Multi-functional biomass carbon fertilizer produced by using biomass carbon from straws and kitchen waste

A technology for kitchen waste and biomass charcoal, which is applied in the application, fertilization device, fertilizer mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

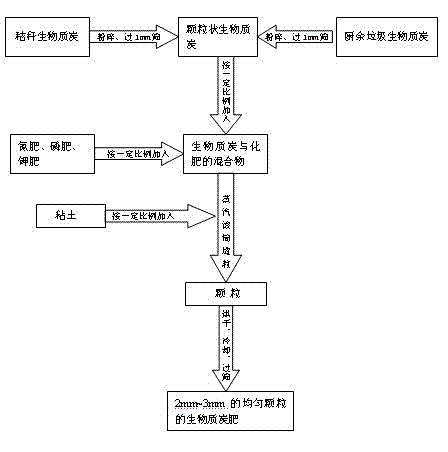

Method used

Image

Examples

Embodiment 1

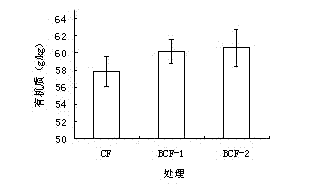

[0023] The field test of rice biochar fertilizer in Chizhou, Anhui Province, the following treatments were set up in the test: 1) Conventional fertilization (CF): 25 kg / mu of compound fertilizer was applied as base fertilizer, and 10 kg of urea was applied; 2) Biochar fertilizer treatment 1 (BCF1): charcoal Base fertilizer 28 kg / mu as base fertilizer, topdressing 10 kg urea; 3) Biochar fertilizer treatment 2 (BCF2): carbon-based fertilizer 30kg / mu as base fertilizer, topdressing 15 kg urea for 3 treatments, each treatment repeated 3 times, The area of the plot is 15m 2 , 32 plants per treatment, arranged in random blocks. There are 1m wide protective rows between the plots. The soil organic matter content of biochar fertilizer was 4%~5% higher than that of purified fertilizer. (refer to figure 2 ).

[0024] The biochar fertilizer described therein is obtained by the following steps:

[0025] 1. Pyrolysis of straw or kitchen waste to produce biochar

[0026] Collect c...

Embodiment 2

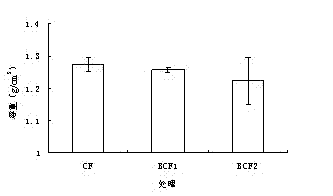

[0033] Cotton biochar fertilizer test in Chizhou, Anhui, the test set up the following treatments: 1) Conventional fertilization (CF): 15 kg / mu of compound fertilizer was applied as base fertilizer, followed by 15 kg of compound fertilizer, 15 kg of urea and 10 kg of potassium fertilizer; 2) biochar Fertilizer treatment 1 (BCF1): 16.8 kg / mu of carbon-based fertilizer as base fertilizer, followed by 15 kg of compound fertilizer, 15 kg of urea and 10 kg of potassium fertilizer; 3) Biochar fertilizer treatment 2 (BCF2): 30kg / mu of carbon-based fertilizer Base fertilizer, 15 kg compound fertilizer, 15 kg urea and 10 kg potash fertilizer; 3 treatments, each treatment repeated 3 times, the plot area is 15m 2 , 32 plants per treatment, arranged in random blocks. There are 1m wide protective rows between the plots. CF soil bulk density is 1.30~1.27g / cm 3 , BCF1 is 1.25~1.27 g / cm 3 , BCF2 is 1.15~1.29 g / cm 3 , the bulk density increased by 3%~4%. (refer to image 3 );

[0034] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com