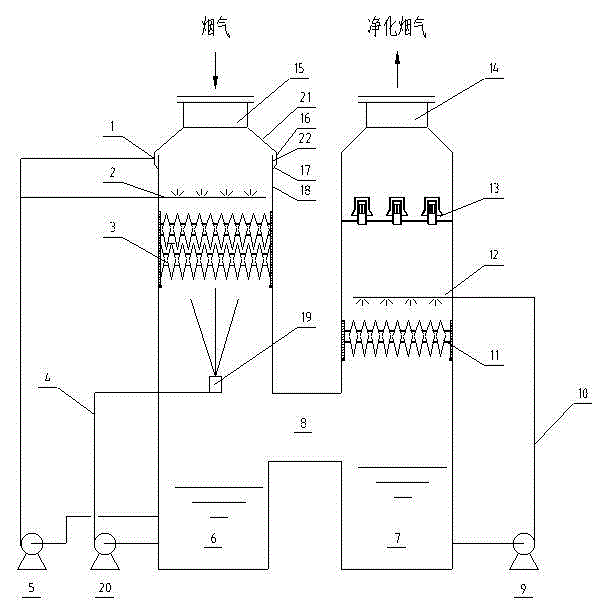

H-shaped flue gas dust removal desulfurization tower and flue gas desulfurization method

A desulfurization process and desulfurization tower technology, which are applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of easy blockage of the return line, large footprint, and unsuitability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

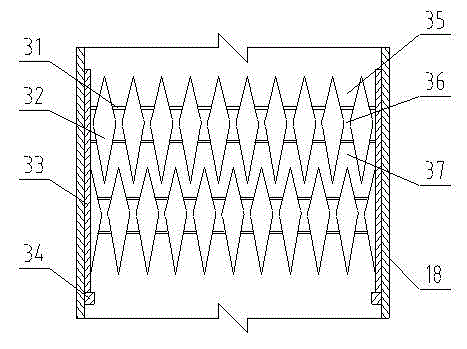

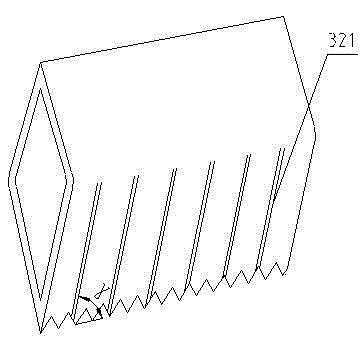

[0059] A high-temperature flue gas temperature is 180°C, and the gas volume is 160,000Nm 3 / h,SO 2 The concentration is 500mg / Nm 3 , dust concentration 300mg / Nm 3 .

[0060] Reactor operating conditions: operating temperature is 170°C, operating pressure is normal pressure, the pH value of the primary absorption liquid is 6-7, and the pH value of the secondary absorption liquid is 8-9. The turbulent liquid-gas ratio is 6:1, NaOH solution is used as the absorbent, and the gas-liquid is in countercurrent contact; the packing assembly operates with a liquid-gas ratio of 3:1.

[0061] After being treated by the method of the invention, the flue gas temperature is 50°C, the desulfurization efficiency is 98%, and the dust removal efficiency is 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com