering, etc., can solve the problems of long construction time, hidden safety hazards, high mechanical and labor costs, and achieve convenient movement, save construction costs, and speed up construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

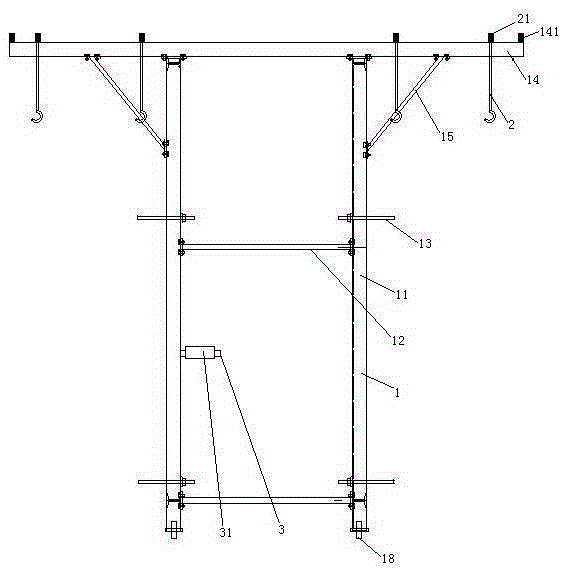

[0034] Embodiment one, see figure 1 , a channel culvert formwork vehicle, characterized in that it includes a vehicle frame 1. The frame 1 includes a pole 11 . The lower end of each vertical rod 11 is provided with road wheels 18 . Horizontally adjacent uprights are connected together by a number of transverse connecting rods 12 distributed along the up-down direction. The transverse connecting rod 12 and the upright rod 11 are detachably connected together by bolts fitting the connecting plate. Adjusting bolts 13 are provided on both sides of the vehicle frame 1 in the width direction (the left and right directions in the figure, the width direction of the channel culvert during use). Adjusting bolts 13 protrude from the vehicle frame 1 along the width direction of the vehicle frame. The adjusting bolt 13 is arranged on the pole 11 . The adjusting bolts 13 are at least distributed into two rows along the up-down direction, and distributed into two rows along the front-re...

Embodiment 2

[0042] Embodiment two, the difference with embodiment one is:

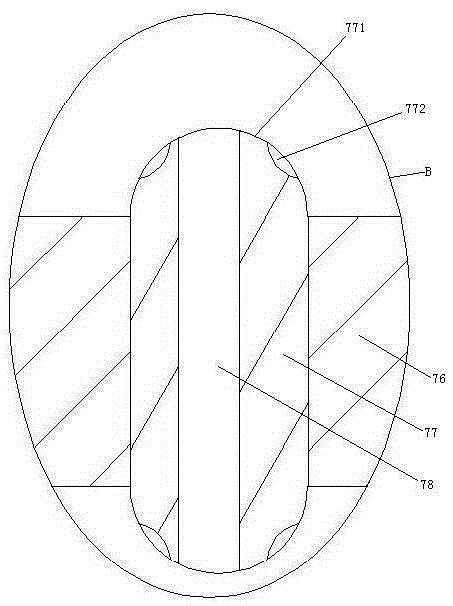

[0043] see Figure 6 , The vehicle frame 1 is provided with a static support foot 17 and a walking wheel installation rod 9 . Static support feet 17 and vehicle frame 1 are screwed together to realize liftable connection. The static support feet 17 can be adjusted to be lower than the walking wheels 18 . The road wheel mounting rod 9 includes a lower section 91 and an upper section 92 . The road wheels 18 are connected to the lower end of the lower section 91 . The upper end of the lower section 91 is slidably sleeved on the lower end of the upper section 92 . The lower section 91 is provided with a damping spring 93 supporting the upper section 92 . The upper end of the upper section 92 is provided with a connecting ring 921 . An inner ring 922 passes through the connecting ring 921 . The inner ring 922 is connected with the connecting ring 921 through the rubber ring 7 . The inner ring 922 is pierced wit...

Embodiment 3

[0050] Embodiment three, the difference with embodiment two is:

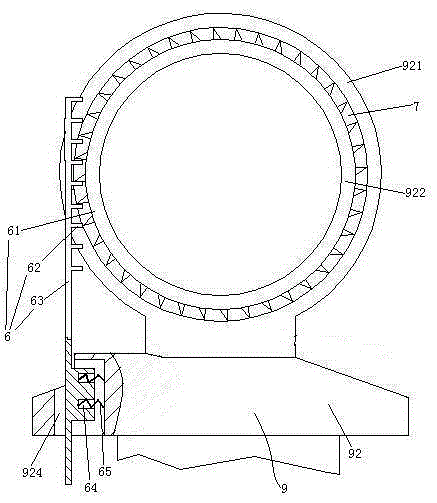

[0051] see Figure 11 , The road wheel mounting rod 9 is also provided with a drive mechanism 6. The inner ring 922 is rotatably connected to the rubber ring 7 , and the rubber ring 7 is fixedly connected with the connecting ring 921 .

[0052] The drive mechanism 6 includes a ratchet 61 , a pawl 62 for driving the ratchet, and a drive lever 63 . The ratchet 61 is coaxially connected with the inner ring 922 . The ratchet 61 is integrated with the inner ring 922 . The pawl 62 is fixedly connected to one end of the driving rod 63 . The upper section 92 is provided with a sliding hole 924 . The other end of the driving rod 63 can slide through the sliding hole 924 two-dimensionally. The lower end of the drive rod 63 is slidably hooked to the lower section 91 along the radial direction of the connecting ring 921 (see Figure 6 ) are fixed together. The driving rod 63 is provided with a storage hole 64 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com