Method for preparing biomass carbon-based composite energy storage material by utilizing plant fiber

A technology of composite energy storage materials and biomass carbon, which is applied in the field of comprehensive utilization of natural plant fibers and can solve problems such as difficulties in large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of nano nickel hydroxide

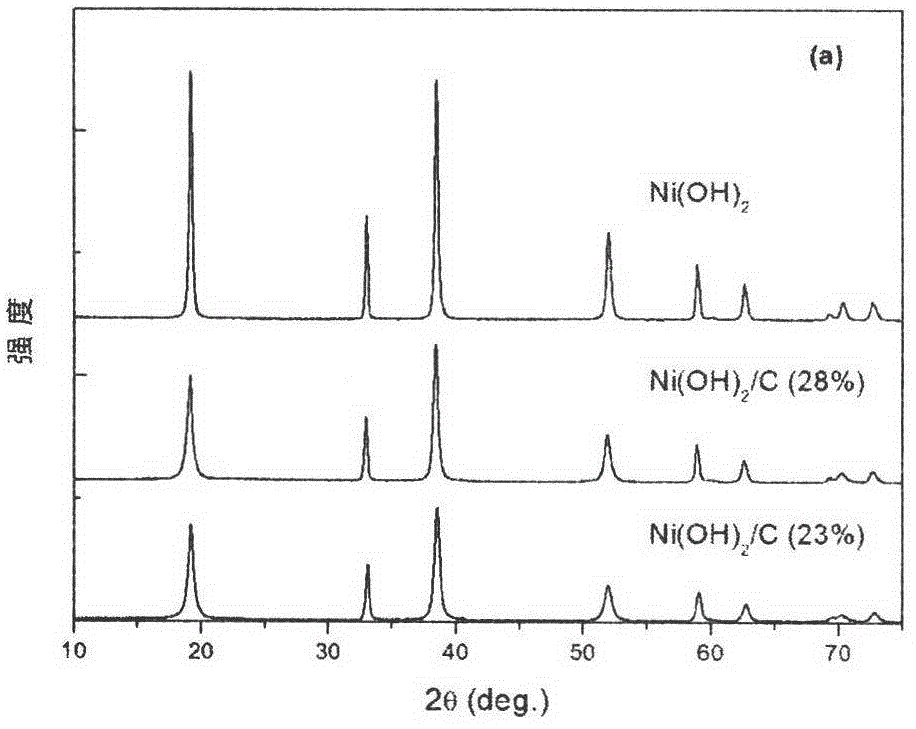

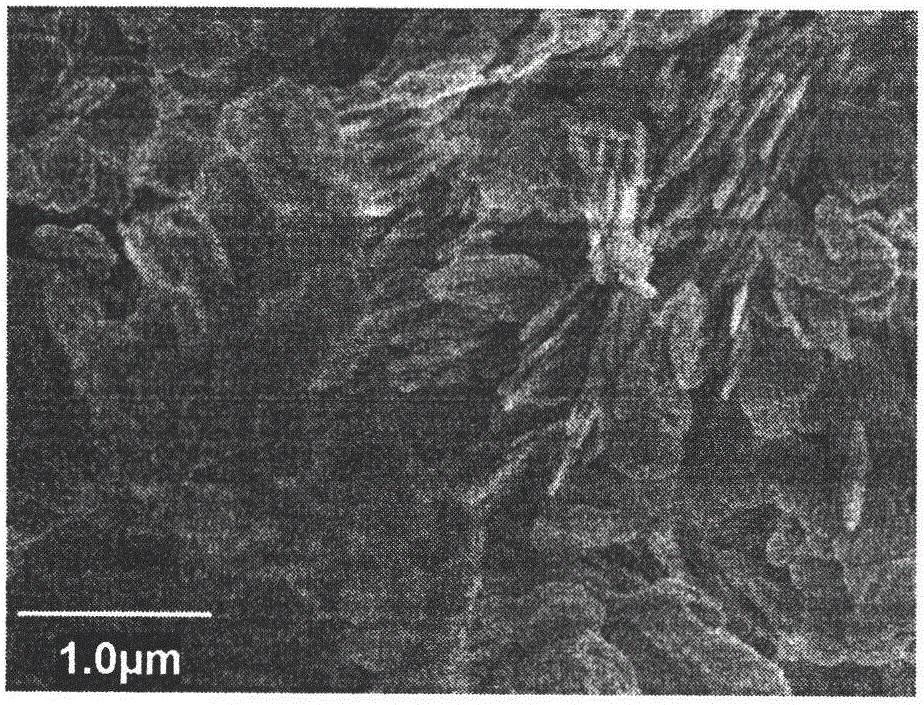

[0022] Measure 80 ml of 0.6 mol / L nickel chloride aqueous solution, and add concentrated ammonia water drop by drop under stirring until the pH of the solution is 9. After stirring for 30 minutes, the mixture was transferred to an autoclave for hydrothermal reaction at 200° C. for 48 hours. Naturally cool to room temperature, centrifuge, and obtain nano-sheet nickel hydroxide after washing and drying (see image 3 ). X-ray powder diffraction spectrum ( figure 1 ) is consistent with the standard spectrum of β-nickel hydroxide (JCPDS No.14-01117); the diffraction peak is narrow and has good crystallinity, and the average particle size calculated by the Scherrer formula is about 34.3nm; no impurity diffraction peak , high purity.

Embodiment 2

[0023] Embodiment 2: one-step hydrothermal synthesis of nickel hydroxide / biomass carbon (23%) composite material

[0024] Take 1.0 g of peanut shells, wash them, dry them, crush them mechanically, and then ultrasonically crush them in 150 ml of distilled water. The suspension was magnetically stirred and heated to 50° C., 80 ml of 0.5 mol / L nickel chloride aqueous solution was added dropwise, and the stirring was continued for 30 minutes. The reaction mixture was cooled to room temperature, and concentrated aqueous ammonia was added dropwise until the pH of the solution was 9. After stirring for 30 minutes, the mixture was transferred to an autoclave for hydrothermal reaction at 200° C. for 48 hours. Cool naturally to room temperature, centrifuge, wash and dry to obtain a nickel hydroxide / biomass carbon composite material, and the thermogravimetric analysis shows that the carbon content is 23%. X-ray powder diffraction spectrum (see figure 1 ) is consistent with the standar...

Embodiment 3

[0025] Embodiment 3: Two-step hydrothermal synthesis of nickel hydroxide / biomass carbon (28%) composite material

[0026] Take 1.0 g of peanut shells, wash them, dry them, crush them mechanically, and then ultrasonically crush them in 150 ml of distilled water. The above suspension was subjected to a hydrothermal reaction at 200° C. for 48 h in an autoclave. Cool naturally, centrifuge, and ultrasonically disperse in distilled water after washing to obtain a biomass carbon suspension. According to the mass ratio of 7:3 (nickel hydroxide / biomass carbon), 0.5 mol / L nickel chloride aqueous solution was added dropwise, and the stirring was continued for 30 minutes. The reaction mixture was cooled to room temperature, and concentrated aqueous ammonia was added dropwise until the pH of the solution was 9. After stirring for 30 minutes, the mixture was transferred to an autoclave for hydrothermal reaction at 200° C. for 48 hours. Naturally cool to room temperature, centrifuge, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com