Preparation method of biomass carbon composite material for removing phosphorus in wastewater

A technology of biomass carbon and composite materials, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of high equipment requirements, high reaction temperature, harsh conditions, etc., and achieve low cost, Mild reaction conditions and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

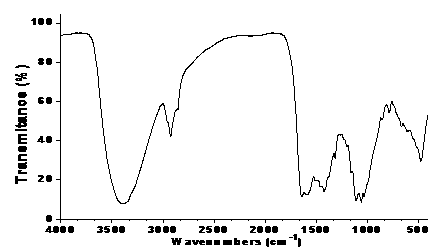

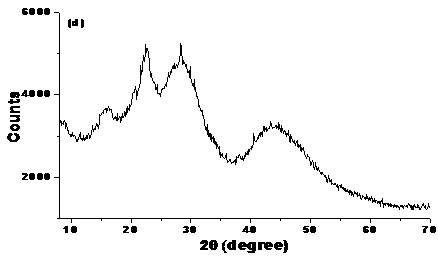

Method used

Image

Examples

Embodiment 1

[0025] Add 30 mL of 0.01 M LaCl to a 50 mL Teflon jar 3 Add 1.5g of rice straw to the solution, stir thoroughly for 30min, add 0.3mL 1M KOH, continue stirring for 30min, and finally hydrothermally carbonize at 140°C for 4h. After the hydrothermal carbonization was completed, the hydrothermal reaction kettle was taken out from the oven, cooled to room temperature in the air, and the resulting product was filtered with a 0.45 μm filter membrane, and then washed twice with deionized water and ethanol respectively, and then heated at 60 Dry at ℃ to constant weight, pass through a 40-mesh sieve for later use.

Embodiment 2

[0027] Add 30 mL of 0.1 M LaCl to a 50 mL Teflon jar 3 solution, add 4.5 g of rice straw, stir thoroughly for 30 min, add 4.5 mL of 3M KOH, continue stirring for 80 min, and finally hydrothermally carbonize at 200 °C for 30 h. After the hydrothermal carbonization was completed, the hydrothermal reaction kettle was taken out from the oven, cooled to room temperature in the air, and the obtained product was filtered with a 0.45 μm filter membrane, and then washed twice with deionized water and ethanol respectively, and then heated at 105 Dry at ℃ to constant weight, pass through a 120-mesh sieve for later use.

Embodiment 3

[0029] Add 30 mL of 0.2 M CaCl to a 50 mL Teflon jar 2 Add 6g of kitchen waste to the solution, stir thoroughly for 30 minutes, then add 7.5 mL of 6M KOH, continue stirring for 120 minutes, and finally hydrothermally carbonize at 280°C for 48 hours. After the hydrothermal carbonization is completed, the hydrothermal reaction kettle is taken out from the oven, cooled to room temperature in the air, and the resulting product is filtered with a 0.45 μm filter membrane, and then washed twice with deionized water and ethanol respectively, and then heated at 120 Dry at ℃ to constant weight, pass through a 180-mesh sieve for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com