Smelting method for removing fluorine and chlorine out of fluorine-and-chlorine-containing inferior zinc oxide and enriching valuable metals

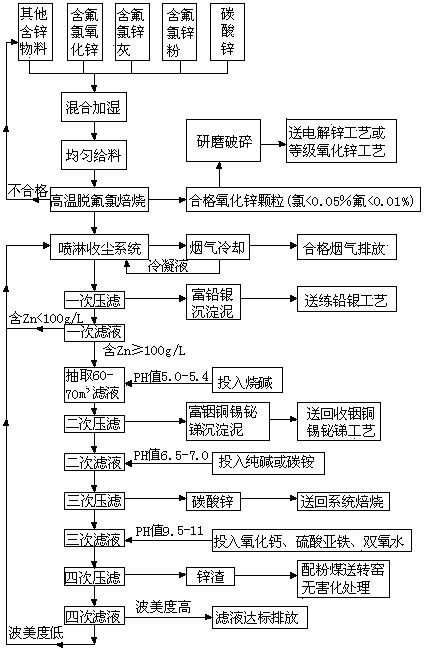

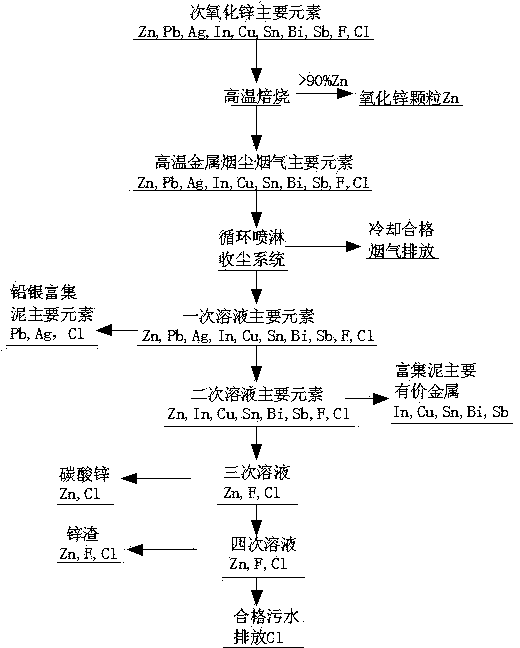

The technology of a valuable metal and a smelting method is applied in the smelting and fluorine-containing fields of zinc chlorohypoxide defluorination and enrichment of valuable metals, and can solve the problems of high investment and technical transformation cost, large pollution, and inability to unify technologies. To achieve the effect of reducing investment and technological transformation costs, reducing production costs and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Trial production is a 1:1 mixture of zinc-containing leaching slag, water-quenching slag, and steel plant gas mud used in a factory with coke powder, and a 1:1 mixture of sub-zinc oxide produced by the Wiltz method and zinc ash from a steel plant. It is still called secondary zinc oxide, and its main chemical composition is shown in Table 1:

[0048] Table 1 Main chemical components of secondary zinc oxide

[0049] element F% Cl% Zn% Bi% Pb% S% H2O% In g / T content 0.15 6.51 46.56 1.75 12.3 2.27 2.1 725 element Co% Ni% Zn% soluble Sn% Cu% Sb% Fe% Ag g / T content 0.003 0.0015 89.8 2.14 0.08 1.52 2.32 77

[0050] Use a coal tar burner to heat the Ф2.1m x 32m rotary kiln, and at the same time turn on the circulating spray water system, control the air volume of the induced draft fan at the tail of the spray system, and maintain the rotary kiln in a slightly negative pressure state. When the temperatur...

Embodiment 2

[0072] The 1:1 mixture of zinc dust and dust collection dust produced by the electroplating factory and alloy factory for trial production is still called secondary zinc oxide after synthesis. Its main chemical composition is shown in Table 10:

[0073] Table 10 main chemical components of zinc oxide

[0074] element F% Cl% Zn% Bi% Pb% S% H2O% In g / T content 0.35 3.51 56.12 0.01 1.3 0.22 1.55 -- element Co% Ni% Zn% soluble Sn% Cu% Sb% Fe% Ag g / T content 0.22 0.13 92.8 0.07 0.01 0.01 5.32 --

[0075] Use a coal tar burner to heat the Ф2.1m x 32m rotary kiln, and at the same time turn on the circulating spray water system, control the air volume of the induced draft fan at the tail of the spray system, and maintain the rotary kiln in a slightly negative pressure state. When the temperature of the kiln head rises to ≥1200°C, and the temperature of the kiln tail is ≥300°C; at this time, spray and humidify t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com