Waste lead recovering method for lead-acid storage batteries

A lead-acid battery, lead recycling technology, applied in photography technology, instruments, photography auxiliary technology and other directions, can solve the problems of high energy consumption and serious pollution, achieve low energy consumption, high recycling rate, and reduce the discharge of waste liquid Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

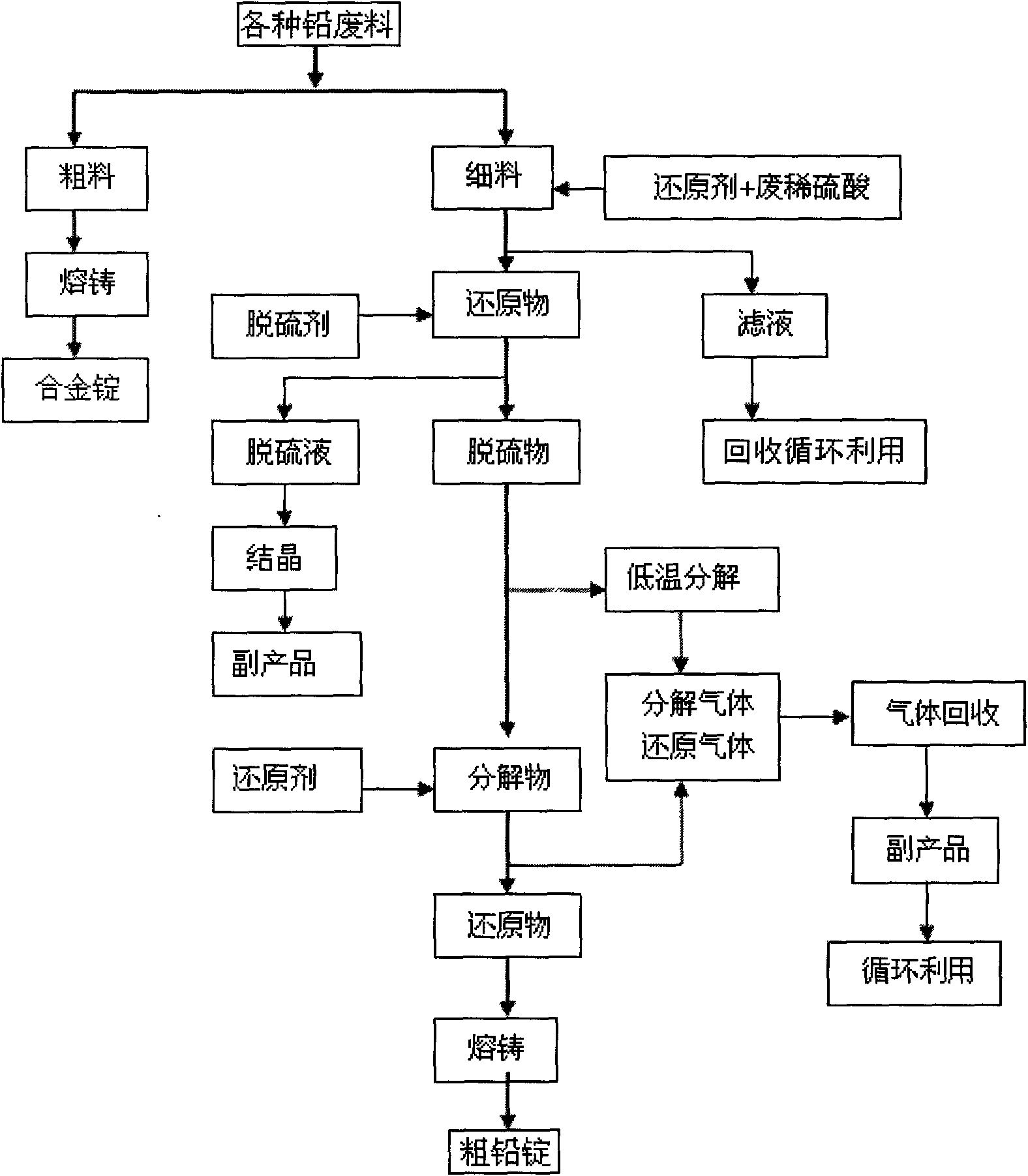

Image

Examples

Embodiment Construction

[0023] (1) Sorting the lead waste first, and dividing them into coarse and fine materials; coarse materials include busbars, grids, and poles, which are directly melted into ingots; fine materials include lead paste, waste lead powder generated during production, and lead slag, lead mud;

[0024] (2) Get 1000 kilograms of the fine material that step (1) obtains and add in the reactor that stirrer is arranged, add reducing agent FeSO in the reactor simultaneously 4 300 kg, specific gravity 1.2g / cm 3 Dilute sulfuric acid 200L, stir and react at 50-60°C for 50-70 minutes, reduce lead dioxide to lead sulfate, a low-valence lead compound, filter the reacted material to obtain 1200 kg of solid lead sulfate, and recycle the filtrate ;

[0025] (3) Add 1,000 kilograms of lead sulfate obtained in step (2) into a reactor with a stirring device, add 800 kilograms of water to make a slurry, then add 350 kilograms of desulfurizing agent sodium carbonate for desulfurization treatment. Do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com