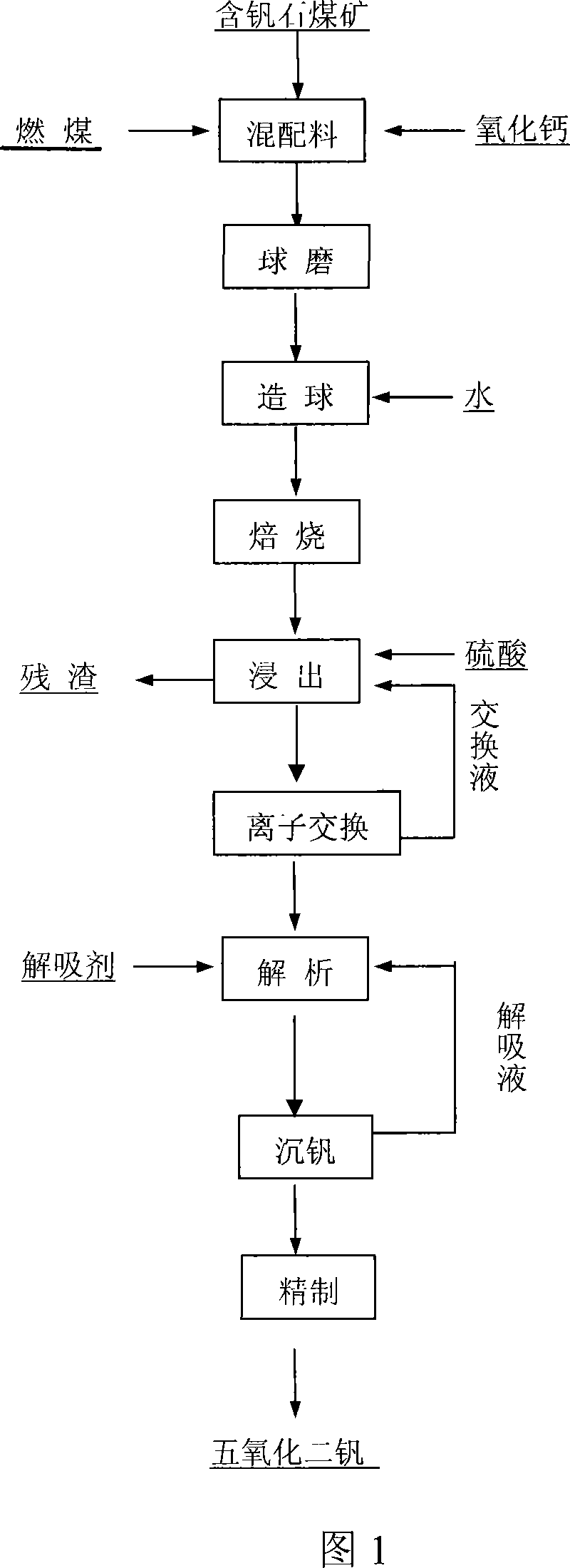

Process of extracting vanadium pentoxide from coal gangue

A technology of vanadium pentoxide and stone coal mines, applied in the direction of vanadium oxide, etc., can solve the problem of insufficient purity and achieve the effects of high product purity, simplified process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 120g of calcium oxide (CaO ≥ 90%) and 100g of anthracite (C ≥ 80%) to 2000g of dry stone coal, grind and mix evenly, add 200g of water to make pellets, the diameter of which is about 20mm, and place them in the air to dry naturally Then put it into a high-temperature furnace connected to the air for roasting, the roasting temperature is 980°C, and the roasting time is 3 hours to obtain cooked balls, take out the cooked balls and place them in the air to cool to room temperature, divide them into two parts on average, and record them as cooked balls I and cooked balls respectively. Ball II. Soak cooked balls I with 1060g of sulfuric acid solution with a concentration of 10%. After soaking for 48 hours, soak cooked balls II with the obtained leachate until the pH value of the leachate reaches 1.5, filter, and the filtrate is ion-exchanged with AMBERLITE IRA96RF anion exchange resin, resin adsorption After saturation, use 1.5mol / L NH 4 Cl and 0.2mol / L NH 3 ·H 2 O mi...

Embodiment 2

[0038] Add 160g of calcium oxide (CaO ≥ 90%) and 200g of anthracite (C ≥ 80%) to 2000g of dry stone coal, grind and mix evenly, add 260g of water to make pellets, the diameter of which is about 15mm, and place them in the air to dry naturally Then put it into a high-temperature furnace connected to the air for roasting, the roasting temperature is 950°C, and the roasting time is 4 hours to obtain cooked balls, take out the cooked balls and cool them to room temperature in the air, divide them into two parts on average, and record them as cooked balls I and cooked balls respectively. Ball II. Use 1060g of sulfuric acid solution with a concentration of 15% to soak cooked balls I, soak for 48 hours, then soak cooked balls II with the obtained leachate until the pH value of the leachate reaches 2.0, filter, and the filtrate is ion-exchanged with AMBERLITE IRA96CRF anion exchange resin. After the adsorption is saturated, use 2mol / L NH 4 Cl and 0.5mol / L NH 3 ·H 2 O mixed solution...

Embodiment 3

[0040] Add 300g of calcium oxide (CaO ≥ 90%) and 450g of anthracite (C ≥ 80%) to 3000g of dry stone coal, grind and mix evenly, add 450g of water to make pellets, the diameter of which is about 12mm, and place them in the air to dry naturally Then put it into a high-temperature furnace connected to the air for roasting. The roasting temperature is 960° C., and the roasting time is 5 hours to obtain cooked balls. The cooked balls are taken out and placed in the air to cool to room temperature. Ball II and Cooking Ball III. Soak cooked ball I with 2000g of sulfuric acid solution with a concentration of 20%, soak for 48 hours, then soak cooked ball II with the obtained leachate, and then soak cooked ball III after 24 hours, until the pH value of the leachate reaches 3.0, filter, and use AMBERLITE IRA96RF anion for the filtrate The exchange resin was used for ion exchange, and after the resin was saturated, 2.5mol / L NH 4 Cl and 0.8mol / L NH 3 ·H 2 O mixed solution for desorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com