Preparation method of N-P-codoping porous biomass carbon catalyst

A biomass carbon, co-doping technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of unreasonable utilization of biomass resources, adjustable and uniform catalysts It has problems such as poor performance and difficult to control stability, and achieves the effect of good industrial application prospects, good resistance to methanol poisoning and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Catalyst 50%P(Ph) 3 Preparation of -800-0.5-1

[0030] a. Preparation of doping material: ultrasonically dissolve 1.0g chitosan in 30mL 0.5M FeCl 3 In the solution, stir magnetically at 50°C for 6h, add 0.5g of triphenylphosphine, stir magnetically until uniformly dispersed, place the mixture in a 50mL polytetrafluoroethylene liner, react hydrothermally at 140°C for 20h, and filter out The solid was washed 3 to 5 times with deionized water, centrifuged and dried in vacuum for 12 hours to obtain 0.68 g of doped material.

[0031] b. 50%P(Ph) 3 - Preparation of 800-0.5-1: Grinding the dopant material obtained in the above a. and mixing it with 0.68g ZnCl 2 (mass ratio 1:1) mixed, then carbonized at 800°C for 1h in a nitrogen atmosphere, and the resulting carbon material was refluxed with 1M HCl at 60°C for 2h to remove excess ZnCl 2 , the resulting product was washed with deionized water, centrifuged, dried overnight, and ground to obtain 50% P(Ph) 3 -800-0.5-1 Bi...

Embodiment 2

[0035] 1. Catalyst 50%P(Ph) 3 Preparation of -900-0.5-1

[0036] a. Preparation of doping material: ultrasonically dissolve 1.0g chitosan in 30mL0.5MFeCl 3 In the solution, stir magnetically at 50°C for 6h, add 0.5g of triphenylphosphine, stir magnetically until uniformly dispersed, place the mixture in a 50mL polytetrafluoroethylene liner, react hydrothermally at 140°C for 20h, and filter out The solid was washed 3 to 5 times with deionized water, centrifuged and dried in vacuum for 12 hours to obtain 0.60 g of doped material.

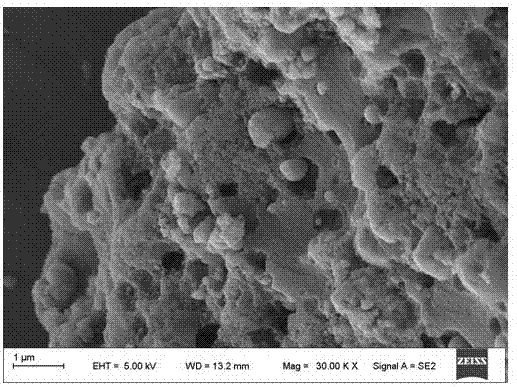

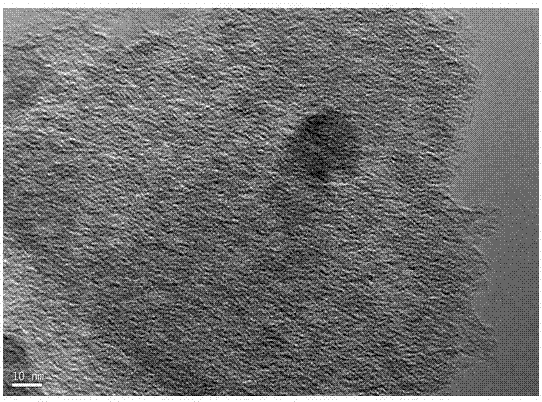

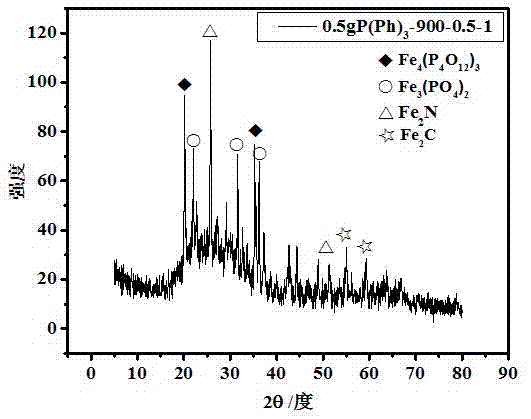

[0037] b. 50%P(Ph) 3 -Preparation of 900-0.5-1: Grind the doped material obtained in above a and mix with 0.60g ZnCl 2 (1:1) mixed, then carbonized at 900°C for 1h in a nitrogen atmosphere, and the resulting carbon material was refluxed with 1M HCl at 60°C for 2h to remove excess ZnCl 2 , the resulting product was washed with deionized water, centrifuged, dried overnight, and ground to obtain 50% P(Ph) 3 -900-0.5-1 Biomass carbon material.

[00...

Embodiment 3

[0041] 1. Catalyst 100%P(Ph) 3 Preparation of -900-0.5-1

[0042] a. Preparation of doping material: ultrasonically dissolve 1.0g chitosan in 30mL0.5MFeCl 3 In the solution, stir magnetically at 50°C for 6h, add 1.0g of triphenylphosphine, stir magnetically until uniformly dispersed, place the mixture in a 50mL polytetrafluoroethylene liner, react hydrothermally at 140°C for 20h, and filter out The solid was obtained as a crude product, washed 3 to 5 times with deionized water, centrifuged and dried in vacuum for 12 hours to obtain 0.72 g of doped material.

[0043] b. 100%P(Ph) 3 The preparation of -900: with embodiment 2.

[0044] 2. Oxygen reduction test

[0045] Test condition and method are with embodiment 1, and test result is as Figure 8 shown. Depend on Figure 8 It can be seen that when the rotation speed of the rotating disk electrode is 1600rmp, the oxygen reduction onset potential is -0.122V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com