Barium sulfate based polybasic composite white pigments and method for preparing same

A multi-component composite, white pigment technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of high manufacturing cost, shortage of high-quality titanium resources, high sales price, etc., to achieve low production cost, Good dispersibility and scratch resistance, fine particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

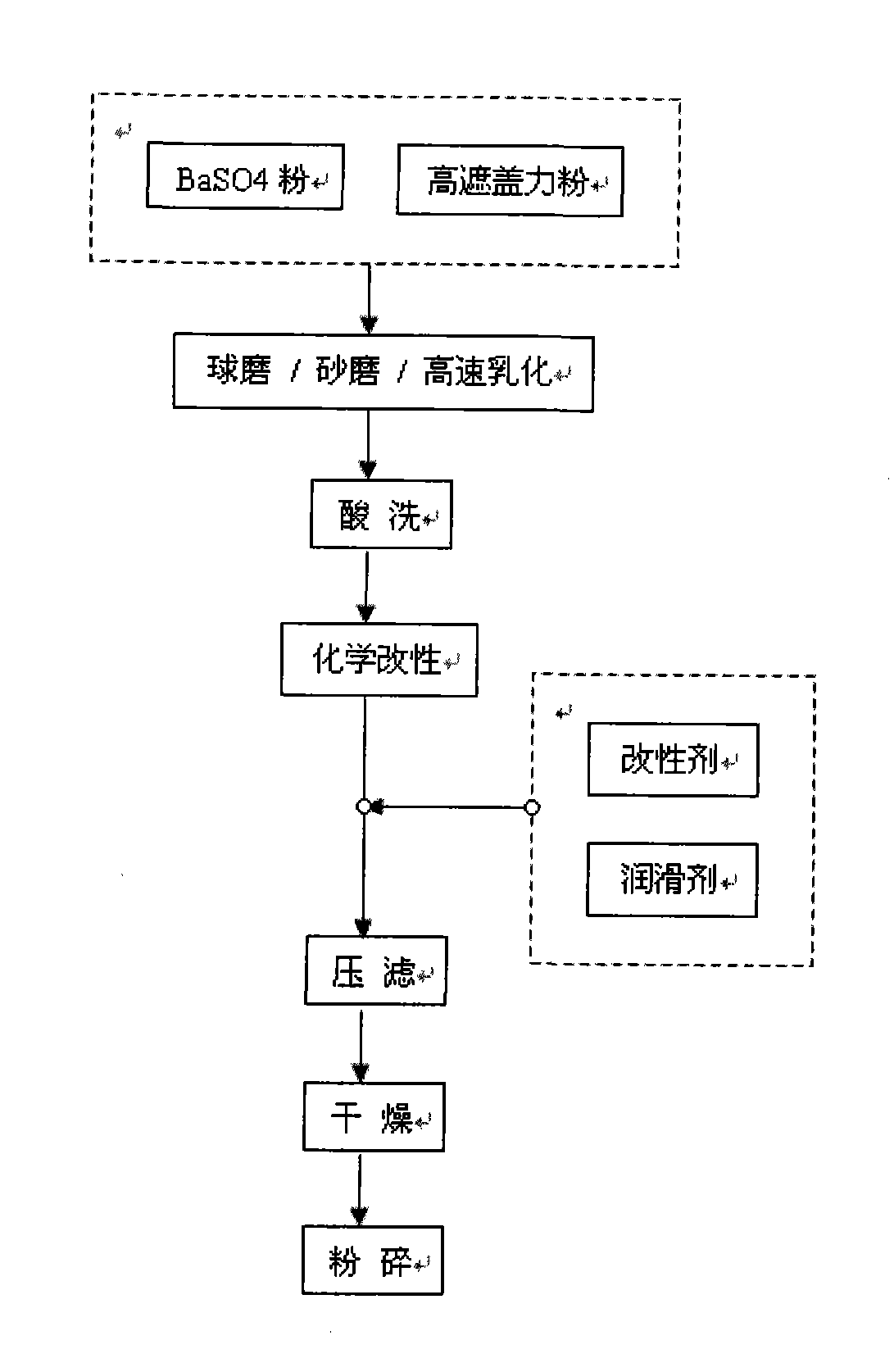

[0037] Embodiment 1: as figure 1 as shown,

[0038] A. Weigh 100g of barite ore powder with an average particle size of 1μm and 900mL of distilled water, add them into the reactor, then add 0.5g of sodium polyphosphate, and then stir. After the barite ore powder is uniformly dispersed, add Sulfuric acid adjusts the pH to 5;

[0039] B. Mix 1g of titanium dioxide, 0.5g of silane coupling agent KH 550 (Nanjing Shuguang Chemical Group Co., Ltd.), and 0.1g of stearic acid into the product of step A at room temperature; Particle size 50nm;

[0040] C. Put the ball-milled product into a plate filter press to remove water, and then dry it at 60°C. Then, the dried material is sent into a pulverizer for processing, and the barium sulfate-based multi-element composite white pigment can be prepared.

Embodiment 2

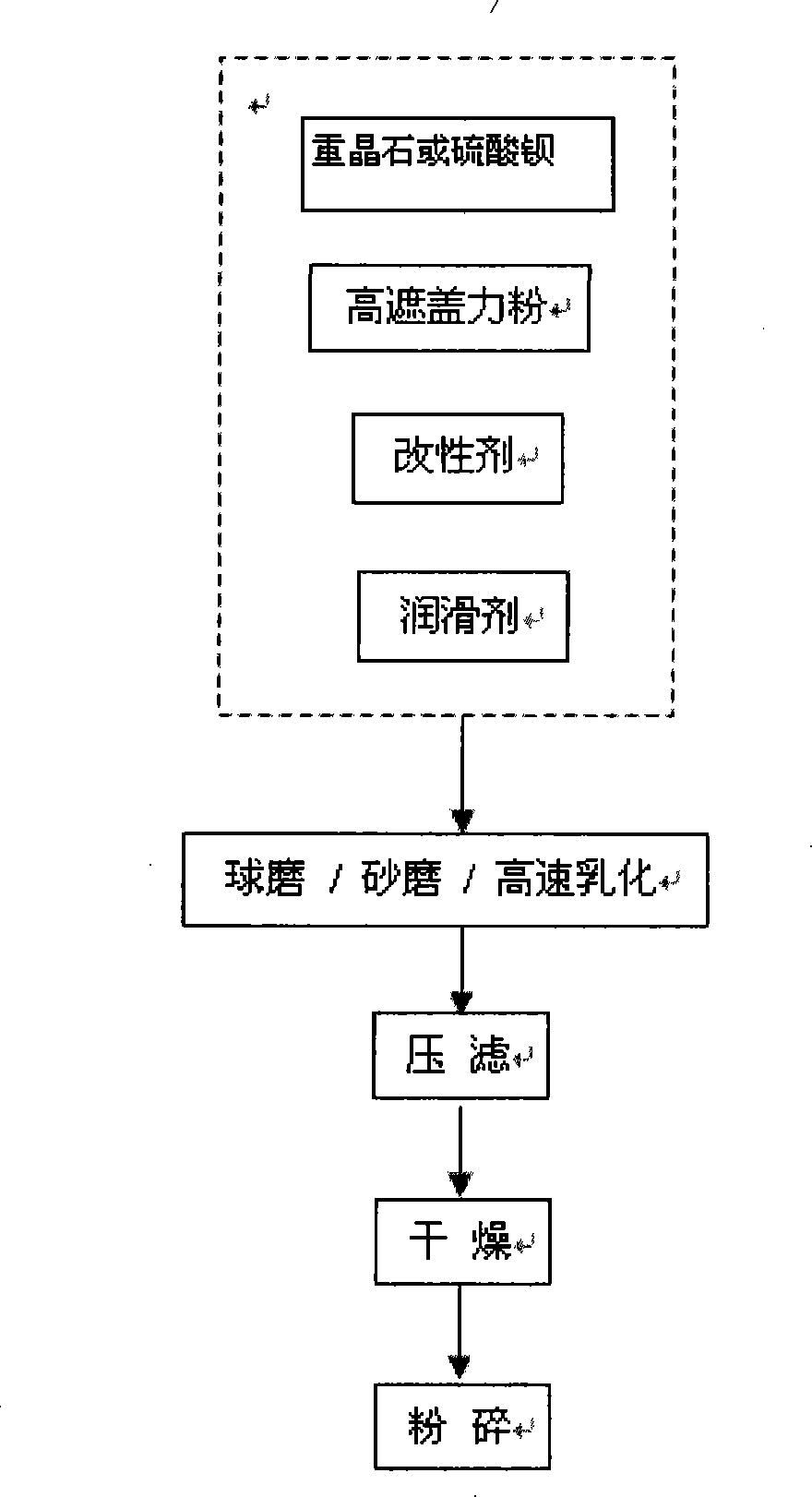

[0042] A. Weigh 100g of barite ore powder and 400mL of distilled water with an average particle size of 5 μm respectively, add them to the reactor, add 1g of sodium hexametaphosphate, and then stir. After the barite ore powder is uniformly dispersed, add sulfuric acid to dissolve the pH adjusted to 6;

[0043] B, 5g silicon dioxide, 1g silane coupling agent KH 560 (Nanjing Shuguang Chemical Group Co., Ltd.), 0.5g stearic acid, after mixing uniformly at room temperature, add in the product of step A; then put into a ball mill and ball mill until Average particle size 80nm;

[0044] C. Put the ball-milled product into a plate filter press to remove water, and then dry it at 80°C. Then, the dried material is sent into a pulverizer for processing, and the barium sulfate-based multi-element composite white pigment can be prepared.

Embodiment 3

[0046] A. Weigh 100g of barite ore powder with an average particle size of 10μm and 250mL of distilled water, add them into the reactor, add 2g of sodium polyacrylate, and then stir. After the barite ore powder is dispersed evenly, add a certain amount of Sulfuric acid, stir evenly, adjust the pH value to 7;

[0047] B. Mix 10g zirconium dioxide, 2g titanate coupling agent NDZ 201 (Nanjing Shuguang Chemical Group Co., Ltd.), and 1g sodium stearate into the product of step A after mixing uniformly at room temperature; put the composite slurry Ball mill in a sand mill to an average particle size of 1 μm;

[0048] C. Put the ball-milled product into a plate filter press to remove water, and then dry it at 100°C. Then, the dried material is sent into a pulverizer for processing, and the barium sulfate-based multi-element composite white pigment can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com